This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

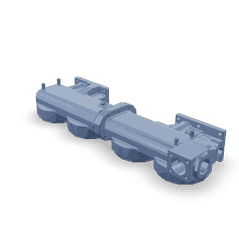

The Lubricating Oil Filter Head 3872549, manufactured by Cummins, is a critical component for the operation of commercial trucks. Cummins is renowned in the automotive industry for its robust and reliable engine components. This part is designed to ensure the efficient functioning of the engine’s lubrication system, contributing to the overall performance and longevity of the engine 1.

Function and Operation

This Cummins part operates within the engine’s lubrication system by facilitating the filtration of contaminants from the oil. As oil circulates through the engine, it picks up debris, metal particles, and other impurities that can cause wear and damage. The filter head houses the oil filter, which traps these contaminants, allowing clean oil to continue its path through the engine. This process helps maintain the viscosity and cleanliness of the oil, which is vital for reducing friction and wear on engine components 2.

Key Features

The design and construction of the Lubricating Oil Filter Head 3872549 incorporate several features that enhance its performance. Constructed from durable materials, the filter head is built to withstand the high pressures and temperatures within the engine environment. It features precise sealing mechanisms to ensure a secure fit and prevent oil leaks. Additionally, the filter head may include unique attributes such as anti-drainback valves, which help maintain oil pressure during engine shutdown, ensuring immediate lubrication upon restart 3.

Benefits

The Lubricating Oil Filter Head 3872549 offers several advantages that contribute to engine health and performance. By effectively filtering contaminants, it helps protect engine components from premature wear and damage. This results in improved engine protection and can extend the life of the oil, reducing the frequency of oil changes. Furthermore, the enhanced filtration leads to better overall engine performance, as clean oil ensures optimal lubrication and cooling of moving parts 4.

Installation and Compatibility

Proper installation of the Lubricating Oil Filter Head 3872549 is crucial for its effective operation. Installation guidelines should be followed to ensure a secure and leak-free connection. Specific requirements may vary depending on the truck model and engine type, so it is important to consult the manufacturer’s instructions or a professional technician to ensure compatibility and correct installation.

Maintenance and Troubleshooting

Routine maintenance of the Lubricating Oil Filter Head 3872549 is necessary to ensure its optimal performance. This includes regular inspection for signs of wear or damage, and ensuring that the sealing mechanisms are intact. Troubleshooting common issues, such as oil leaks or reduced filtration efficiency, may involve checking the condition of the oil filter and the integrity of the filter head’s connections. Following the manufacturer’s recommended maintenance schedule will help prevent issues and ensure the longevity of the component.

Cummins Overview

Cummins is a leading manufacturer in the commercial truck industry, known for its high-quality engine components and systems. With a rich history of innovation and reliability, Cummins offers a wide range of products designed to meet the demanding requirements of commercial transportation. The company’s reputation for durability and performance makes its components, like the Lubricating Oil Filter Head 3872549, a preferred choice for fleet operators and maintenance professionals.

Role of Part 3872549 Lubricating Oil Filter Head in Engine Systems

The 3872549 lubricating oil filter head is an integral component in the operation of engine systems, specifically within the lubrication circuit. This component interfaces directly with the lubricating oil filter, facilitating the filtration process that is essential for maintaining engine health.

When the engine is operational, the oil pump draws lubricant from the oil pan and propels it through the lubrication circuit. The lubricating oil filter head acts as a junction point where the unfiltered oil enters the system. It ensures a secure connection between the oil filter and the engine block, allowing oil to flow into the filter media where contaminants are trapped.

As oil passes through the filter media, impurities such as metal particles, carbon deposits, and other debris are removed, ensuring that only clean oil circulates through the engine’s moving parts. The filtered oil then exits the lubricating oil filter head and is distributed to critical engine components, including the crankshaft, camshaft, pistons, and bearings.

The lubricating oil filter head also incorporates a bypass valve, which is a safety feature that allows oil to bypass the filter if it becomes clogged, ensuring that the engine continues to receive lubrication even under adverse conditions. This valve is calibrated to open at a specific pressure differential, safeguarding the engine from damage due to lack of lubrication.

Furthermore, the lubricating oil filter head often includes an anti-drainback valve. This valve prevents oil from draining out of the filter when the engine is turned off, ensuring that there is immediate oil pressure upon startup, which is vital for the protection of engine components during the initial moments of operation.

Conclusion

In summary, the 3872549 lubricating oil filter head is a key element in the engine’s lubrication system, ensuring that the oil delivered to engine components is clean and that the system can handle various operational scenarios without compromising engine integrity.

-

Xin, Qianfan. Diesel Engine System Design. Woodhead Publishing Limited, 2011.

↩ -

Reif, Konrad. Diesel Engine Management Systems and Components. Springer, 2014.

↩ -

Bennett, Sean. Modern Diesel Technology Light Duty Diesels. Cengage Learning, 2012.

↩ -

Schneider, Wolf-Henning. Pistons and Engine Testing. Springer Nature, 2016.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.