This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3914823 Oil Cooler Tube is designed to facilitate the cooling of engine oil in heavy-duty trucks. It plays a role in maintaining the operational efficiency and longevity of the engine by ensuring that the oil remains within optimal temperature ranges.

Basic Concepts of Oil Cooler Tubes

An oil cooler tube is part of the engine cooling system that helps regulate the temperature of the engine oil. It works by circulating the oil through a series of tubes where it is cooled before being returned to the engine. This process is vital for maintaining the oil’s viscosity and ensuring it performs its lubricating functions effectively 1.

Purpose of the Cummins 3914823 Oil Cooler Tube

The Cummins 3914823 Oil Cooler Tube is specifically designed to enhance the cooling process of engine oil in trucks. By efficiently reducing the temperature of the oil, it aids in maintaining engine performance and extends the engine’s operational life. This tube plays a role in dissipating heat from the oil, which is crucial for preventing overheating and potential engine damage.

Key Features

The Cummins 3914823 Oil Cooler Tube is characterized by its robust design and the materials used in its construction. It is engineered to withstand the high pressures and temperatures associated with heavy-duty truck engines. The tube’s design facilitates efficient heat exchange, and its materials are chosen for their durability and resistance to corrosion, ensuring reliable performance over time.

Benefits of Using the Cummins 3914823 Oil Cooler Tube

Utilizing the Cummins 3914823 Oil Cooler Tube offers several advantages. It contributes to improved engine efficiency by ensuring that the oil remains at an optimal temperature, which in turn reduces wear and tear on engine components. Additionally, it enhances the overall performance of the engine by maintaining the oil’s lubricating properties, leading to smoother operation and potentially extending the engine’s lifespan.

Installation and Integration

Proper installation of the Cummins 3914823 Oil Cooler Tube is crucial for its effective operation. It should be integrated into the truck’s engine system according to the manufacturer’s guidelines to ensure compatibility and efficiency. Careful attention to the installation process helps prevent leaks and ensures that the tube functions as intended within the cooling system.

Maintenance and Care

To ensure the Cummins 3914823 Oil Cooler Tube operates efficiently over its lifespan, regular maintenance and care are recommended. This includes periodic inspections for signs of wear or damage and cleaning the tube to remove any buildup that could impede its function. Adhering to a maintenance schedule helps maintain the tube’s performance and prolongs its service life.

Troubleshooting Common Issues

Common issues with the Cummins 3914823 Oil Cooler Tube may include leaks, blockages, or reduced efficiency. Troubleshooting these problems involves checking for physical damage, ensuring there are no obstructions in the tube, and verifying that it is properly installed. Addressing these issues promptly can help maintain the tube’s effectiveness and prevent more serious engine problems.

Cummins Overview

Cummins Inc. is a well-established manufacturer in the automotive and heavy-duty truck industry, known for its commitment to quality and innovation. With a history of producing reliable and high-performance components, Cummins has built a reputation for excellence in the manufacturing of automotive parts, including the Cummins 3914823 Oil Cooler Tube.

Role of Part 3914823 Oil Cooler Tube in Engine Systems

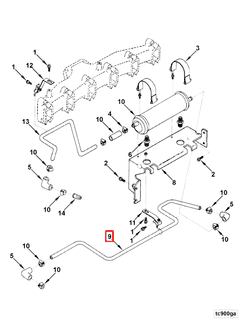

The Part 3914823 Oil Cooler Tube is an essential component in the thermal management of engine systems, specifically within the cooler, torque converter oil, and torque converter cooler subsystems.

In the cooler subsystem, the Oil Cooler Tube facilitates the circulation of engine oil through an external cooling system. This process helps in maintaining optimal oil temperature, which is vital for the longevity and efficiency of the engine. By transferring heat away from the oil, the tube ensures that the oil remains within its ideal operating temperature range, thereby reducing the risk of thermal degradation and improving overall engine performance.

Within the torque converter oil subsystem, the Oil Cooler Tube plays a significant role in regulating the temperature of the torque converter fluid. The torque converter relies on this fluid to transmit power from the engine to the transmission. If the fluid becomes too hot, it can lead to decreased efficiency and potential damage to the torque converter. The Oil Cooler Tube helps in dissipating excess heat, ensuring that the torque converter fluid remains at an optimal temperature for efficient power transmission.

In the torque converter cooler subsystem, the Oil Cooler Tube is integral to the cooling process. This subsystem is designed to further cool the torque converter fluid after it has passed through the torque converter. The Oil Cooler Tube enhances this cooling process by providing a pathway for the fluid to flow through an external cooler, where it can release additional heat. This ensures that the fluid returns to the torque converter at a temperature that promotes efficient operation and prevents overheating.

Overall, the Part 3914823 Oil Cooler Tube is a key component in maintaining the thermal stability of engine systems, contributing to the reliable and efficient operation of the cooler, torque converter oil, and torque converter cooler subsystems.

Conclusion

The Cummins 3914823 Oil Cooler Tube is a vital component in the thermal management of heavy-duty truck engines. Its robust design, efficient heat exchange capabilities, and integration into various engine subsystems highlight its importance in maintaining engine performance and longevity. Regular maintenance and proper installation are crucial for ensuring the tube’s effectiveness and the overall health of the engine.

-

Jazar, R. N. (2017). Vehicle Dynamics: Theory and Application. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.