This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3862530 Oil Seal is a critical component for commercial trucks, designed to maintain the integrity of the engine or transmission system by preventing oil leaks. This ensures the engine operates efficiently and reliably within optimal parameters 1.

Basic Concepts of Oil Seals

An oil seal, or rotary shaft seal, is a mechanical device that prevents lubricant leakage from rotating equipment while keeping contaminants out. It consists of an elastomeric sealing element and a metal casing, maintaining contact with both the rotating shaft and the stationary housing to create a barrier 2.

Purpose of the Cummins 3862530 Oil Seal

This Cummins part is engineered to fit within the engine or transmission system of a truck. Its primary function is to seal the interface between rotating and stationary components, such as the crankshaft or transmission shaft, ensuring oil remains within the system for necessary lubrication and preventing contamination 3.

Key Features

The Cummins 3862530 Oil Seal is characterized by its robust material composition, featuring a durable elastomer for the sealing lip and a metal casing for structural support. The design includes precision-engineered tolerances for a snug fit and effective sealing, and may incorporate anti-rotation features to maintain proper orientation during operation 4.

Benefits of Using the Cummins 3862530 Oil Seal

Utilizing this part offers several advantages. It contributes to improved engine efficiency by ensuring consistent lubrication and reducing the risk of oil leaks. The seal’s durable construction promotes longevity, minimizing the need for frequent replacements. Furthermore, its reliable performance helps maintain the overall reliability of the truck, supporting consistent operation under various conditions 1.

Installation Considerations

Proper installation of the Cummins 3862530 Oil Seal is essential for its effective performance. It should be installed with the correct orientation, ensuring that the sealing lip faces the lubricant. The seal must be seated properly within the housing to avoid damage and ensure a tight fit. Careful handling during installation helps prevent contamination and ensures the seal’s integrity 2.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 3862530 Oil Seal involves inspecting it for signs of wear or damage during routine service intervals. Common issues may include oil leaks, which can indicate a failed seal, or contamination that could impair its function. Troubleshooting methods include checking for proper installation, ensuring the seal is not exposed to excessive heat or abrasion, and replacing it if necessary to maintain system integrity 3.

Manufacturer Overview - Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and related components. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial truck industry. The company’s extensive product range and commitment to customer satisfaction underscore its position as a trusted provider of automotive and heavy-duty truck parts 4.

Cummins Oil Seal 3862530 Compatibility

The Cummins Oil Seal part number 3862530 is designed to fit seamlessly within the engine systems of the L10 CELECT and L10 MECHANICAL engines. This oil seal plays a crucial role in maintaining the integrity of the engine by preventing oil leaks, which can lead to decreased performance and potential engine damage.

L10 CELECT Engine

For the L10 CELECT engine, the oil seal 3862530 is engineered to fit precisely in areas where it is most needed to ensure optimal sealing. This engine is known for its advanced electronic control systems, and the oil seal is a critical component in maintaining the cleanliness and efficiency of the engine’s lubrication system.

L10 MECHANICAL Engine

Similarly, in the L10 MECHANICAL engine, the oil seal 3862530 is designed to provide a reliable barrier against oil leakage. This engine variant relies on mechanical systems for its operation, and the oil seal ensures that the engine’s lubrication system remains uncontaminated and efficient.

Both engines benefit from the use of this oil seal, as it helps to maintain the overall health and longevity of the engine by preventing oil from escaping critical areas 4.

Role of Part 3862530 Oil Seal in Engine Systems

The 3862530 Oil Seal is a fundamental component in maintaining the integrity and efficiency of various engine systems. Its primary function is to prevent oil leakage while allowing smooth operation of moving parts. Here’s how it integrates with specific components:

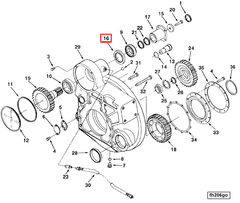

Flywheel Top-Level Assembly Housing

In the flywheel top-level assembly housing, the 3862530 Oil Seal ensures that lubricants remain contained within the system. This is vital for reducing friction between the flywheel and its housing, thereby enhancing the durability and performance of the assembly.

Housing and Flywheel RPTO

When installed in the housing of the flywheel RPTO (Rear Power Take-Off), the oil seal plays a significant role in sealing the interface between the flywheel and the housing. This prevents oil from escaping, which could lead to inadequate lubrication and increased wear on the flywheel components.

Rear Gear Housing

In the rear gear housing, the 3862530 Oil Seal is positioned to maintain the oil level necessary for the gears. Proper sealing ensures that the gears remain well-lubricated, reducing the risk of overheating and mechanical failure.

Power Take-Off Housing

Within the power take-off housing, the oil seal is crucial for maintaining the oil reservoir that lubricates the PTO components. Effective sealing here ensures that the PTO operates smoothly, transferring power efficiently without the risk of oil contamination or loss.

Overall, the 3862530 Oil Seal is a fundamental component in these engine systems, contributing to their reliability and longevity by ensuring consistent lubrication and preventing oil leaks 4.

Conclusion

The Cummins 3862530 Oil Seal is an essential component for maintaining the efficiency and reliability of commercial truck engines. Its robust design, precise engineering, and compatibility with specific engine systems make it a critical part for preventing oil leaks and ensuring consistent lubrication. Proper installation, regular maintenance, and understanding its role in various engine components are key to maximizing its benefits and ensuring the longevity of the engine system 4.

-

Sclar, D. (2008). Auto Repair for Dummies: 2nd Edition. For Dummies.

↩ ↩ -

Drozdziel, P. (2023). The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge.

↩ ↩ -

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ ↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for L9 CM2670 L128B, Bulletin Number 5504588.

↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.