3694064

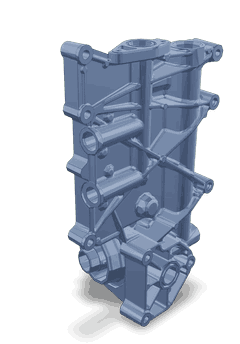

Oil Filter Cooler Housing

Cummins®

IN STOCK

4 are currently available

Ships within 1 business day

This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Oil Filter Cooler Housing (Part #3694064) by Cummins is designed to enhance the efficiency and reliability of heavy-duty trucks. This Cummins part ensures optimal performance of the truck’s lubrication system by regulating oil temperature, which is vital for the longevity and efficiency of the engine 1.

Basic Concepts of Oil Filter Cooler Housing

Oil filter cooler housings are integral to the lubrication system of heavy-duty trucks. Their primary function is to regulate the temperature of the engine oil by dissipating excess heat. This is achieved through a heat exchange process where the hot oil passes through the housing and is cooled before being recirculated back into the engine. Maintaining optimal oil temperature ensures the oil retains its viscosity and lubricating properties, which are necessary for reducing friction and wear on engine components 2.

Purpose and Role in Truck Operation

The Oil Filter Cooler Housing serves a pivotal role in the operation of a truck by ensuring that the engine oil remains at an optimal temperature. This housing allows the oil to be cooled as it passes through, preventing overheating which can lead to a breakdown of the oil’s molecular structure and a subsequent loss of its lubricating qualities. By maintaining the oil at the correct temperature, the housing contributes to enhanced engine performance and longevity, ensuring that the engine operates smoothly and efficiently over time 3.

Key Features

The Cummins Oil Filter Cooler Housing is designed with several key features that enhance its performance. It is constructed from high-quality materials that are resistant to corrosion and wear, ensuring durability in harsh operating conditions. The housing is engineered to maximize heat dissipation, featuring a design that allows for efficient cooling of the oil. Additionally, it is compatible with a variety of truck models, making it a versatile component for fleet management. The housing also includes precise fittings and connections that ensure a secure and leak-free installation.

Benefits

The benefits of the Oil Filter Cooler Housing are manifold. By effectively cooling the engine oil, it helps in maintaining the oil’s viscosity, which is crucial for reducing friction and wear on engine components. This leads to improved engine efficiency and extended oil life, reducing the frequency of oil changes and maintenance costs. Furthermore, the housing contributes to the overall performance of the truck by ensuring that the engine operates within its optimal temperature range, thereby enhancing reliability and longevity.

Installation Process

Installing the Oil Filter Cooler Housing requires careful attention to detail to ensure optimal performance. The process involves disconnecting the old housing, if present, and cleaning the mounting area. The new housing should be aligned with the fittings and secured in place using the provided hardware. It is important to ensure that all connections are tight and that there are no leaks. After installation, the system should be tested to confirm that the oil is flowing correctly and that the cooling function is operating as intended.

Maintenance and Troubleshooting

Regular maintenance of the Oil Filter Cooler Housing is important to ensure its continued efficient operation. This includes periodic inspection for signs of wear, corrosion, or leaks. Common issues to watch for include blockages in the cooling passages or loose connections. If any problems are detected, they should be addressed promptly to prevent further damage. Troubleshooting steps may involve cleaning the housing, tightening connections, or, in more severe cases, replacing the housing.

Cummins Overview

Cummins is a renowned name in the automotive industry, known for its high-quality components and innovative solutions. With a rich history of producing reliable and efficient engines and parts, Cummins has established a strong reputation for excellence. The company is committed to advancing technology in the automotive sector, ensuring that its products meet the demanding requirements of heavy-duty applications. Cummins’ dedication to quality and performance is evident in every component it manufactures, including the Oil Filter Cooler Housing.

Compatibility of Cummins Oil Filter Cooler Housing Part 3694064

The Cummins Oil Filter Cooler Housing part number 3694064 is designed to fit seamlessly with several engine models, ensuring optimal performance and longevity. This part is crucial for maintaining the integrity of the engine’s oil system by effectively cooling the oil filter and preventing overheating.

Compatible Engines

X12 CM2350

The X12 CM2350 engine benefits from the installation of the Oil Filter Cooler Housing part 3694064. This component is engineered to integrate smoothly with the X12 CM2350, enhancing the engine’s cooling efficiency and ensuring that the oil remains at the optimal temperature for peak performance.

X119B

Similarly, the X119B engine is another model that is compatible with the Oil Filter Cooler Housing part 3694064. This part is designed to fit precisely within the engine’s architecture, providing essential cooling support to the oil filter and contributing to the overall reliability and efficiency of the engine.

Grouping of Compatible Engines

The Oil Filter Cooler Housing part 3694064 is designed to fit a range of Cummins engines, including the X12 CM2350 and X119B. These engines, while distinct in their specifications and applications, share a common need for effective oil cooling. The part’s design ensures it can be installed with ease and precision, providing a reliable solution for maintaining the engine’s oil system integrity.

Role of Part 3694064 Oil Filter Cooler Housing in Engine Systems

In the orchestration of engine systems, the Oil Filter Cooler Housing assumes a significant role by integrating with several key components to ensure optimal engine performance and longevity.

This housing is designed to work in conjunction with the cooler, specifically the engine oil cooler. The oil cooler’s function is to regulate the temperature of the engine oil, preventing it from reaching temperatures that could lead to degradation or loss of viscosity. The Oil Filter Cooler Housing facilitates this process by providing a structured pathway for the oil to flow from the cooler to the lubricating oil filter head.

The lubricating oil filter head is responsible for filtering out contaminants from the engine oil, ensuring that only clean oil circulates through the engine’s moving parts. The Oil Filter Cooler Housing not only directs the cooled oil to the filter head but also helps in maintaining a consistent flow, which is essential for the filter’s efficiency.

Moreover, the housing plays a part in the overall engine oil system by ensuring that the oil, after being cooled and filtered, is efficiently distributed back into the engine. This consistent and regulated flow of oil is vital for reducing friction, wearing down of parts, and ultimately, enhancing the engine’s operational efficiency and lifespan.

Conclusion

In summary, the Oil Filter Cooler Housing part 3694064 is an integral component that enhances the functionality of the cooler, engine oil cooler, and lubricating oil filter head, contributing to a well-maintained and efficiently operating engine system. Its role in maintaining optimal oil temperature and ensuring the efficient operation of the lubrication system underscores its importance in the overall performance and longevity of heavy-duty trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.