This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

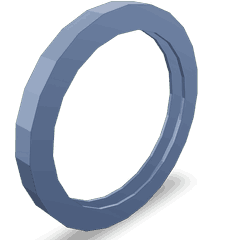

The Cummins 3693459 Oil Seal is a component designed for use in commercial trucks. It ensures that lubricants remain within the system and contaminants are kept out, contributing to the overall efficiency and longevity of the truck’s engine and other mechanical components 1.

Basic Concepts of Oil Seals

An oil seal, also known as a rotary shaft seal, is a mechanical device used to prevent the leakage of lubricants from rotating shafts while also blocking the ingress of external contaminants. It operates by maintaining a tight fit around the shaft, allowing it to rotate freely while keeping the lubricant contained within the system 2.

Purpose of the Cummins 3693459 Oil Seal

This Cummins part plays a role in the operation of a truck by maintaining the integrity of the lubrication system. It ensures that lubricants are kept within the system, providing necessary friction reduction and cooling for moving parts. Additionally, it prevents dirt, dust, and other contaminants from entering the system, which could lead to wear and damage of critical components 3.

Key Features

The Cummins 3693459 Oil Seal is characterized by its specific design and material properties that enhance its performance and durability. It is constructed from high-quality materials that offer resistance to wear and chemical degradation. The seal’s design allows it to accommodate slight misalignments and shaft deflections, ensuring a consistent seal even under dynamic operating conditions.

Benefits

The use of this part offers several advantages. It contributes to improved engine efficiency by maintaining proper lubrication, which reduces friction and heat. This seal also extends the life of engine components by preventing contaminant ingress, and it reduces maintenance requirements by minimizing the need for frequent lubricant top-ups or replacements.

Installation Considerations

Proper installation of the Cummins 3693459 Oil Seal is important for ensuring optimal performance and longevity. It should be installed with the correct orientation and without damage to the sealing lips. The mating surfaces must be clean and free of burrs or imperfections to ensure a proper seal. Following manufacturer guidelines during installation will help achieve the best results.

Troubleshooting Common Issues

Typical problems associated with oil seals include leaks and wear. These issues can often be diagnosed through visual inspection and by monitoring lubricant levels. Recommended solutions may involve replacing the seal or addressing underlying issues such as misalignment or contamination within the system.

Maintenance Tips

Routine checks and maintenance practices can help prolong the life of the Cummins 3693459 Oil Seal. Regular inspections for signs of wear or damage, keeping the area around the seal clean, and ensuring that the lubrication system is properly maintained are all practices that contribute to the continued reliable operation of the seal.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and reliability in the commercial truck industry. The company’s commitment to innovation and customer satisfaction has made it a preferred choice for commercial vehicle operators worldwide.

Compatibility of Oil Seal Part 3693459 with Cummins Engines

The Oil Seal part 3693459, manufactured by Cummins, is designed to fit a variety of their engine models. This seal is crucial for maintaining the integrity of the engine by preventing oil leaks, ensuring that the engine operates smoothly and efficiently.

ISG11 CM2880 G108 and ISG12 CM2880 G107

These engines, both part of the ISG series, utilize the Oil Seal part 3693459 to maintain the sealing around the crankshaft. This ensures that the oil remains within the engine, protecting the crankshaft and other internal components from wear and tear.

ISG12 G CMOH6.0 G111

The ISG12 G CMOH6.0 G111 engine also benefits from the Oil Seal part 3693459. This seal is integral in maintaining the oil barrier around the crankshaft, which is essential for the engine’s longevity and performance.

QSG12 CM2880 G112 and QSG12/X12 CM2350 G110

Both the QSG12 CM2880 G112 and QSG12/X12 CM2350 G110 engines incorporate the Oil Seal part 3693459 to ensure that the crankshaft is properly sealed. This prevents oil from leaking out, which could lead to engine damage and decreased efficiency.

X11 CM2670 X126B and X12 CM2350 X119B

The X11 CM2670 X126B and X12 CM2350 X119B engines use the Oil Seal part 3693459 to maintain the seal around the crankshaft. This is vital for the engines’ operation, as it helps to keep the oil contained and the engine running smoothly.

X12 CM2670 X121B and X12N CMMDG1 X143B

These engines, the X12 CM2670 X121B and X12N CMMDG1 X143B, also rely on the Oil Seal part 3693459 for sealing the crankshaft. This ensures that the engine’s oil remains where it is needed, preventing leaks and maintaining optimal engine performance.

X13 CM2670 X122B

The X13 CM2670 X122B engine utilizes the Oil Seal part 3693459 to maintain the seal around the crankshaft. This is crucial for preventing oil leaks and ensuring that the engine operates efficiently.

Role of Part 3693459 Oil Seal in Engine Systems

The part 3693459 Oil Seal is a component in maintaining the integrity and efficiency of various engine systems. Its primary function is to prevent the leakage of lubricating oil, ensuring that the oil remains within the designated pathways and components where it is needed most.

Interaction with the Lower Engine Gasket Kit

Within the lower engine gasket kit, the oil seal plays a significant role in sealing the interfaces between moving and stationary parts. This ensures that lubricating oil does not escape from the crankcase or other lower engine components. Proper sealing is vital for maintaining oil pressure and ensuring that all moving parts receive adequate lubrication, which is fundamental for reducing friction and wear.

Contribution to Pump Efficiency

In the context of the pump, the oil seal is positioned to prevent oil from leaking out of the pump housing. This is particularly important in systems where the pump is responsible for circulating lubricating oil throughout the engine. By maintaining a tight seal, the oil seal ensures that the pump can operate efficiently, delivering the necessary volume of oil to critical components without loss.

Ensuring Lubricating Oil Effectiveness

The effectiveness of lubricating oil is greatly enhanced by the presence of a reliable oil seal. By preventing oil leakage, the seal helps maintain the correct oil level within the engine. This is essential for the oil to perform its primary functions: reducing friction between moving parts, dissipating heat, and carrying away contaminants. A well-sealed system ensures that the lubricating oil can consistently provide these benefits, leading to prolonged engine life and optimal performance.

Conclusion

The Cummins 3693459 Oil Seal is a critical component in the maintenance and efficiency of commercial truck engines. By ensuring that lubricants remain within the system and contaminants are kept out, this part contributes to the overall performance and longevity of the engine. Proper installation, regular maintenance, and timely replacement when necessary are key to maximizing the benefits of this essential component.

-

The Motor Vehicle, TK Garrett, K Newton, W Steeds, Reed Educational and Professional Publishing Ltd, 2001

↩ -

Fundamentals of Motor Vehicle Technology Book 1 6th Edition, Alma Hillier, Oxford University Press, 2014

↩ -

Motor Vehicle Mechanics Textbook, Fifth Edition, F. K. Sully, Heinemann Professional Publishing, 1998

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.