3632828

Lubricating Oil Transfer Tube

Cummins®

AVAILABLE

4 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Lubricating Oil Transfer Tube 3632828, manufactured by Cummins, is a critical component in the lubrication system of commercial trucks. This tube ensures the efficient transfer of lubricating oil within the engine, contributing to the engine’s performance and longevity.

Basic Concepts of Lubricating Oil Transfer Tubes

A Lubricating Oil Transfer Tube is essential for the smooth and consistent flow of oil to various engine components. This tube is vital for reducing friction and wear, thereby enhancing the engine’s durability and efficiency 1.

Purpose and Role in Truck Operation

The Lubricating Oil Transfer Tube 3632828 ensures optimal engine performance by distributing oil evenly throughout the engine. This consistent oil flow aids in cooling engine components, reducing wear and tear, and extending the engine’s operational lifespan.

Key Features

This Cummins part is constructed from durable materials to withstand high pressures and temperatures. Its design includes precise fittings and connections for a secure and leak-free installation. The tube may feature reinforced sections for high-pressure oil flow and specialized coatings to resist corrosion.

Benefits

Using the Lubricating Oil Transfer Tube 3632828 improves lubrication efficiency, ensuring all engine components receive necessary oil for smooth operation. This enhanced lubrication protects the engine, reducing the risk of damage from friction and heat, and potentially extending the engine’s lifespan and reducing maintenance frequency.

Installation Process

Installing this part requires careful attention to detail. Preparatory steps include ensuring the engine is cool and the lubrication system is drained of old oil. Necessary tools may include wrenches, sealant, and a torque wrench. Following the manufacturer’s guidelines for torque specifications and ensuring all connections are tight and secure is crucial to prevent leaks.

Troubleshooting Common Issues

Common issues with the Lubricating Oil Transfer Tube 3632828 may include leaks, blockages, or damage. Troubleshooting involves inspecting the tube and connections for wear or damage, checking for proper installation, and ensuring all connections are secure. Solutions may range from tightening loose connections to replacing damaged sections.

Maintenance Tips

Regular maintenance of the Lubricating Oil Transfer Tube 3632828 is crucial for optimal performance. This includes periodic inspections for wear, corrosion, or leaks, and cleaning the tube and connections as part of routine engine maintenance. Replacement should be considered if significant wear or damage is detected, or as part of a scheduled maintenance program.

Cummins: A Brief Overview

Cummins Inc. is a leader in the diesel engine manufacturing industry, known for its innovation and quality. The company’s expertise in engine technology and commitment to advancing the commercial truck industry are evident in its product offerings, including the Lubricating Oil Transfer Tube 3632828. Cummins’ dedication to quality and performance ensures its components contribute significantly to the reliability and efficiency of commercial vehicles.

Cummins Engine Compatibility with Lubricating Oil Transfer Tube Part 3632828

The Cummins lubricating oil transfer tube part number 3632828 is designed to fit a range of Cummins engines, ensuring efficient oil transfer and maintaining optimal engine performance. This part is compatible with several engine models, which can be grouped based on their specifications and configurations.

K38 and K50 Series Engines

The part 3632828 is suitable for the K38 and K50 series engines. These engines are known for their robust design and reliability, often used in heavy-duty applications. The lubricating oil transfer tube ensures that oil is efficiently circulated within the engine, reducing wear and tear and enhancing longevity.

QSK38 and QSK50 Series Engines

The QSK38 and QSK50 series engines also benefit from the use of the 3632828 lubricating oil transfer tube. These engines are equipped with advanced features such as the CM2150 and CM850 control modules, which require precise oil flow for optimal operation. The part is designed to integrate seamlessly with these control modules, ensuring that the engine operates smoothly and efficiently.

- QSK38 CM2150 MCRS

- QSK38 CM850 MCRS

The MCRS (Modular Component Retrofit System) in these engines allows for easy retrofitting and maintenance, making the 3632828 part a crucial component in maintaining engine performance.

QSK50 Series Engines with CM2150 and CM2350 Control Modules

The QSK50 series engines with CM2150 and CM2350 control modules also require the 3632828 lubricating oil transfer tube for proper oil circulation. These engines are designed for high-performance applications and benefit from the precise oil flow that this part provides.

- QSK50 CM2150 K107

- QSK50 CM2150 MCRS

- QSK50 CM2350 K108

The K107 and K108 configurations in these engines are optimized for specific applications, and the 3632828 part ensures that the oil transfer system remains efficient and reliable, supporting the engine’s performance and durability.

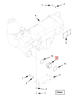

Role of Part 3632828 Lubricating Oil Transfer Tube in Engine Systems

The Part 3632828 Lubricating Oil Transfer Tube is a critical component in the efficient operation of various engine systems. Its primary function is to facilitate the smooth transfer of lubricating oil within the engine, ensuring that all moving parts receive adequate lubrication. This is particularly important in maintaining the longevity and performance of the engine.

Integration with Key Components

-

Arrangement: The Lubricating Oil Transfer Tube is strategically positioned within the engine arrangement to optimize the flow of oil. This ensures that oil is distributed evenly across all critical components, reducing friction and wear.

-

Crankcase Breather: The tube works in conjunction with the crankcase breather system. As the crankcase breather releases pressure and contaminants from the crankcase, the transfer tube ensures that fresh, clean oil is available to replace the oil that may be lost or contaminated during this process.

-

Filter: The tube is often connected to the lubricating oil filter. This connection ensures that the oil passing through the tube is clean and free from contaminants, which is vital for the proper functioning of the engine’s moving parts.

-

Lubricating Oil: The primary medium through which the transfer tube operates is the lubricating oil itself. The tube ensures a consistent supply of oil to areas such as the crankshaft, camshaft, and other critical components that require lubrication.

-

Kit, Retrofit LB and Kit, Retrofit RB: These retrofit kits often include the Lubricating Oil Transfer Tube as a key component. The tube is designed to be compatible with these kits, allowing for seamless integration into existing engine systems. This enhances the efficiency of oil transfer and improves the overall performance of the engine.

-

Lubricating Oil Filter: The tube is also connected to the lubricating oil filter, ensuring that the oil circulating within the engine is clean and free from debris. This connection is vital for maintaining the integrity of the engine’s lubrication system.

Conclusion

The Lubricating Oil Transfer Tube 3632828 plays a significant role in the efficient operation of engine systems by ensuring the smooth and consistent transfer of lubricating oil to all critical components. Its integration with other components such as the crankcase breather, filter, and retrofit kits enhances the overall performance and longevity of the engine.

-

Fischer, R., Kucukay, F., Jurgens, G., Najork, R., & Pollak, B. (2015). The Automotive Transmission Book Powertrain. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.