This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3759619 Oil Slinger is a component designed to enhance the lubrication system in heavy-duty trucks. Its purpose is to ensure that engine parts receive adequate lubrication, which is vital for the smooth operation and longevity of the engine. By facilitating the distribution of oil to moving components, the oil slinger contributes to the overall efficiency and reliability of the engine.

Basic Concepts of an Oil Slinger

An oil slinger is a device within an engine that aids in the distribution of lubricant. It operates by spinning with the crankshaft or other rotating components, flinging oil outward to coat nearby parts. This mechanism is important for maintaining a consistent layer of lubrication on engine components, which reduces friction and wear 1. Effective lubrication is key to preserving engine performance and extending the lifespan of mechanical parts.

Purpose of the Cummins 3759619 Oil Slinger

The Cummins 3759619 Oil Slinger plays a specific role in the engine’s lubrication system by ensuring that oil is evenly distributed to critical moving parts. It helps in maintaining a film of oil on components such as bearings and journals, which are subject to high levels of stress and friction. This consistent lubrication is important for reducing wear and tear, enhancing engine efficiency, and supporting reliable operation under demanding conditions.

Key Features

The Cummins 3759619 Oil Slinger is characterized by its robust design and the materials used in its construction. It is typically made from durable metals that can withstand the high temperatures and pressures within an engine. The design of the oil slinger includes features that maximize its effectiveness in distributing oil, such as specific shapes and ridges that enhance the flinging action. These characteristics contribute to its performance and durability in heavy-duty applications.

Benefits of Using the Cummins 3759619 Oil Slinger

Incorporating the Cummins 3759619 Oil Slinger into an engine’s design offers several advantages. It contributes to improved engine performance by ensuring that all moving parts are properly lubricated. This reduces friction and wear on components, leading to enhanced reliability and potentially extending the engine’s operational life. Additionally, effective lubrication can contribute to better fuel efficiency, as less energy is lost to friction within the engine 2.

Installation and Compatibility

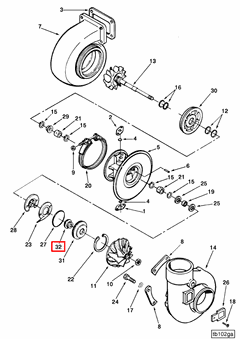

Proper installation of the Cummins 3759619 Oil Slinger is important for ensuring its effectiveness. It should be installed according to the manufacturer’s guidelines to ensure it functions correctly within the engine. Compatibility with specific engine models is a consideration, and it is important to verify that the oil slinger is suitable for the intended application to achieve optimal performance and reliability.

Maintenance and Troubleshooting

Maintaining the Cummins 3759619 Oil Slinger involves regular inspection and cleaning to ensure it remains free of debris and operates efficiently. Common issues may include wear or damage to the slinger, which can affect its performance. Troubleshooting steps may involve checking for proper installation, ensuring the slinger is clean and free of obstructions, and replacing the component if significant wear is detected.

Performance Impact

The Cummins 3759619 Oil Slinger has a noticeable impact on engine performance. By ensuring consistent lubrication of engine components, it contributes to smoother operation, reduced friction, and lower wear rates. This can lead to improved fuel efficiency, as the engine operates more efficiently with reduced friction. Additionally, the longevity and reliability of the engine may be enhanced, as proper lubrication is a key factor in preventing premature wear and component failure 3.

Cummins Overview

Cummins Inc. is a well-established manufacturer in the heavy-duty truck industry, known for its high-quality engines and components. With a history of innovation and commitment to excellence, Cummins has built a reputation for producing reliable and efficient powertrain solutions. The company’s expertise in engine technology and component design is reflected in products like the Cummins 3759619 Oil Slinger, which are engineered to meet the demanding requirements of heavy-duty applications.

Role of Part 3759619 Oil Slinger in Engine Systems

The Cummins 3759619 Oil Slinger is an essential component in maintaining the lubrication and performance of various engine systems, particularly in turbocharged applications.

In an aftermarket turbocharger setup, the Oil Slinger ensures that the rotating assembly receives consistent lubrication. This is vital for the longevity and efficiency of the turbocharger.

When integrated with the core and housing assembly, the Oil Slinger helps in distributing oil to the core assembly and core assembly 4LGK, ensuring that all moving parts within the turbocharger are adequately lubricated. This reduces friction and wear, contributing to the overall reliability of the turbocharger.

For the turbocharger HC3 and other similar models, the Oil Slinger plays a significant role in the liner pack by ensuring that the oil reaches the critical rotating components. This is particularly important in high-performance applications where the turbocharger operates under extreme conditions.

In performance parts and turbocharger kits, the inclusion of the Oil Slinger enhances the lubrication system, allowing for smoother operation and increased durability.

When dealing with a turbocharger (no HSG, TRB) or a turbocharger and connection assembly, the Oil Slinger ensures that oil is effectively slung to the bearing surfaces, maintaining optimal lubrication even at high rotational speeds.

For the turbocharger and mounting systems, the Oil Slinger contributes to the stability and performance of the turbocharger by ensuring that all internal components are well-lubricated, reducing the risk of premature failure.

In a turbocharger conversion kit, the Oil Slinger is a key component that facilitates the transition to a new turbocharger by providing reliable lubrication to the new setup.

Overall, the Oil Slinger is a fundamental part in the lubrication system of various turbocharger configurations, enhancing performance, reliability, and longevity of the engine systems it serves.

Conclusion

The Cummins 3759619 Oil Slinger is a critical component in the lubrication system of heavy-duty engines, ensuring that all moving parts receive adequate lubrication. Its robust design and effective oil distribution contribute to improved engine performance, reliability, and longevity. Proper installation, maintenance, and compatibility are key to maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.