This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

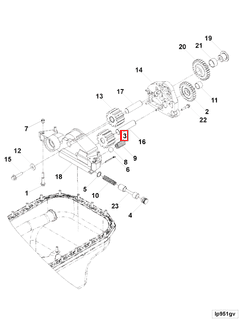

The Lubricating Oil Pumping Gear 3680690 is a component designed by Cummins to facilitate the efficient distribution of lubricating oil within commercial truck engines. This part is integral to maintaining optimal engine performance and longevity by ensuring that all moving parts receive adequate lubrication 1.

Basic Concepts of Lubricating Oil Pumping Gear

Lubricating oil pumping gears are fundamental components within the lubrication system of an engine. Their primary function is to circulate oil from the oil pan to various engine components, including bearings, pistons, and camshafts. By maintaining a consistent flow of oil, these gears help reduce friction between moving parts, dissipate heat, and remove contaminants, thereby contributing to engine performance and durability 2.

Purpose and Role in Truck Operation

The Lubricating Oil Pumping Gear 3680690 plays a specific role in the operation of a truck by facilitating the distribution of lubricating oil throughout the engine. It works in conjunction with the oil pump to ensure that oil is delivered under pressure to critical engine components. This consistent lubrication is vital for minimizing wear and tear, enhancing engine efficiency, and prolonging the engine’s operational life 3.

Key Features

The Lubricating Oil Pumping Gear 3680690 is characterized by several key features that enhance its performance and reliability. Its design incorporates high-quality materials that are resistant to wear and corrosion, ensuring durability under demanding conditions. Additionally, the gear is engineered to operate efficiently within the specified parameters of Cummins engines, providing reliable lubrication even under high-stress scenarios 4.

Benefits

The advantages provided by the Lubricating Oil Pumping Gear 3680690 include improved engine lubrication, which leads to reduced friction between moving parts. This reduction in friction not only enhances engine performance but also contributes to increased durability. Furthermore, efficient lubrication can result in potential fuel efficiency gains, as less energy is required to overcome friction within the engine 5.

Troubleshooting and Maintenance

Common issues that may arise with the Lubricating Oil Pumping Gear 3680690 include oil leaks, unusual noises, or a decrease in oil pressure. To address these issues, it is recommended to perform regular inspections and maintenance checks. This includes verifying the integrity of oil seals, ensuring proper gear alignment, and monitoring oil levels and quality. Adhering to manufacturer-recommended maintenance schedules can help prevent premature wear and ensure optimal performance 6.

Integration with Cummins Engines

The Lubricating Oil Pumping Gear 3680690 is designed to integrate seamlessly with Cummins engines. It is engineered to meet the specific requirements and tolerances of Cummins engine designs, ensuring compatibility and efficient operation. Installation procedures are straightforward, provided that they are carried out according to manufacturer guidelines to maintain the integrity of the lubrication system 7.

Compatibility of Lubricating Oil Pumping Gear (Part 3680690) with Cummins Engines

The Cummins Lubricating Oil Pumping Gear, identified by part number 3680690, is designed to fit a variety of Cummins engines. This part is integral to the proper functioning of the engine’s lubrication system, ensuring that oil is circulated efficiently to reduce friction and wear.

ISX Series Engines

- ISX CM570

- ISX CM870

- ISX CM871

- ISX15 CM2250

- ISX15 CM2250 SN

- ISX15 CM2350 X101

The ISX series engines, including the ISX CM570, ISX CM870, ISX CM871, ISX15 CM2250, ISX15 CM2250 SN, and ISX15 CM2350 X101, are compatible with the 3680690 oil pumping gear. These engines are known for their robust performance and are commonly used in heavy-duty applications.

QSX Series Engines

- QSX15 CM2250

- QSX15 CM2250 ECF

- QSX15 CM2350 X105

The QSX15 series engines, specifically the QSX15 CM2250, QSX15 CM2250 ECF, and QSX15 CM2350 X105, also support the use of the 3680690 oil pumping gear. These engines are designed for applications that require high power and efficiency.

X15 Series Engines

- X15 CM2350 X116B

- X15 CM2350 X123B

- X15 CM2450 X134B

The X15 series engines, including the X15 CM2350 X116B, X15 CM2350 X123B, and X15 CM2450 X134B, are compatible with the 3680690 oil pumping gear. These engines are engineered for durability and reliability in demanding environments.

Role of Part 3680690 Lubricating Oil Pumping Gear in Engine Systems

The lubricating oil pumping gear, identified as part 3680690, is integral to the efficient operation of various engine systems. This component is specifically designed to work in conjunction with the lubricating oil pump, ensuring that oil is circulated effectively throughout the engine.

When integrated into a lubricating pump kit, the lubricating oil pumping gear enhances the pump’s ability to maintain consistent oil pressure, which is essential for reducing friction between moving parts. This results in smoother operation and prolonged engine life.

In the context of an overhaul kit, the lubricating oil pumping gear plays a significant role in restoring the pump’s functionality. By replacing worn-out gears, it ensures that the pump can deliver oil with the necessary pressure and flow rate, crucial for the engine’s performance post-overhaul.

The gear’s interaction with the pump itself is seamless, as it is engineered to fit precisely within the pump’s housing. This fitment allows for optimal meshing with other internal components, facilitating efficient oil circulation.

Overall, the lubricating oil pumping gear is a key element in maintaining the health and efficiency of the engine’s lubricating system, directly influencing the engine’s reliability and performance.

Conclusion

The Lubricating Oil Pumping Gear 3680690 by Cummins is a critical component in the lubrication system of commercial truck engines. Its role in ensuring efficient oil circulation contributes significantly to engine performance, durability, and fuel efficiency. Regular maintenance and proper integration with Cummins engines are essential for maximizing the benefits of this part.

-

Martyr, A.J. (2007). Engine Testing: Theory and Practice: Third Edition. SAE International.

↩ -

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ -

Quigley, J.M. (2023). SAE International’s Dictionary of Testing, Verification and Validation. SAE International.

↩ -

Kasab, J., & Strzelec, A. (2020). Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International.

↩ -

Martyr, A.J. (2007). Engine Testing: Theory and Practice: Third Edition. SAE International.

↩ -

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ -

Quigley, J.M. (2023). SAE International’s Dictionary of Testing, Verification and Validation. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.