This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

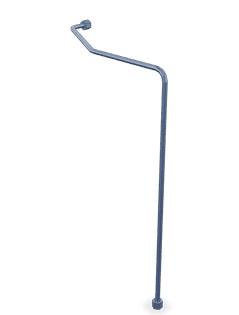

The Lubricating Oil Transfer Tube (3651033) by Cummins is a component designed to facilitate the efficient transfer of lubricating oil within the lubrication system of commercial trucks. Its role is significant in maintaining the proper functioning and longevity of the engine by ensuring that oil is consistently delivered to critical engine components 3.

Function and Operation

The Lubricating Oil Transfer Tube operates as a conduit within the truck’s lubrication system. It is responsible for transferring oil from the oil pan to various engine components that require lubrication, such as the crankshaft, camshaft, and bearings. This transfer is vital for reducing friction between moving parts, which helps in maintaining operational efficiency and preventing premature wear 1.

Key Features

The Lubricating Oil Transfer Tube is constructed from high-quality materials that are resistant to the harsh conditions within an engine environment. Its design includes precise engineering to ensure a secure fit and optimal oil flow. Unique characteristics such as reinforced sections and smooth interior surfaces enhance its performance and durability, contributing to the overall reliability of the lubrication system 2.

Benefits

The use of the Lubricating Oil Transfer Tube offers several benefits. It contributes to improved lubrication efficiency by ensuring a consistent and adequate supply of oil to engine components. This results in reduced friction and wear, which in turn supports enhanced engine performance and longevity. The tube’s design and material properties also play a role in maintaining the integrity of the lubrication system under varying operating conditions 3.

Installation and Maintenance

Proper installation of the Lubricating Oil Transfer Tube involves ensuring that it is correctly aligned and securely fitted within the lubrication system. Preparations may include cleaning the installation area and inspecting the tube for any damage prior to installation. Maintenance tips include regular inspection for signs of wear or damage, checking for leaks, and adhering to recommended replacement intervals to ensure optimal performance and longevity of the tube 1.

Troubleshooting

Common issues with the Lubricating Oil Transfer Tube may include leaks, blockages, or signs of wear. Troubleshooting steps involve identifying the source of the problem, which may require disassembling parts of the lubrication system for a thorough inspection. Addressing leaks may involve tightening connections or replacing damaged sections, while ensuring proper alignment and fitment can resolve issues related to blockages or inefficient oil transfer 2.

Cummins Overview

Cummins Inc. is a well-established manufacturer in the automotive industry, known for its commitment to producing high-quality components for commercial vehicles. With a rich history of innovation and a strong reputation for reliability, Cummins continues to be a trusted name in the manufacturing of engine parts and systems, including the Lubricating Oil Transfer Tube 3.

Integration with Plumbing Systems

In the context of engine plumbing, the Lubricating Oil Transfer Tube plays a significant role. It connects the oil reservoir to critical engine components, such as the crankshaft, camshaft, and valve train. This ensures a consistent supply of oil, which is essential for reducing friction and wear. The tube is designed to handle the pressure and flow rates specific to the engine’s requirements, maintaining a stable oil circulation system 1.

Support for Turbocharger Oil Systems

For engines equipped with turbochargers, the Lubricating Oil Transfer Tube is equally important. Turbochargers require a dedicated oil supply to lubricate their bearings and maintain operational efficiency. The transfer tube ensures that oil is delivered to the turbocharger at the necessary pressure and flow rate. This is vital for the turbocharger’s performance, as inadequate lubrication can lead to premature wear and failure. The tube’s design also accounts for the thermal expansion and contraction that occur due to the high temperatures associated with turbocharger operation 2.

Enhanced Engine Reliability

By ensuring a reliable oil supply to both the engine’s internal components and external systems like the turbocharger, the Lubricating Oil Transfer Tube contributes to the overall reliability of the engine. It helps in maintaining the correct oil levels and pressure, which are essential for the engine’s smooth operation under various conditions 3.

Conclusion

Understanding the role of part 3651033 in these systems highlights its importance in maintaining engine health and performance. Proper installation and maintenance of this component are key to ensuring the engine operates efficiently and reliably.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.