This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

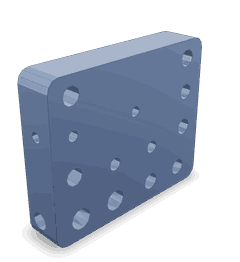

The 3866145 Oil Block Connection is a component manufactured by Cummins, a well-established name in the automotive industry, particularly known for its heavy-duty truck engines. This part is integral to the lubrication system of these engines, ensuring that oil is efficiently distributed to critical components, thereby supporting engine performance and longevity 1.

Basic Concepts of Oil Block Connection

An Oil Block Connection is a component that facilitates the flow of oil within the engine block. Its primary function is to ensure that oil reaches various engine parts that require lubrication, such as bearings and pistons. By maintaining a consistent oil flow, it contributes to the reduction of friction and wear, which are vital for the engine’s smooth operation and durability 2.

Purpose of the 3866145 Oil Block Connection

The 3866145 Oil Block Connection plays a role in directing oil flow within the engine, ensuring that all necessary components receive adequate lubrication. This part helps in maintaining engine health by preventing metal-to-metal contact, which can lead to excessive wear and potential engine failure. Its design allows for efficient oil distribution, which is crucial for the optimal performance of heavy-duty truck engines 3.

Key Features

The 3866145 Oil Block Connection is constructed from durable materials that can withstand the high pressures and temperatures within an engine. Its design includes precise fittings and connections that ensure a secure and leak-free installation. Additionally, it may feature unique attributes such as enhanced sealing mechanisms or corrosion-resistant coatings, which contribute to its performance and longevity.

Benefits

Utilizing the 3866145 Oil Block Connection can lead to improved engine efficiency, as proper lubrication reduces friction and allows for smoother operation. This part also contributes to the longevity and reliability of the engine, as consistent oil flow helps prevent wear and tear on critical components. Moreover, its robust construction ensures that it can endure the demanding conditions of heavy-duty truck engines.

Installation Process

Installing the 3866145 Oil Block Connection requires careful attention to ensure a secure fit. The process involves cleaning the installation area, applying the appropriate sealant if necessary, and using the correct tools to tighten the connections. It is important to follow the manufacturer’s guidelines to avoid over-tightening, which could damage the part or lead to leaks.

Maintenance Tips

Regular maintenance of the 3866145 Oil Block Connection is vital for ensuring optimal performance. This includes periodic inspections for signs of wear or damage, cleaning the area around the connection to prevent debris buildup, and checking for any leaks. Adhering to recommended inspection intervals and performing routine cleaning can help maintain the efficiency and reliability of the lubrication system.

Troubleshooting Common Issues

Common issues with the 3866145 Oil Block Connection may include leaks or blockages. If a leak is detected, it is important to identify the source and address it promptly to prevent oil loss and potential engine damage. Blockages can be resolved by cleaning the connection or, if necessary, replacing the part. Regular maintenance can help prevent these issues from arising.

About Cummins

Cummins is a renowned manufacturer in the automotive industry, with a strong reputation for producing high-quality components for heavy-duty engines. The company has a long history of innovation and commitment to excellence, which is reflected in the durability and performance of its products. Cummins’ dedication to quality and customer satisfaction has established it as a trusted name in the industry.

Compatibility with Cummins Engines

-

6B5.9 Engine Series

- The 3866145 Oil Block Connection is specifically tailored to fit within the 6B5.9 engine series. This part is essential for maintaining the engine’s lubrication pathways, ensuring that oil is efficiently routed from the oil pan to the engine block and subsequently to the oil filter and other critical components.

-

Other Cummins Engine Models

- While the primary focus here is on the 6B5.9 engine series, the 3866145 Oil Block Connection is also compatible with other Cummins engine models. This part is designed to meet the stringent standards set by Cummins, ensuring that it can be used across multiple engine types without compromising on performance or reliability.

Importance in Engine Operation

The Oil Block Connection part 3866145 plays a pivotal role in the engine’s overall health and longevity. By providing a secure and leak-proof connection between the oil pan and the engine block, this part helps to prevent oil leaks, which can lead to engine damage if left unaddressed. Additionally, it ensures that the engine’s lubrication system operates at peak efficiency, which is crucial for maintaining optimal engine performance and reducing wear and tear on engine components.

Role of Part 3866145 Oil Block Connection in Engine Systems

The part 3866145 Oil Block Connection is an integral component in the orchestration of various engine systems, ensuring seamless operation and optimal performance.

Integration with Engine Systems

-

Lubrication System: The Oil Block Connection facilitates the distribution of lubricant throughout the engine. It interfaces with the oil pump, allowing pressurized oil to be channeled to critical moving parts such as bearings, pistons, and camshafts. This ensures reduced friction and wear, promoting longevity and efficiency.

-

Cooling System: Efficient heat management is vital for engine performance. The Oil Block Connection works in tandem with the cooling system by allowing oil to absorb heat from various engine components and transfer it to the oil cooler. This process helps maintain optimal operating temperatures and prevents overheating.

-

Fuel Injection System: In modern engines, the Oil Block Connection may also interact with the fuel injection system. It ensures that the high-pressure oil required for operating fuel injectors is delivered consistently. This integration enhances fuel atomization and combustion efficiency, leading to better performance and reduced emissions.

-

Engine Monitoring System: The Oil Block Connection plays a role in the engine monitoring system by providing data points for oil pressure and temperature sensors. These sensors feed information to the engine control unit (ECU), allowing for real-time adjustments to maintain optimal engine conditions.

-

Exhaust Gas Recirculation (EGR) System: In engines equipped with EGR systems, the Oil Block Connection may assist in managing the flow of exhaust gases that are recirculated back into the intake manifold. This helps in reducing nitrogen oxides (NOx) emissions and improving overall engine efficiency.

-

Variable Valve Timing (VVT) System: Many modern engines utilize VVT to optimize performance across different operating conditions. The Oil Block Connection ensures that the oil required to operate the VVT actuators is delivered precisely when needed, allowing for dynamic adjustments to valve timing.

By understanding the multifaceted role of the Oil Block Connection within these systems, engineers and mechanics can better appreciate its significance in maintaining engine health and performance.

Conclusion

The 3866145 Oil Block Connection is a critical component in Cummins engines, ensuring efficient oil distribution and integration with various engine systems. Its robust design and compatibility with multiple engine models make it a reliable choice for maintaining engine performance and longevity. Regular maintenance and proper installation are essential to maximize the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.