This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

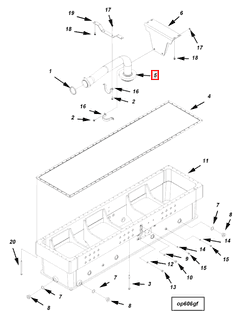

The Lubricating Oil Supply Tube, identified by part number 3641783, is a component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industry. This tube is integral to the lubrication system of heavy-duty truck engines, facilitating the delivery of oil to various critical components within the engine.

Function and Operation

The Lubricating Oil Supply Tube operates as a conduit within the engine’s lubrication system. Its primary role is to transport oil from the oil pump to the main oil gallery and subsequently to other critical components such as the crankshaft, camshaft, and valve train. By ensuring a consistent supply of oil, the tube contributes to the reduction of friction and wear between moving parts, which is vital for the engine’s efficient operation and longevity 1.

Key Features

The design and construction of the Lubricating Oil Supply Tube are tailored to meet the demanding requirements of heavy-duty engines. It is typically made from high-quality materials that offer resistance to corrosion and high temperatures. The tube features secure connection types, such as O-ring seals or threaded fittings, to ensure a leak-free operation. Additionally, its robust construction is designed to withstand the pressures and vibrations inherent in heavy-duty applications, enhancing its performance and durability 2.

Benefits

The Lubricating Oil Supply Tube offers several advantages that contribute to the overall efficiency and reliability of the engine. By ensuring a steady supply of oil to critical components, it plays a role in maintaining optimal lubrication, which in turn reduces wear and tear on engine parts. This consistent lubrication is instrumental in preserving the engine’s performance and extending its operational life. Furthermore, the tube’s design and material composition contribute to the engine’s reliability under various operating conditions 3.

Installation and Maintenance

Proper installation of the Lubricating Oil Supply Tube is crucial for its effective operation. It should be securely fitted according to the manufacturer’s guidelines to prevent leaks and ensure efficient oil flow. Regular maintenance practices, such as inspecting for signs of wear or damage and ensuring connections remain tight, are recommended to maintain optimal performance. Additionally, adhering to the manufacturer’s scheduled maintenance intervals for oil changes can help in identifying and addressing any issues related to the lubrication system 4.

Troubleshooting

Common issues associated with the Lubricating Oil Supply Tube may include leaks, blockages, or damage to the tube itself. Diagnostic procedures for identifying these problems involve visual inspections for leaks, checking oil pressure readings, and examining the tube for signs of wear or corrosion. Recommended solutions may range from tightening connections or replacing seals to, in more severe cases, replacing the tube. Addressing these issues promptly can help maintain the efficiency and reliability of the engine’s lubrication system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive and heavy-duty truck industry. Its extensive product range and commitment to excellence have made Cummins a preferred choice for professionals and enthusiasts alike, ensuring that their components, like the Lubricating Oil Supply Tube, meet the high standards required for heavy-duty applications.

Cummins Engine Part 3641783: Lubricating Oil Supply Tube

The Cummins part 3641783, known as the Lubricating Oil Supply Tube, is a critical component in the maintenance and operation of several Cummins engine models. This part is integral to the proper functioning of the engine’s lubrication system, ensuring that oil is efficiently distributed to the various moving parts, thereby reducing friction and wear.

Application in Cummins Engines

QSK60 CM500 and QSK60 CM850 MCRS

The Lubricating Oil Supply Tube (part 3641783) is designed to fit seamlessly within the QSK60 CM500 and QSK60 CM850 MCRS engines. These engines are part of Cummins’ QSK60 series, which is known for its robust performance and reliability in various industrial applications. The part’s design ensures compatibility with the specific architecture of these engines, facilitating smooth oil flow and maintaining optimal engine performance.

QSK60 CM850 MCRS

In the QSK60 CM850 MCRS engine, the Lubricating Oil Supply Tube (part 3641783) plays a pivotal role in the engine’s lubrication system. This engine variant is particularly notable for its high power output and efficiency, making it suitable for demanding applications. The part’s precision engineering ensures that it meets the stringent requirements of this high-performance engine, contributing to its longevity and reliability.

Installation and Functionality

The installation of the Lubricating Oil Supply Tube (part 3641783) in these engines is a straightforward process, designed to be integrated into the engine’s existing lubrication pathways. This part is engineered to withstand the high pressures and temperatures typical of engine operation, ensuring durability and consistent performance over time.

By ensuring a reliable supply of lubricating oil, the part 3641783 helps to maintain the integrity of the engine’s components, reducing the risk of mechanical failure and extending the engine’s operational life. Its design and material selection are critical to its function, reflecting Cummins’ commitment to quality and performance in their engine components.

Role of Part 3641783 Lubricating Oil Supply Tube in Engine Systems

The part 3641783 lubricating oil supply tube is integral to the efficient operation of engine systems, particularly in ensuring a consistent and reliable flow of oil to various engine components.

Oil Pan Integration

The oil pan serves as the reservoir for the engine’s lubrication system, storing a sufficient volume of oil to meet the engine’s demands. The lubricating oil supply tube connects directly to the oil pan, drawing oil from this reservoir. This connection ensures that the oil pan maintains adequate oil levels, facilitating the continuous circulation necessary for engine lubrication.

Oil Circulation

Once oil is drawn from the oil pan via the lubricating oil supply tube, it is transported to the oil pump. The oil pump then pressurizes the oil and distributes it throughout the engine. This pressurized oil flows through the supply tube to critical engine components, such as the crankshaft, camshaft, and valve train.

Component Lubrication

The lubricating oil supply tube plays a significant role in delivering oil to these components, reducing friction and wear. For the crankshaft, consistent oil supply ensures smooth rotation and minimizes metal-to-metal contact. Similarly, the camshaft relies on a steady oil flow to maintain proper valve operation and timing. The valve train, comprising components like lifters, rockers, and valves, also benefits from the reliable oil delivery provided by the supply tube, ensuring these parts function without excessive wear or failure.

Maintenance of Oil Pressure

The consistent flow of oil facilitated by the lubricating oil supply tube helps maintain optimal oil pressure within the engine. This pressure is vital for the effective lubrication of moving parts and the prevention of metal-to-metal contact, which can lead to increased wear and potential engine damage.

Thermal Management

In addition to lubrication, the oil circulated by the supply tube aids in thermal management. As oil flows through the engine, it absorbs heat from various components, carrying it back to the oil pan where it can be dissipated. This process helps regulate engine temperature, contributing to overall engine efficiency and longevity.

Conclusion

In summary, the part 3641783 lubricating oil supply tube is a key component in the engine’s lubrication system, ensuring that oil is efficiently drawn from the oil pan and distributed to essential engine parts. This consistent oil flow is fundamental to the lubrication, cooling, and overall performance of the engine.

-

Viskup, Richard. Diesel and Gasoline Engines. IntechOpen, 2020.

↩ -

Wright, Gus. Fundamentals of Medium-Heavy Duty Diesel Engines. Jones & Bartlett Learning, 2015.

↩ -

Hilgers, Michael. Transmissions and Drivetrain Design. Springer Vieweg, 2022.

↩ -

Rajamani, Rajesh. Vehicle Dynamics and Control. Springer, 2005.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.