This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3916285 Oil Cooler Tube is a component designed for use in commercial trucks. It serves a specific function within the engine system, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and operation is key to maintaining the performance of commercial trucks.

Basic Concepts of Oil Cooler Tubes

An oil cooler tube is a part of the engine’s oil cooling system. It facilitates the transfer of heat from the engine oil to the surrounding environment, typically using a liquid-to-air or liquid-to-liquid heat exchange method. The operation of an oil cooler tube is based on the principle of heat transfer, where the tube allows hot oil to pass through and cool down before it is recirculated back into the engine 1.

Purpose of the 3916285 Oil Cooler Tube

This Cummins part plays a role in the engine system by helping to maintain the oil at an optimal temperature. This is achieved by dissipating excess heat from the oil as it circulates through the tube. Maintaining the correct oil temperature is important for engine lubrication, reducing wear, and ensuring efficient operation 2.

Key Features

The 3916285 is constructed with materials that are resistant to corrosion and high temperatures, ensuring durability and longevity. Its design includes features that enhance heat dissipation, such as a specific tube diameter and length that maximize the surface area for heat exchange. Additionally, the tube may have unique characteristics like a reinforced structure to withstand the pressures within the engine system.

Benefits of Using the 3916285 Oil Cooler Tube

Utilizing this part can lead to improved engine performance due to better oil temperature regulation. This can contribute to the longevity of the engine by reducing the stress on engine components that are sensitive to temperature fluctuations. Moreover, the reliability of the truck’s engine system may be enhanced, leading to fewer breakdowns and lower maintenance costs over time 3.

Installation Considerations

When installing the Oil Cooler Tube, it is important to follow manufacturer guidelines to ensure proper fitment and function. This may involve checking for any prerequisites such as the condition of the surrounding components or the need for special tools. Careful attention to the installation process helps to avoid potential issues that could affect the performance of the oil cooling system.

Troubleshooting Common Issues

Common problems with oil cooler tubes can include leaks, blockages, or reduced efficiency. Troubleshooting these issues may involve inspecting the tube for signs of wear or damage, checking the connections for tightness, and ensuring that the flow of oil is not obstructed. Addressing these problems promptly can help maintain the effectiveness of the oil cooling system.

Maintenance Tips

Regular maintenance of the 3916285 is important for ensuring continued optimal performance. This includes periodic inspections for signs of wear or corrosion, cleaning the tube to remove any buildup that could impede heat transfer, and replacing the tube if it shows significant signs of degradation. Adhering to a maintenance schedule can help prevent unexpected failures and extend the life of the engine system.

Cummins: A Brief Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its range of diesel engines and related technologies. With a history of innovation and a commitment to quality, Cummins has built a reputation for producing reliable and high-performance engine components. The company’s product range includes a variety of parts and systems designed to enhance the efficiency and durability of commercial vehicles.

Compatibility of Cummins Oil Cooler Tube Part 3916285

This part is designed to fit seamlessly with several engine models, ensuring optimal performance and longevity. It is engineered to meet the stringent requirements of high-performance engines, providing efficient cooling and maintaining the integrity of the oil system.

6B5.9 Engine

The 6B5.9 engine is one of the models that benefit from the installation of the Cummins Oil Cooler Tube part 3916285. This part is specifically tailored to fit the unique design and cooling needs of the 6B5.9 engine, ensuring that the oil remains at the optimal temperature for efficient engine operation.

ISB CM550 Engine

Similarly, the ISB CM550 engine is another model that is compatible with the Cummins Oil Cooler Tube part 3916285. This part is engineered to fit the ISB CM550 engine’s specific requirements, ensuring that the oil cooler system operates efficiently and effectively. The design of the part ensures that it integrates smoothly with the engine’s architecture, providing reliable performance and durability.

Grouping of Compatible Engines

The Cummins Oil Cooler Tube part 3916285 is designed to fit a range of Cummins engines, including but not limited to the 6B5.9 and ISB CM550 models. This part is a critical component in maintaining the cooling efficiency of these engines, ensuring that they operate at peak performance levels. The compatibility of this part with multiple engine models underscores its versatility and importance in the engine’s overall cooling system.

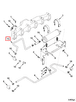

Role of Part 3916285 Oil Cooler Tube in Engine Systems

The Oil Cooler Tube is an essential component in the thermal management of engine systems, particularly in relation to the cooler, torque converter oil, and torque converter cooler.

In the context of the cooler, the oil cooler tube facilitates the circulation of engine oil through the cooler. This process is vital for dissipating heat generated by the engine, ensuring that the oil remains within optimal temperature ranges for efficient lubrication and performance.

When considering the torque converter oil, the oil cooler tube plays a significant role in maintaining the viscosity and temperature of the oil. Proper temperature regulation is necessary for the torque converter to function effectively, as it relies on the oil’s specific properties to transmit power from the engine to the transmission.

In relation to the torque converter cooler, the oil cooler tube ensures a consistent flow of oil through the cooler. This helps in removing excess heat from the torque converter, which is generated during operation. Effective cooling prolongs the lifespan of the torque converter and enhances the overall reliability of the transmission system.

Overall, the Part 3916285 Oil Cooler Tube is integral to the efficient operation and longevity of engine and transmission components by ensuring proper thermal management.

Conclusion

The Cummins 3916285 Oil Cooler Tube is a vital component for maintaining the efficiency and reliability of commercial truck engines. By ensuring optimal oil temperature, this part contributes to engine longevity, reduces maintenance costs, and enhances overall vehicle performance. Regular maintenance and proper installation are crucial for maximizing the benefits of this essential engine component.

-

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ -

Dixon, J. (2014). Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning.

↩ -

Bennett, S. (2012). Modern Diesel Technology: Light Duty Diesels. Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.