This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

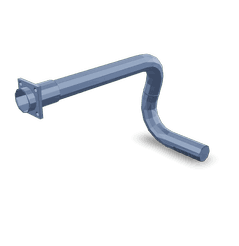

The Lubricating Oil Suction Tube, identified by part number 3877071, is a component manufactured by Cummins, a leader in diesel engine technology. This tube is integral to the lubrication system of heavy-duty trucks, facilitating the efficient circulation of oil throughout the engine 1.

Function and Operation

The Lubricating Oil Suction Tube operates by drawing oil from the sump, the lowest part of the engine where oil collects, and delivering it to the oil pump. This process ensures a continuous supply of lubricant to the engine’s moving parts, which is vital for reducing friction and wear 2.

Purpose of the Lubricating Oil Suction Tube

The primary role of the Lubricating Oil Suction Tube is to maintain proper lubrication within the engine. By ensuring a steady flow of oil, it helps in the smooth operation of engine components and contributes to their longevity. Proper lubrication is key to minimizing wear and tear, preventing overheating, and enhancing overall engine efficiency 3.

Key Features

The Lubricating Oil Suction Tube is designed with specific features to enhance its effectiveness and durability. It is typically constructed from high-quality materials that resist corrosion and wear. The tube may include unique design elements such as reinforced sections to withstand high pressure and flexible joints to accommodate engine movement. These features contribute to the tube’s reliability and longevity in demanding operating conditions 4.

Benefits

The Lubricating Oil Suction Tube offers several advantages. It improves oil flow within the engine, which is crucial for maintaining optimal lubrication. By ensuring a consistent supply of oil to the pump, it reduces the risk of air ingestion, which can lead to inefficient lubrication and potential engine damage. Additionally, the tube enhances engine protection by supporting the lubrication system’s efficiency, thereby contributing to the engine’s overall performance and durability 5.

Installation Considerations

Proper installation of the Lubricating Oil Suction Tube is crucial for its effective operation. It is important to follow manufacturer guidelines, which may include specific prerequisites such as cleaning the installation area and ensuring the engine is cool. The necessary tools for installation should be gathered beforehand. Steps to ensure a secure and effective fit include verifying the tube’s alignment with the sump and oil pump, securing all connections, and checking for leaks after installation 6.

Maintenance and Troubleshooting

Regular maintenance of the Lubricating Oil Suction Tube is important for ensuring its optimal performance. This includes periodic inspections for signs of wear, corrosion, or damage. Cleaning the tube as part of routine engine maintenance can prevent buildup that might obstruct oil flow. Common issues may include leaks or reduced oil flow, which can often be addressed by tightening connections or replacing worn components 7.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established itself as a pioneer in engine manufacturing, known for its commitment to innovation, quality, and customer satisfaction in the automotive and heavy-duty truck industries 8.

Cummins Lubricating Oil Suction Tube (Part 3877071) Compatibility

The Cummins Lubricating Oil Suction Tube, identified by the part number 3877071, is a critical component in the engine’s lubrication system. This part ensures that oil is effectively drawn from the oil pan and circulated throughout the engine to provide necessary lubrication and cooling.

K38 Engine Series

The K38 engine series is a range of high-performance diesel engines designed for heavy-duty applications. The lubricating oil suction tube in this series is engineered to handle the rigorous demands of these engines, ensuring efficient oil flow and maintaining optimal engine performance. The design of the tube is such that it can withstand the high pressures and temperatures typical of these engines, providing a reliable means of oil circulation 9.

Specific Fitment Details

- Engine Models: The 3877071 oil suction tube is compatible with several models within the K38 series. It is specifically designed to fit seamlessly with the architecture of these engines, ensuring that the oil is drawn efficiently from the oil pan.

- Installation: The installation process involves securing the tube to the oil pan and connecting it to the oil pump. The design allows for easy access and replacement, making maintenance straightforward.

- Performance: By ensuring a steady and unobstructed flow of oil, this part helps in reducing engine wear and tear, thereby extending the engine’s lifespan 10.

Role of Part 3877071 Lubricating Oil Suction Tube in Engine Systems

The lubricating oil suction tube, specifically part 3877071, is an essential component in the oil suction assembly of engine systems. Its primary function is to facilitate the efficient transfer of oil from the oil pan to the engine’s lubrication system.

When the engine is operational, the oil suction tube draws oil from the oil pan, where it is stored after circulating through the engine. This tube is connected to the oil pump, which creates a vacuum to pull the oil through the tube. The oil then travels through the lubrication system, ensuring that all moving parts within the engine receive adequate lubrication.

The efficiency of the lubricating oil suction tube directly impacts the performance and longevity of the engine. A well-functioning tube ensures a consistent oil flow, which is vital for maintaining optimal engine temperature, reducing friction, and preventing wear on critical components 11.

Conclusion

The Lubricating Oil Suction Tube (part number 3877071) by Cummins plays a crucial role in the lubrication system of heavy-duty engines. Its design and function are essential for maintaining optimal engine performance, reducing wear, and ensuring longevity. Proper installation, regular maintenance, and understanding its compatibility with specific engine models are key to maximizing the benefits of this component.

-

Reif, K. (Ed.). (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ -

Denton, T., & Pells, H. (2022). Automotive Technician Training Theory. Routledge.

↩ -

Gifford, C. (2014). Cars Encyclopedia. DK Publishing.

↩ -

Cummins Inc. (n.d.). Service Manual (4388870).

↩ -

Reif, K. (Ed.). (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ -

Denton, T., & Pells, H. (2022). Automotive Technician Training Theory. Routledge.

↩ -

Cummins Inc. (n.d.). Service Manual (4388870).

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (n.d.). Service Manual (4388870).

↩ -

Cummins Inc. (n.d.). Service Manual (4388870).

↩ -

Reif, K. (Ed.). (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.