This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

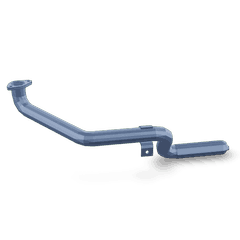

The Oil Suction Connection, identified by part number 3912228 and manufactured by Cummins, is a vital component in the lubrication system of heavy-duty trucks. Cummins, a renowned name in the automotive industry, specializes in the production of diesel engines and related components, ensuring high performance and reliability. This part is integral to maintaining the efficiency and longevity of truck engines by facilitating the proper circulation of oil.

Basic Concepts of Oil Suction Connection

An Oil Suction Connection is a component designed to draw oil from the oil pan and deliver it to the engine’s lubrication system. Its operation is fundamental to the engine’s lubrication process, ensuring that all moving parts receive adequate oil supply to reduce friction, wear, and heat. The connection typically consists of a pipe or fitting that interfaces with the oil pan and the engine’s oil pump, allowing for a continuous flow of oil 1.

Purpose of the Oil Suction Connection

The Oil Suction Connection plays a significant role in the operation of a truck by ensuring efficient oil circulation within the engine. This part is responsible for drawing oil from the oil pan and directing it towards the oil pump, which then circulates the oil throughout the engine. Proper oil circulation is essential for maintaining engine temperature, reducing wear on components, and ensuring smooth operation 2.

Key Features

The Oil Suction Connection is characterized by several key features that enhance its performance and durability. It is typically made from high-quality materials resistant to corrosion and high temperatures, ensuring longevity in demanding environments. The design of this connection may include specific threading or sealing mechanisms to prevent oil leaks and ensure a secure fit within the engine system. Additionally, its construction allows for easy installation and maintenance, contributing to the overall efficiency of engine maintenance procedures 3.

Benefits

The advantages of using the Oil Suction Connection include improved engine lubrication, which leads to reduced friction and wear on engine components. Its durable construction ensures long-term reliability, even under the strenuous conditions typical of heavy-duty truck operations. Furthermore, the efficient design of this connection contributes to the overall efficiency of the oil suction process, ensuring that the engine receives a consistent supply of oil 4.

Installation Process

Installing the Oil Suction Connection requires careful attention to detail to ensure proper function and prevent oil leaks. The process begins with ensuring the engine is cool and the oil has been drained. The old connection, if present, should be removed, and any gaskets or sealing surfaces should be cleaned. The new connection is then installed, ensuring it is securely fastened to prevent leaks. It is advisable to use the appropriate tools and follow manufacturer guidelines to ensure a proper fit and function.

Common Issues and Troubleshooting

Typical problems associated with Oil Suction Connections include oil leaks, blockages, or damage to the connection itself. Diagnosing these issues involves inspecting the connection for signs of wear, corrosion, or misalignment. Troubleshooting steps may include cleaning the connection and sealing surfaces, replacing gaskets, or, in severe cases, replacing the connection entirely. Regular inspections can help identify potential issues before they lead to more significant problems.

Maintenance Tips

To ensure the longevity and optimal performance of the Oil Suction Connection, routine maintenance is recommended. This includes regular inspections for signs of wear or damage, cleaning the connection and surrounding areas to prevent debris accumulation, and ensuring all seals and gaskets are in good condition. Following the manufacturer’s guidelines for maintenance intervals and procedures can help maintain the efficiency of the oil circulation system.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history dating back to 1919, Cummins has established a strong reputation in the automotive industry, particularly for its diesel engines and related components. The company’s commitment to innovation, quality, and customer satisfaction has made it a preferred choice for heavy-duty applications, ensuring that its products, like the Oil Suction Connection part 3912228, meet the high demands of modern engines.

Cummins Engine Compatibility with Oil Suction Connection Part 3912228

The Cummins Oil Suction Connection part 3912228 is designed to fit a variety of Cummins engines, ensuring a secure and efficient oil flow. Here’s a breakdown of its compatibility across different engine models:

ISC Series Engines

- ISC CM2150

- ISC CM554

- ISC CM850

- ISC8.3 CM2250

The Oil Suction Connection part 3912228 is compatible with the ISC series engines, which include the ISC CM2150, ISC CM554, ISC CM850, and ISC8.3 CM2250. This part ensures that the oil suction system functions optimally, maintaining engine performance.

ISL Series Engines

- ISL9 CM2150 SN

- ISL9.5 CM2880 L138

The Oil Suction Connection part 3912228 is also suitable for the ISL series engines, specifically the ISL9 CM2150 SN and ISL9.5 CM2880 L138. This part is engineered to fit these models, ensuring proper oil suction and preventing any potential leaks.

L Series Engines

- L8.9

- L8.9 CM2670 L134C

- L8.9G CMOH2.0 L125B

For the L series engines, including the L8.9, L8.9 CM2670 L134C, and L8.9G CMOH2.0 L125B, the Oil Suction Connection part 3912228 provides a reliable fit. This ensures that the oil suction system operates smoothly, contributing to the overall efficiency and longevity of these engines.

QSC and QSL Series Engines

- QSC8.3 CM554

- QSC8.3 CM850(CM2850)

- QSL8.9 CM2150 L141

- QSL9 CM2250

- QSL9 CM2350 L102

- QSL9 CM850(CM2850)

The Oil Suction Connection part 3912228 is compatible with the QSC and QSL series engines. This includes the QSC8.3 CM554, QSC8.3 CM850(CM2850), QSL8.9 CM2150 L141, QSL9 CM2250, QSL9 CM2350 L102, and QSL9 CM850(CM2850). This part ensures that the oil suction system in these engines is properly maintained, enhancing their operational efficiency.

By ensuring a proper fit across these various engine models, the Cummins Oil Suction Connection part 3912228 plays a crucial role in maintaining the integrity of the oil suction system, thereby contributing to the overall performance and reliability of the engines.

Role of Part 3912228 Oil Suction Connection in Engine Systems

The Oil Suction Connection, identified by part number 3912228, is an integral component in the lubrication system of an engine. Its primary function is to facilitate the transfer of oil from the oil pan to the engine’s lubrication system.

When the engine is operational, the Oil Suction Connection draws oil from the oil pan, where it is stored, into the oil pump. The oil pump then circulates the oil through the engine, ensuring that all moving parts are adequately lubricated. This lubrication is essential for reducing friction, minimizing wear and tear, and dissipating heat generated by the engine’s operation.

The connection between the Oil Suction Connection and the oil pan is typically secured with a gasket to ensure a tight seal, preventing any oil leaks that could lead to inefficient lubrication or environmental contamination. The design of the Oil Suction Connection must accommodate the flow rate required by the oil pump to maintain optimal engine performance.

In summary, the Oil Suction Connection plays a significant role in the engine’s lubrication system by efficiently transferring oil from the oil pan to the oil pump, thereby supporting the engine’s longevity and operational efficiency.

Conclusion

The Oil Suction Connection part 3912228 is a critical component in the lubrication system of heavy-duty engines, ensuring efficient oil circulation and maintaining engine performance. Its durable construction, compatibility with various Cummins engine models, and ease of installation make it a reliable choice for engine maintenance and operation. Regular maintenance and proper installation are essential to maximize the benefits of this part, contributing to the overall efficiency and longevity of the engine.

-

Eret, A. (2024). Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature.

↩ -

Dixon, J. (2014). Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning.

↩ -

Maclaurin, B. (2018). High Speed Off-Road Vehicles. Wiley.

↩ -

Boger, T., & Cutler, W. (2018). Reducing Particulate Emissions in Gasoline Engines. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.