This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3820951 Lubricating Oil Pump Gear is a critical component designed to facilitate the operation of heavy-duty trucks by ensuring the efficient circulation of lubricating oil within the engine. This gear is integral to the oil pump system, playing a significant role in maintaining the necessary oil pressure and providing adequate lubrication to various engine components. Its proper function is vital for the overall performance and longevity of the engine 1.

Function and Operation

The Cummins 3820951 operates within the oil pump system by meshing with other gears to create a rotational force that drives the pump. This action facilitates the movement of oil from the sump to the various lubrication points throughout the engine. By maintaining consistent oil pressure, the gear ensures that engine components, such as bearings, pistons, and camshafts, receive the necessary lubrication to reduce friction and wear 2. This consistent lubrication is essential for the engine’s smooth operation and efficiency.

Key Features

The Cummins 3820951 is constructed from high-quality materials, designed to withstand the rigorous demands of heavy-duty truck engines. Its precise design specifications ensure a perfect fit within the oil pump assembly, promoting efficient operation. Unique characteristics of this gear include its robust construction and precise engineering, which enhance its performance and durability under high-stress conditions 3.

Benefits

Utilizing the Cummins 3820951 offers several advantages. It contributes to improved engine efficiency by ensuring optimal oil pressure and lubrication. This results in reduced wear and tear on engine components, leading to enhanced overall performance and reliability of the truck. The gear’s durable construction also means longer service intervals and reduced maintenance costs.

Installation and Maintenance

Proper installation and maintenance of the Cummins 3820951 are crucial for its optimal performance and longevity. Installation should follow manufacturer guidelines to ensure a secure fit and proper alignment within the oil pump system. Regular maintenance, including inspection for wear, proper lubrication, and timely replacement when necessary, is recommended to prevent issues and ensure the gear continues to function effectively.

Troubleshooting

Common issues with the Lubricating Oil Pump Gear may include noise, decreased oil pressure, or engine performance issues. These problems can often be traced back to wear on the gear teeth, misalignment, or contamination within the oil system. Troubleshooting steps may involve inspecting the gear for signs of wear, checking the alignment within the pump, and ensuring the oil is clean and at the proper level. Addressing these issues promptly can prevent more significant engine problems.

Manufacturer Information

Cummins Inc. is a renowned manufacturer with a long-standing reputation in the industry for producing high-quality automotive components for commercial vehicles. The company’s commitment to innovation, quality, and customer satisfaction is evident in its wide range of products, including the Cummins 3820951. Cummins’ expertise in engine technology and component manufacturing ensures that their products meet the demanding requirements of heavy-duty applications.

Compatibility

The Cummins part number 3820951 is designed to fit into several specific engine models. This part is integral to the proper functioning of the engine’s lubrication system, ensuring that oil is circulated effectively to maintain engine health.

N14 CELECT and N14 MECHANICAL Engines

The 3820951 is compatible with both the N14 CELECT and N14 MECHANICAL engines. These engines are known for their robust design and are widely used in heavy-duty applications. The oil pump gear in these engines plays a crucial role in maintaining the oil flow, which is essential for the engine’s longevity and performance.

NH/NT 855 Engines

Similarly, the 3820951 part is also suitable for the NH/NT 855 engines. These engines are part of the Cummins lineup and are recognized for their reliability and efficiency in various industrial applications. The oil pump gear ensures that the lubrication system operates smoothly, reducing wear and tear on engine components.

Role of Part 3820951 in Engine Systems

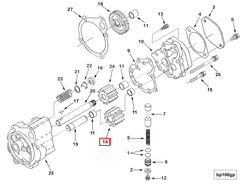

The Part 3820951 is an essential component within the lubricating oil pump system, ensuring the efficient circulation of oil throughout various engine components. This gear operates in conjunction with other parts to maintain optimal lubrication, which is vital for the longevity and performance of the engine.

Integration with Base Parts and Short Blocks

When installed in base parts or a short block, the lubricating oil pump gear works to drive the pump mechanism. In configurations such as the NTC-300, NTC-350, and NTC-400 cylinder short blocks, this gear ensures that oil is consistently delivered to critical areas, including the crankshaft, camshaft, and valve train. The gear’s precise engagement with the pump ensures that oil pressure remains stable, facilitating smooth operation and reducing wear.

Function within Lubricating Oil Pump Systems

In systems like the EBM: Pump, Lub Oil and Lube Pump, the gear is a fundamental element. It meshes with the pump’s internal components to create the necessary pressure for oil distribution. Whether part of a Lubricating Oil Pump Kit or a Lubricating Pump Conversion Kit, the gear’s role is to translate rotational motion into hydraulic pressure, which is then used to lubricate various engine parts.

Interaction with Service Kits and Assemblies

When incorporated into a Service Kit & Pump, Lub Oil, the gear enhances the pump’s reliability and efficiency. In a Short Assembly Block or Short Block Kit, it ensures that all moving parts receive adequate lubrication, minimizing friction and heat generation. The gear’s consistent performance is key to maintaining the integrity of the lubrication system, which is especially important in high-stress environments.

Comprehensive Lubrication System

The lubricating oil pump gear is also integral to the Gear Box and the broader Lubricating Oil Pump system. It collaborates with other components to form a cohesive lubrication network that supports the engine’s dynamic operations. By ensuring that oil is efficiently circulated, the gear contributes to the overall health and performance of the engine, safeguarding against potential damage from inadequate lubrication.

Conclusion

The Cummins 3820951 Lubricating Oil Pump Gear is a vital component for the efficient operation and longevity of heavy-duty truck engines. Its role in maintaining optimal oil pressure and lubrication is crucial for reducing wear and tear on engine components, enhancing overall performance, and ensuring reliability. Proper installation, maintenance, and timely troubleshooting are essential for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.