This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

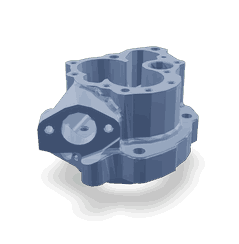

The Lubricating Oil Pump Housing 3865155 by Cummins is a component designed to facilitate the efficient operation of heavy-duty trucks. It plays a role in the lubrication system by ensuring that engine components receive the necessary oil flow to reduce friction, dissipate heat, and prevent wear. This Cummins part is integral to maintaining the performance and longevity of the engine.

Basic Concepts of Lubricating Oil Pump Housing

Lubricating oil pump housings are designed to circulate oil throughout the engine, maintaining the necessary pressure to ensure that all moving parts are adequately lubricated. This circulation is vital for reducing friction between components, which in turn helps to minimize heat generation and wear. The housing itself provides a structural framework that supports the pump mechanism and directs the flow of oil to where it is needed most 1.

Purpose of the 3865155 Lubricating Oil Pump Housing

The 3865155 Lubricating Oil Pump Housing is specifically engineered to enhance the operation of Cummins engines in heavy-duty trucks. It contributes to engine performance by ensuring consistent oil pressure and flow, which is crucial for the efficient functioning of engine components. By maintaining optimal lubrication, this housing helps to extend the engine’s operational life and improve overall reliability 2.

Key Features

The 3865155 Lubricating Oil Pump Housing boasts several key features that enhance its functionality. It is constructed from durable materials that can withstand the high pressures and temperatures within the engine environment. The design includes precise engineering to ensure a snug fit and efficient oil flow. Additionally, it may incorporate features such as integrated gaskets or seals to prevent leaks and maintain system integrity.

Benefits

Utilizing the 3865155 Lubricating Oil Pump Housing offers several advantages. It contributes to improved engine efficiency by ensuring that all components are properly lubricated, which reduces friction and heat. This can lead to reduced wear and tear on engine parts, enhancing the engine’s longevity. Furthermore, the reliable operation of this housing supports the overall reliability of the engine, providing peace of mind to truck operators 3.

Installation Process

Installing the 3865155 Lubricating Oil Pump Housing requires careful attention to detail. The process involves securing the housing in place within the engine, ensuring that all connections are tight and that the oil passages are clear. It is important to use the appropriate tools and follow manufacturer guidelines to avoid damage to the housing or surrounding components. Proper installation is key to ensuring the housing functions as intended.

Maintenance Tips

To ensure the optimal performance of the 3865155 Lubricating Oil Pump Housing, regular maintenance is recommended. This includes inspecting the housing for signs of wear or damage, cleaning any debris that may accumulate, and ensuring that all seals and gaskets are in good condition. Following the manufacturer’s guidelines for lubrication and maintenance intervals will help to prolong the life of the housing and maintain engine efficiency.

Troubleshooting Common Issues

Common issues with the 3865155 Lubricating Oil Pump Housing may include leaks, unusual noise, or inadequate oil pressure. Addressing these problems promptly is important to prevent further damage to the engine. Solutions may involve tightening connections, replacing worn seals or gaskets, or in some cases, replacing the housing itself. Regular inspections can help identify potential issues before they become serious problems.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a strong reputation in the automotive industry, Cummins is known for producing high-quality engines and components that are designed to deliver reliable performance in demanding applications. The company’s commitment to innovation and customer satisfaction has established it as a trusted name in the production of diesel engines and related parts.

Compatibility of Cummins Lubricating Oil Pump Housing (Part 3865155)

The Cummins Lubricating Oil Pump Housing, identified by part number 3865155, is a critical component in the engine’s lubrication system. This part ensures that oil is properly circulated throughout the engine, maintaining optimal lubrication and reducing wear and tear. The compatibility of this part with various engine models is crucial for ensuring engine performance and longevity.

Compatible Engines

- G855 Series

- G855

- G855 CM558

- GTA855 CM558 (CM2358) G101

The G855 series engines, including the G855, G855 CM558, and GTA855 CM558 (CM2358) G101, are designed for heavy-duty applications. The lubricating oil pump housing part 3865155 is engineered to fit seamlessly with these engines, ensuring efficient oil flow and maintaining the high standards of performance expected from these models.

- N14 Series

- N14 CELECT PLUS

- N14 G

- N14 MECHANICAL

The N14 series engines, such as the N14 CELECT PLUS, N14 G, and N14 MECHANICAL, are known for their reliability and durability. The lubricating oil pump housing part 3865155 is specifically designed to integrate with these engines, providing the necessary lubrication to keep them running smoothly and efficiently.

- NH/NT 855

The NH/NT 855 engine is another model that benefits from the use of the lubricating oil pump housing part 3865155. This part ensures that the engine’s lubrication system operates effectively, contributing to the overall performance and longevity of the engine.

- QSN14 Series

- QSN14 CM876 N103

- QSNT14 CM876 N102

The QSN14 series engines, including the QSN14 CM876 N103 and QSNT14 CM876 N102, are designed for demanding applications. The lubricating oil pump housing part 3865155 is compatible with these engines, ensuring that they receive the proper lubrication needed to perform at their best.

By ensuring that the lubricating oil pump housing part 3865155 is correctly matched with the appropriate engine models, users can maintain the integrity and performance of their engines, preventing potential issues related to inadequate lubrication.

Role of Part 3865155 Lubricating Oil Pump Housing in Engine Systems

The part 3865155 Lubricating Oil Pump Housing is integral to the operation of several key components within engine systems. It serves as the foundational structure for the Lubricating Oil Pump, ensuring that the pump is securely mounted and aligned within the engine assembly. This housing facilitates the efficient transfer of lubricating oil from the sump to various engine parts, maintaining optimal lubrication and reducing friction.

In conjunction with the Lubricating Oil Pump Body, the housing forms a sealed environment that prevents oil leaks and maintains consistent oil pressure. This is essential for the longevity and performance of the engine. The housing also interacts with the Lubricating Pump and Oil Pump components, providing a stable platform for these parts to operate effectively.

When considering the Lubricating Oil Pump Kit and Overhaul Kit, the housing plays a significant role in ensuring that all components are correctly installed and function as intended. It is also compatible with Base Parts and Kit On Board Spares, offering a versatile solution for maintenance and repair scenarios.

Additionally, the housing is designed to work seamlessly with the Auxiliary Pump, enhancing the overall lubrication system by providing supplementary oil flow when needed. This integration ensures that even under demanding conditions, the engine remains well-lubricated, thereby enhancing its reliability and performance.

Conclusion

The 3865155 Lubricating Oil Pump Housing by Cummins is a vital component in the lubrication system of heavy-duty engines. Its role in ensuring efficient oil circulation, reducing friction, and maintaining engine performance cannot be overstated. Proper installation, regular maintenance, and prompt troubleshooting of common issues are essential for maximizing the benefits of this part. By understanding its key features, benefits, and compatibility with various engine models, users can ensure the longevity and reliability of their engines.

-

Livesey, A. (2000). The Repair of Vehicle Bodies. Elsevier.

↩ -

Naunheimer, H., Bertsche, B., Ryborz, J., & Novak, W. (2011). Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg.

↩ -

Reif, K. (Ed.). (2015). Gasoline Engine Management Systems and Components. Springer Vieweg.

↩

SPECIFICATIONS

BILL OF MATERIALS

| Name | Quantity | Part Number |

|---|---|---|

| Bushing | 2 | 69521 |

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.