This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

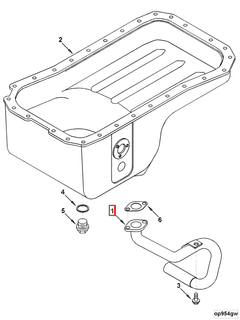

The Oil Suction Connection 3863225 is a component manufactured by Cummins, a well-established name in the commercial truck industry. This part is integral to the operation of commercial trucks, specifically within the engine’s lubrication system. Cummins, known for its commitment to quality and innovation, produces this component to ensure reliable and efficient engine performance 1.

Basic Concepts of Oil Suction Connections

An oil suction connection is a part of the engine lubrication system that facilitates the flow of oil from the oil pan to the engine’s oil pump. Its function is to maintain a consistent supply of oil to the pump, ensuring that the engine components receive adequate lubrication. This connection operates under the principle of suction, where the pump creates a vacuum that draws oil through the connection into the lubrication circuit 2.

Purpose and Role in Truck Operation

The Oil Suction Connection 3863225 plays a specific role in the engine of a commercial truck by ensuring a steady flow of oil to the pump. This consistent oil supply is vital for the lubrication of moving parts within the engine, reducing friction and wear. By maintaining proper lubrication, the connection contributes to the engine’s overall performance and reliability, helping to prevent overheating and component failure 3.

Key Features

The Oil Suction Connection 3863225 is designed with several features that enhance its functionality. It is constructed from durable materials to withstand the high pressures and temperatures within the engine compartment. The design includes precise threading and sealing surfaces to ensure a secure fit and prevent leaks. Additionally, the connection may feature anti-drainback valves or other mechanisms to maintain oil levels in the sump, ensuring immediate availability when the engine starts 4.

Benefits

The use of the Oil Suction Connection 3863225 offers several benefits. It provides improved engine lubrication, which is crucial for the longevity of engine components. The design and materials used in its construction contribute to increased durability, reducing the likelihood of failure under operating conditions. Furthermore, by ensuring efficient oil flow and reducing the risk of engine damage, this component can lead to potential cost savings through enhanced performance and reduced maintenance needs.

Installation Process

Installing the Oil Suction Connection 3863225 requires careful attention to detail to ensure proper fitting. The process involves cleaning the installation area, applying the appropriate sealant to the threading, and carefully screwing the connection into place. It is important to use the correct tools to avoid over-tightening, which could damage the threading or the connection itself. Following the manufacturer’s guidelines for torque specifications is crucial to ensure a secure and leak-free installation.

Troubleshooting Common Issues

Common issues with oil suction connections include leaks and blockages. Leaks may occur due to improper installation, damaged threading, or degradation of sealing materials. Blockages can result from debris within the oil or a malfunction of internal components, such as an anti-drainback valve. Troubleshooting these issues involves inspecting the connection for visible signs of damage, checking the oil for contaminants, and ensuring that all components are functioning as intended.

Maintenance Tips

Regular maintenance of the Oil Suction Connection 3863225 is important for its longevity and efficient operation. This includes periodic inspection for signs of wear or damage, cleaning the connection and surrounding area to prevent debris accumulation, and ensuring that all seals and gaskets are in good condition. Following the manufacturer’s recommended maintenance schedule can help identify potential issues before they lead to more significant problems.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s product range includes a variety of engine components and systems designed to meet the demanding requirements of commercial vehicles. Cummins’ commitment to quality is evident in its rigorous testing and quality control processes, ensuring that each component, including the Oil Suction Connection 3863225, meets the highest standards of performance and durability.

Compatibility with Cummins Engines

-

4B3.9 and B4.5 Engines The Oil Suction Connection part 3863225 is designed to fit seamlessly with the 4B3.9 and B4.5 engines. These engines are known for their reliability and efficiency in various applications, from agricultural to industrial use. The part’s design ensures a secure and leak-free connection, maintaining the integrity of the oil system.

-

QSB3.9 30 CM550 Engine The QSB3.9 30 CM550 engine, part of Cummins’ QSB series, is engineered for heavy-duty applications. The Oil Suction Connection part 3863225 is specifically engineered to meet the demands of this robust engine, providing a reliable method for oil suction. This ensures that the engine operates smoothly and efficiently, even under heavy loads.

Each of these engines benefits from the precision engineering of the Oil Suction Connection part 3863225, ensuring optimal performance and longevity.

Conclusion

The Oil Suction Connection 3863225 is an essential component in the efficient operation of engine systems, particularly in its interaction with the oil pan and the overall lubrication system. When integrated into an engine system, the Oil Suction Connection is typically mounted on the oil pan. Its primary function is to draw oil from the pan and direct it towards the oil pump. This process is fundamental for maintaining a consistent oil flow throughout the engine, ensuring that all moving parts are adequately lubricated.

The connection point between the Oil Suction Connection and the oil pan is designed to be secure and leak-proof, which is vital for preventing oil loss and maintaining the correct oil level within the engine. The efficiency of this connection directly influences the performance of the oil pump, as a stable and uninterrupted oil supply is necessary for the pump to operate effectively.

In summary, the role of the part 3863225 Oil Suction Connection in engine systems is to facilitate a reliable and efficient transfer of oil from the pan to the pump, contributing to the overall lubrication and cooling of engine components.

-

Pulkrabek, W. W. (2014). Engineering Fundamentals of the Internal Combustion Engine. Pearson Education.

↩ -

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩ -

Singh, D. K. (2024). Dictionary of Mechanical Engineering. Springer Nature.

↩ -

Nunney, M. J. (2007). Light and Heavy Vehicle Technology, Fourth Edition. Butterworth-Heinemann.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.