3923616

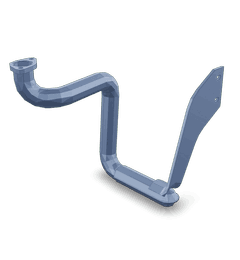

Oil Suction Connection

Cummins®

IN STOCK

3 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Oil Suction Connection 3923616, manufactured by Cummins, is a component designed for use in heavy-duty truck engines. Cummins, a well-established name in the engine manufacturing industry, produces a range of parts that contribute to the efficient operation and longevity of engines. This Cummins part is significant within this context as it plays a role in the engine’s lubrication system, ensuring optimal performance and durability.

Basic Concepts of Oil Suction Connections

An oil suction connection is a component within an engine’s lubrication system that facilitates the drawing of oil from the oil pan or sump. This process is vital for maintaining a continuous supply of lubricant to the engine’s moving parts, which helps reduce friction, wear, and heat generation. Effective lubrication is key to the overall performance and longevity of an engine, as it ensures that components operate smoothly and efficiently 1.

Purpose of the Oil Suction Connection 3923616

The Oil Suction Connection 3923616 is specifically designed to play a role in the oil circulation process within a truck engine. It connects to the oil pump, allowing for the efficient suction of oil from the sump. This connection ensures that the oil pump can draw oil consistently, which is necessary for maintaining proper lubrication throughout the engine. Its design and placement are critical for the effective operation of the lubrication system.

Key Features

The Oil Suction Connection 3923616 is characterized by several features that enhance its functionality and reliability. These include its material composition, which is selected for durability and resistance to the harsh conditions within an engine. The construction of the connection is designed to ensure a secure fit and seal, preventing leaks and ensuring efficient oil suction. Additionally, any unique design aspects, such as threading or sealing mechanisms, contribute to its performance and ease of installation.

Benefits

The advantages of using the Oil Suction Connection 3923616 include improved engine performance due to efficient lubrication, enhanced durability of engine components through reduced wear, and potential cost savings for fleet operators. By ensuring a consistent supply of oil to the engine, this component helps maintain optimal operating conditions, which can lead to extended engine life and reduced maintenance needs 2.

Installation Process

Installing the Oil Suction Connection 3923616 requires following a series of steps to ensure optimal performance and longevity. Best practices include cleaning the installation area to prevent contamination, using the correct tools to avoid damage, and ensuring a tight seal to prevent leaks. Specific considerations may include the orientation of the connection and the use of recommended sealants or gaskets.

Troubleshooting and Maintenance

Common issues associated with oil suction connections can include leaks, blockages, or damage to the connection itself. Diagnosing these problems may involve visual inspection, pressure testing, or analyzing engine performance data. Maintenance tips to prevent failures and extend the lifespan of the component include regular inspection for signs of wear or damage, ensuring proper installation, and following manufacturer recommendations for maintenance intervals and procedures.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the heavy-duty truck and engine manufacturing industry. The company’s product range includes a variety of engines and components designed to meet the demanding requirements of commercial and industrial applications.

Compatibility of Oil Suction Connection Part 3923616 with Cummins Engines

The Oil Suction Connection part 3923616, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is crucial for maintaining proper oil flow within the engine, ensuring that the lubrication system operates efficiently.

ISC Series Engines

The ISC series engines that are compatible with the Oil Suction Connection part 3923616 include:

- ISC CM2150

- ISC CM554

- ISC CM850

- ISC8.3 CM2250

These engines are known for their robust performance and reliability, often used in heavy-duty applications.

ISL Series Engines

The ISL series engines that are compatible with this part include:

- ISL CM2150

- ISL G CM2180

- ISL9 CM2150 SN

- ISL9 CM2250

The ISL series is recognized for its high power output and efficiency, making it a popular choice for various industrial and commercial applications.

QSC Series Engines

The QSC series engines compatible with the Oil Suction Connection part 3923616 are:

- QSC8.3 CM554

- QSC8.3 CM850 (CM2850)

These engines are designed for applications requiring high performance and reliability, often used in construction and agricultural machinery.

QSL Series Engines

The QSL series engines that fit this part include:

- QSL9 CM2250

- QSL9 CM2350 L102

- QSL9 CM850 (CM2850)

- QSL9.3 CM2880 L113

The QSL series is engineered for demanding applications, providing excellent power and efficiency.

L Series Engines

The L series engines that are compatible with the Oil Suction Connection part 3923616 include:

- L8.9

- L8.9 L121

- L8.9G CMOH2.0 L125B

These engines are known for their durability and are often used in applications requiring consistent performance.

C Series Engines

The C series engines compatible with this part include:

- 6C8.3

- C GAS PLUS CM556

- C8.3 G

These engines are designed for applications that require a balance of power and efficiency, often used in various industrial settings.

Role of Part 3923616 Oil Suction Connection in Engine Systems

The Oil Suction Connection 3923616 is integral to the efficient operation of engine systems, particularly in the context of the oil pan and oil circulation. This component serves as a vital interface between the oil pan and the engine’s lubrication system.

Integration with the Oil Pan

The oil suction connection is designed to fit securely into the oil pan, which is the reservoir for the engine’s lubricant. Its primary function is to draw oil from the pan and direct it towards the oil pump. This ensures a continuous supply of oil is available for the pump to circulate throughout the engine, maintaining proper lubrication of moving parts.

Interaction with the Oil Pump

Once the oil is suctioned from the pan via the 3923616 connection, it is transported to the oil pump. The pump then pressurizes the oil and distributes it to various engine components, such as the crankshaft, camshaft, and valve train. This process is essential for reducing friction, dissipating heat, and preventing wear on these components 3.

Ensuring Efficient Oil Circulation

The design of the 3923616 oil suction connection is optimized to minimize turbulence and ensure a smooth flow of oil from the pan to the pump. This efficiency in oil circulation is key to maintaining the engine’s performance and longevity. Proper lubrication reduces the risk of overheating and component failure, contributing to the overall reliability of the engine system.

Maintenance and Inspection

Regular inspection of the 3923616 oil suction connection is recommended to ensure it remains in good condition. Any signs of wear, leaks, or damage should be addressed promptly to prevent potential issues with oil supply and engine lubrication.

Conclusion

The Oil Suction Connection 3923616 plays a significant role in the lubrication system of heavy-duty truck engines, ensuring efficient oil circulation and maintaining optimal engine performance. Its compatibility with a wide range of Cummins engines underscores its importance in the industry. Regular maintenance and proper installation are essential to maximize the benefits of this component.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.