3689895

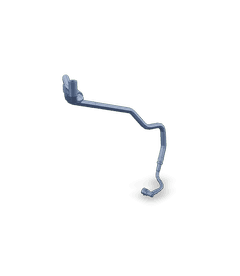

Lubricating Oil Drain Tube

Cummins®

IN STOCK

2 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Lubricating Oil Drain Tube 3689895 is a component designed for use in heavy-duty trucks, specifically engineered to facilitate the efficient drainage of lubricating oil from the engine. This part is integral to maintaining the engine’s health by ensuring that old oil is effectively removed during oil changes, allowing for the introduction of fresh lubricant. Cummins Inc., a well-established manufacturer in the automotive and heavy-duty truck industry, produces this drain tube. Known for its commitment to quality and innovation, Cummins provides parts that are designed to meet the rigorous demands of heavy-duty applications 1.

Function and Operation

The Lubricating Oil Drain Tube 3689895 operates as a conduit within the engine system, designed to channel used oil away from the engine during the oil change process. When the drain plug is removed, oil flows through the tube, guided by its design to ensure a smooth and complete drainage. This process is vital for maintaining the engine’s efficiency and longevity, as it allows for the removal of contaminants and degraded oil that can accumulate over time 2.

Key Features

The Lubricating Oil Drain Tube 3689895 is constructed from durable materials, ensuring it can withstand the high temperatures and pressures within the engine compartment. Its design includes features such as a precise fit to the engine’s drain plug, which aids in secure attachment and efficient oil flow. Additionally, the tube may incorporate anti-kink properties to prevent obstructions during the drainage process, enhancing its performance and reliability.

Benefits of Using Lubricating Oil Drain Tube 3689895

Incorporating the Lubricating Oil Drain Tube 3689895 into truck maintenance routines offers several advantages. It contributes to improved engine longevity by ensuring that oil changes are conducted efficiently, removing all used oil and contaminants. This part also simplifies the oil change process, reducing the time and effort required for maintenance. Furthermore, by facilitating complete oil drainage, it helps maintain the quality of the lubricant within the engine, supporting optimal performance and protection against wear 3.

Installation and Usage Guidelines

Proper installation of the Lubricating Oil Drain Tube involves securing it to the engine’s drain plug, ensuring a tight fit to prevent leaks. It is important to follow manufacturer guidelines for installation to ensure optimal performance. Usage best practices include regularly inspecting the tube for signs of wear or damage and ensuring it is correctly positioned during oil changes to facilitate efficient drainage.

Troubleshooting Common Issues

Common issues with Lubricating Oil Drain Tubes may include leaks, kinks, or blockages. Identifying these problems early can prevent more significant engine issues. Signs of wear or malfunction may include difficulty in draining oil or visible damage to the tube. Addressing these issues promptly, through repair or replacement, is important for maintaining engine health.

Maintenance Tips

Regular maintenance checks of the Lubricating Oil Drain Tube 3689895 are recommended to prolong its life and ensure efficient operation. This includes inspecting the tube for signs of wear, damage, or kinks before each oil change. If the tube shows significant wear or if oil changes become less efficient, considering replacement is advisable to maintain the engine’s performance and protect against potential damage.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the automotive and heavy-duty truck industry. Its product range includes engines, powertrains, and related components, all designed to meet the demanding requirements of various applications.

Application in Cummins Engines

The Cummins part 3689895, a Lubricating Oil Drain Tube, is designed to fit seamlessly within the engine architecture of the QSX15 CM2250 ECF and QSX15 CM2350 X105 models. These engines are known for their robust performance and reliability, often used in heavy-duty applications such as commercial trucks and industrial machinery. The lubricating oil drain tube plays a vital role in these engines by ensuring that the oil is properly drained, which is essential for maintaining optimal engine performance and longevity 4.

Importance of the Lubricating Oil Drain Tube

The lubricating oil drain tube is integral to the engine’s oil management system. It ensures that the used oil is effectively removed from the engine’s sump, preventing contamination and reducing the risk of engine failure. This part is designed to withstand the high temperatures and pressures found within the engine, making it a durable and reliable component.

Installation and Maintenance

Proper installation of the lubricating oil drain tube is crucial to ensure that the engine operates efficiently. Technicians should follow the manufacturer’s guidelines for installation, ensuring that the tube is securely fastened and free from leaks. Regular maintenance checks should be performed to inspect the condition of the drain tube and replace it if any signs of wear or damage are detected.

Compatibility and Interchangeability

The part 3689895 is designed to be compatible with the specified Cummins engines, ensuring a precise fit and function. It is important to verify the part number and specifications when purchasing a replacement to ensure compatibility with the engine model in use. This part is not interchangeable with other engine models unless explicitly stated by Cummins.

Role of Part 3689895 Lubricating Oil Drain Tube in Engine Systems

The lubricating oil drain tube, identified as part 3689895, is an essential component in the arrangement of various engine systems, ensuring the efficient and reliable operation of the engine.

Integration with the Crankcase

The crankcase is a fundamental part of the engine, housing the crankshaft and connecting rods. The lubricating oil drain tube plays a significant role in maintaining the integrity of the crankcase by facilitating the removal of used oil. This process is vital for preventing the buildup of contaminants and sludge, which can adversely affect the performance and longevity of the engine components housed within the crankcase.

Interaction with the Crankcase Breather System

The crankcase breather system is designed to release pressure that builds up inside the crankcase due to the pistons’ movement. The lubricating oil drain tube works in conjunction with this system by ensuring that any oil that may be carried over with the released gases is efficiently drained away. This interaction helps maintain a clean breathing environment within the crankcase, enhancing the overall efficiency of the breather system.

Contribution to Overall Engine Health

By effectively draining used oil, the lubricating oil drain tube contributes to the overall health of the engine. Regular oil changes, facilitated by this component, help in removing impurities and maintaining the lubricating properties of the oil. This, in turn, reduces wear on engine parts, ensures smooth operation, and prolongs the engine’s service life.

Conclusion

In summary, the Lubricating Oil Drain Tube 3689895 is integral to the proper functioning of the crankcase and breather systems, playing a key role in maintaining engine efficiency and durability. Regular maintenance and proper installation of this part are crucial for ensuring the longevity and performance of Cummins engines.

-

Giancarlo Genta and Lorenzo Morello, The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition, Springer, 2019.

↩ -

Thorsten Boger, Willard Cutler, Reducing Particulate Emissions in Gasoline Engines, SAE International, 2018.

↩ -

Douglas R Carroll, Energy Efficiency of Vehicles, SAE International, 2020.

↩ -

Cummins Inc., Operation and Maintenance Manual for QSK60 CM2350 K121, Bulletin Number 4388646.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.