This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

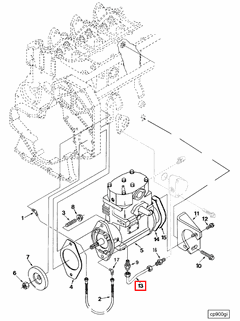

The 3910053 Compressor Oil Drain Tube by Cummins is a component designed to facilitate the drainage of oil from the compressor system in heavy-duty trucks. Its role is significant in ensuring the compressor operates efficiently and maintains longevity 1.

Basic Concepts of Compressor Oil Drain Tubes

Compressor oil drain tubes operate on the principle of managing oil within the compressor system. They allow for the controlled drainage of oil, which is vital for maintaining the compressor’s efficiency and extending its operational life. Proper oil management ensures that the compressor system remains lubricated, cool, and free from contaminants, which can otherwise lead to increased wear and potential system failures 2.

Purpose and Function

This Cummins part plays a role in the compressor system by enabling the efficient drainage of oil. This process helps maintain optimal oil levels within the compressor, ensuring that it operates within its designed parameters. By facilitating regular oil drainage, the tube helps prevent oil buildup, which can lead to increased pressure and temperature within the system, potentially causing damage to compressor components 3.

Key Features

The 3910053 is constructed with materials that offer durability and resistance to the harsh conditions found in heavy-duty truck environments. Its design includes features that enhance performance and reliability, such as precise engineering to ensure a secure fit and effective drainage. The tube’s material composition is chosen to withstand the chemical properties of compressor oil and the physical stresses of the operating environment.

Benefits

The use of the Compressor Oil Drain Tube offers several advantages. It contributes to improved compressor efficiency by ensuring that oil levels are maintained within optimal ranges. This can lead to reduced maintenance requirements, as the compressor system is less likely to suffer from oil-related issues. Additionally, the tube enhances overall system reliability by preventing oil buildup and associated complications.

Installation and Compatibility

Proper installation of this part is important for ensuring its effectiveness. Installation guidelines should be followed to ensure a secure fit and proper function. Compatibility with various truck models and compressor systems is a consideration, and it is important to verify that the tube is suitable for the specific application to ensure optimal performance and integration within the system.

Maintenance and Troubleshooting

Regular maintenance of the 3910053 is recommended to ensure its continued effectiveness. This may include inspection procedures to check for signs of wear or damage, cleaning guidelines to remove any contaminants that may accumulate, and troubleshooting tips for addressing common issues that may arise. Proper maintenance helps ensure that the tube continues to function as intended, contributing to the overall efficiency and reliability of the compressor system.

Safety Considerations

When working with the Compressor Oil Drain Tube, it is important to observe safety practices and precautions. This includes following handling procedures to prevent injury or damage to the component, using personal protective equipment (PPE) as required, and adhering to system shutdown protocols to ensure a safe working environment. Safety is a priority when performing maintenance or repairs on any component of a heavy-duty truck.

Cummins: A Brief Overview

Cummins Inc., the manufacturer of the 3910053, is a company with a long-standing reputation in the automotive industry. Known for its commitment to quality and innovation, Cummins has a history of producing reliable and high-performance components for a variety of applications. The company’s dedication to excellence is reflected in the design and construction of its products, including the 3910053.

Engine Compatibility of Compressor Oil Drain Tube Part 3910053

The Compressor Oil Drain Tube part 3910053, manufactured by Cummins, is a component in the maintenance and operation of certain engine models. This part is designed to facilitate the drainage of oil from the compressor, ensuring that the system operates efficiently and without contamination.

Compatibility with Specific Engines

4B3.9 and 6B5.9 Engines

The Compressor Oil Drain Tube part 3910053 is specifically engineered to fit the 4B3.9 and 6B5.9 engines. These engines are part of a series known for their robust performance and reliability in various industrial applications. The part ensures that oil is effectively drained from the compressor, preventing buildup and maintaining optimal engine performance.

B5.9 G Engine

Similarly, the B5.9 G engine also benefits from the use of the Compressor Oil Drain Tube part 3910053. This engine, part of the broader B5.9 series, is designed for heavy-duty applications where reliability and efficiency are paramount. The drain tube plays a role in maintaining the integrity of the compressor oil system, ensuring that the engine operates smoothly and efficiently.

Importance of the Compressor Oil Drain Tube

The Compressor Oil Drain Tube part 3910053 is for the proper functioning of the engines it fits. By allowing for the efficient drainage of oil, it helps to prevent oil contamination and buildup, which can lead to decreased performance and potential engine damage. This part is a component in the maintenance regimen of the specified engines, ensuring that they continue to operate at peak efficiency.

Role of Part 3910053 Compressor Oil Drain Tube in Engine Systems

The Compressor Oil Drain Tube, identified by part number 3910053, is an integral component in the maintenance and operation of compressor systems within various engine setups. This tube facilitates the drainage of oil from the compressor, ensuring that the compressor operates efficiently and maintains optimal performance.

When integrated into an engine system, the Compressor Oil Drain Tube works in conjunction with the compressor to manage oil levels. As the compressor operates, it circulates oil to lubricate moving parts and reduce friction. Over time, this oil can accumulate contaminants and degrade, necessitating periodic drainage to maintain compressor efficiency and longevity.

In systems where an air campaign kit is utilized, the Compressor Oil Drain Tube plays a supportive role. The campaign kit often includes components designed to enhance the performance and durability of the compressor. By ensuring that the compressor is free from excess or contaminated oil, the drain tube contributes to the overall effectiveness of the campaign kit.

The seamless integration of the Compressor Oil Drain Tube with the compressor and air system components underscores its importance in maintaining a well-functioning engine. Regular drainage of oil not only preserves the compressor’s operational integrity but also supports the consistent delivery of compressed air, which is essential for various engine functions.

Conclusion

The 3910053 Compressor Oil Drain Tube by Cummins is a vital component for maintaining the efficiency and longevity of compressor systems in heavy-duty trucks. Its design and function are crucial for managing oil levels, preventing contamination, and ensuring optimal compressor performance. Proper installation, maintenance, and adherence to safety practices are essential for maximizing the benefits of this part. Cummins’ reputation for quality and innovation is evident in the design and construction of the 3910053, making it a reliable choice for heavy-duty applications.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.