This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

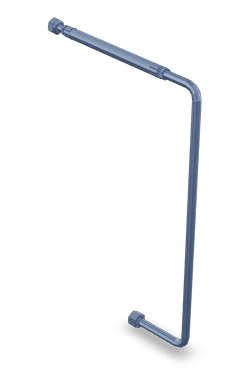

The Lubricating Oil Supply Tube 3650558, manufactured by Cummins, is a critical component in the heavy-duty truck industry. This tube is essential for the engine lubrication system, ensuring the delivery of oil to various engine components. Proper lubrication is key to the efficient operation and longevity of heavy-duty truck engines, reducing friction, wear, and heat 1.

Function and Operation

The Lubricating Oil Supply Tube operates as a conduit within the engine’s lubrication system. Its primary function is to transport oil from the oil pump to different engine parts that require lubrication, including bearings, pistons, and other moving components. This consistent oil flow is vital for maintaining optimal lubrication levels, which is essential for engine performance and durability 2.

Key Features

This Cummins part is designed with several key features to enhance its performance. It is constructed from high-quality materials resistant to corrosion and wear, ensuring durability under the demanding conditions of heavy-duty truck engines. The tube’s design includes precise fittings and connections for a secure and leak-free installation. It may also feature reinforced sections to withstand high pressure and temperature variations within the engine 3.

Benefits of Proper Lubrication

Effective lubrication significantly reduces friction between moving parts, minimizing wear and tear. It also aids in dissipating heat, preventing overheating of engine components. The Lubricating Oil Supply Tube 3650558 ensures a reliable and consistent supply of oil to all lubricated parts, supporting the engine’s efficiency and longevity.

Installation and Compatibility

Proper installation of the Lubricating Oil Supply Tube 3650558 is crucial for its effective operation. It is designed to be compatible with a range of Cummins engine models, facilitating easy integration into the engine’s lubrication system. Following manufacturer guidelines during installation ensures a secure and efficient connection. Compatibility with other components should be verified for seamless operation within the engine system.

Maintenance and Troubleshooting

Regular maintenance of the Lubricating Oil Supply Tube 3650558 is recommended to ensure its optimal function. This includes periodic checks for leaks, corrosion, or wear. In case of issues such as oil leaks or inconsistent oil flow, troubleshooting steps may involve inspecting the tube for damage, ensuring all connections are secure, and verifying the oil pump’s operation. Timely maintenance and addressing issues promptly can prevent more significant problems and ensure the engine’s continued efficient operation.

Cummins Corporation

Cummins Corporation is renowned in the heavy-duty truck industry for its extensive range of engine components and systems. With a history of innovation and quality, Cummins has established a strong reputation for manufacturing reliable and high-performance engine parts. The company’s commitment to quality is evident in its product line, including the Lubricating Oil Supply Tube 3650558, designed to meet the rigorous demands of heavy-duty applications.

Lubricating Oil Supply Tube (Part 3650558) in Cummins Engines

The Cummins part number 3650558, known as the Lubricating Oil Supply Tube, is a critical component in the maintenance and operation of several Cummins engine models. This part ensures the proper flow of lubricating oil throughout the engine, which is essential for reducing friction, preventing wear, and maintaining engine efficiency.

QSK60 and CM850 Engines

In the QSK60 and CM850 engines, the Lubricating Oil Supply Tube (3650558) plays a pivotal role in the engine’s lubrication system. These engines, known for their robust performance and reliability, require precise oil distribution to function optimally. The part is engineered to fit seamlessly within the engine’s architecture, ensuring that oil is delivered to all necessary components without interruption. This is particularly important in high-stress environments where the engines are subjected to heavy loads and varying operational conditions.

MCRS Engines

The MCRS engines also benefit from the use of the Lubricating Oil Supply Tube (3650558). These engines are designed for versatility and efficiency, often used in a variety of applications ranging from marine to industrial use. The part’s design allows for easy integration into the engine’s oil system, providing a reliable pathway for oil to reach critical engine parts. This ensures that the MCRS engines can maintain their performance and longevity, even under demanding operational scenarios.

Common Features Across Engines

While the specific applications of the Lubricating Oil Supply Tube (3650558) may vary across different engine models, its fundamental purpose remains consistent. The part is crafted to withstand the rigors of engine operation, including high temperatures and pressures. Its design facilitates smooth oil flow, which is crucial for the overall health and efficiency of the engine. The tube’s material and construction are chosen to ensure durability and resistance to wear, making it a reliable component in Cummins’ engine lineup.

By integrating the Lubricating Oil Supply Tube (3650558) into the QSK60, CM850, and MCRS engines, Cummins ensures that these engines can operate at peak performance, with reduced risk of mechanical failure and extended service life.

Role of Part 3650558 Lubricating Oil Supply Tube in Engine Systems

The Lubricating Oil Supply Tube 3650558 is an integral component in the efficient operation of engine lubricating systems. This tube facilitates the continuous flow of lubricating oil from the oil reservoir to various engine components that require lubrication.

In the context of a primer system, the Lubricating Oil Supply Tube ensures that the primer, which is often used to facilitate easier engine starting by lubricating the cylinder walls and piston rings before ignition, receives a consistent supply of oil. This helps in reducing friction and wear during the initial cranking phase.

Within the engine lubricating system, the tube plays a significant role by delivering oil to critical engine components such as the crankshaft, camshaft, bearings, and valve train. Proper lubrication of these parts is essential for minimizing friction, dissipating heat, and preventing metal-to-metal contact that could lead to premature wear or failure.

The tube also interacts with the oil filter, ensuring that clean, filtered oil is circulated throughout the engine. This is vital for maintaining the integrity of engine components and prolonging the engine’s operational life.

Conclusion

In summary, the Lubricating Oil Supply Tube 3650558 is a key element in maintaining the health and performance of engine systems by ensuring a steady and reliable supply of lubricating oil to all necessary components. Its role in facilitating efficient lubrication, reducing friction, and preventing wear is crucial for the longevity and optimal operation of heavy-duty truck engines.

-

Giles, T. (2019). Automotive Engines Diagnosis Repair and Rebuilding. Cengage Learning.

↩ -

Pulkrabek, W. W. (2014). Engineering Fundamentals of the Internal Combustion Engine. Pearson Education.

↩ -

Awari, G.K., Kumbhar, V.S., & Tirpude, R.B. (2011). Automotive Systems Principles and Practice. CRC Press.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.