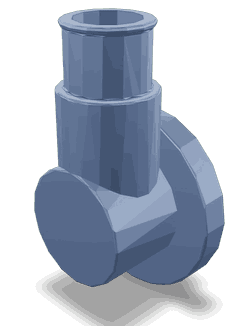

3924595

Oil Filler Connection

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3924595 Oil Filler Connection is a vital component for heavy-duty truck engines, designed to facilitate the addition of oil to the engine. This ensures the lubrication system operates effectively, maintaining engine performance and longevity through convenient and secure oil top-ups.

Purpose and Function

This part serves a critical role in the lubrication system by providing a point of access for adding oil to the engine. It is engineered to maintain proper oil levels, which are essential for reducing friction between moving parts, cooling the engine, and cleaning internal components. By ensuring that oil is added correctly and securely, this component helps preserve the engine’s efficiency and durability 1.

Key Features

The Cummins 3924595 is constructed from high-quality materials that resist corrosion and wear, ensuring longevity in demanding environments. It includes a sealing mechanism that prevents oil leaks, maintaining the integrity of the lubrication system. Unique design elements may include a threaded cap for secure closure and a spout designed to guide oil flow directly into the engine 2.

Benefits

The Oil Filler Connection offers several advantages that contribute to engine maintenance and performance. Its design allows for ease of use, making oil changes and top-ups straightforward for operators. The reliability of the connection ensures that oil levels are maintained accurately, which is crucial for engine health. Additionally, by facilitating proper lubrication, this component plays a role in extending engine longevity and improving overall truck performance. These benefits impact maintenance routines by reducing the frequency of oil-related issues and enhancing the efficiency of service operations 3.

Installation and Compatibility

Proper installation of the Oil Filler Connection is crucial for its effective function. Guidelines for installation should be followed to ensure that the connection is securely fitted and properly sealed. Compatibility with specific engine models is important, and it is advisable to consult manufacturer specifications to ensure the correct fit and function. Any specific requirements or considerations for installation, such as torque settings or the need for sealant, should be adhered to for optimal performance 4.

Maintenance and Troubleshooting

Routine maintenance of the Oil Filler Connection is important for its longevity and efficiency. This may include regular checks for signs of wear or damage, ensuring the sealing mechanism remains intact, and cleaning the area around the connection to prevent contamination. Common issues that may arise include leaks or difficulty in securing the cap, which can often be addressed by inspecting and replacing worn components or ensuring proper installation techniques are used.

Safety Considerations

When working with the Oil Filler Connection, it is important to observe safety practices and precautions. This includes ensuring that the engine is cool before attempting any maintenance or oil addition to avoid burns from hot surfaces. Improper use or maintenance of the connection can lead to oil leaks, which not only affect engine performance but can also pose safety risks. It is crucial to follow manufacturer guidelines for use and maintenance to ensure both engine and personal safety.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established itself as a key player in the automotive industry, particularly in the production of diesel engines and components. The company’s commitment to innovation, quality, and customer satisfaction has made it a trusted name in the industry, providing solutions that meet the demanding requirements of heavy-duty applications.

Cummins Engine Compatibility with Oil Filler Connection Part 3924595

The Oil Filler Connection part 3924595, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is integral for maintaining the proper oil levels and ensuring the engine operates smoothly. Below is a detailed breakdown of the engines that are compatible with this specific part:

6C Series Engines

- 6C8.3

- 6C8.3 G

B Series Engines

- B5.9

- B5.9 G

- B5.9 GAS PLUS CM556

C Series Engines

- C GAS PLUS CM556

- L GAS PLUS CM556

ISB Series Engines

- ISB CM550

ISC Series Engines

- ISC CM2150

- ISC CM554

- ISC CM850

ISL Series Engines

- ISL CM2150

- ISL CM554

- ISL G CM2180

- ISL9 CM2150 SN

- ISL9 CM2250

L Series Engines

- L8.9

- L9 CM2670 L128B

QSC Series Engines

- QSC8.3 CM554

- QSC8.3 CM850 (CM2850)

QSL Series Engines

- QSL8.9 CM2150 L141

- QSL9 CM2350 L102

- QSL9 CM554

This part is essential for the oil management system of these engines, ensuring that the oil is correctly filled and maintained, which is crucial for the longevity and performance of the engine.

Role of Part 3924595 Oil Filler Connection in Engine Systems

The 3924595 Oil Filler Connection is a critical component in the lubrication system of an engine, facilitating the process of adding oil to the system. Its integration with various engine components ensures efficient oil distribution and maintenance of optimal lubrication levels.

Integration with Engine Components

-

Arrangement: The Oil Filler Connection is strategically positioned within the engine’s arrangement to allow easy access for oil addition. This placement is typically near the top of the engine, ensuring that oil can be gravity-fed into the system.

-

Oil Fill: Directly connected to the oil fill system, this component acts as the primary point for introducing oil into the engine. It is designed to align with the oil fill cap, allowing for a secure and leak-free connection during the oil addition process.

-

Cover: The Oil Filler Connection interfaces with the engine cover, which protects internal components. It is engineered to fit snugly within the cover, ensuring that oil does not leak out during operation. The cover also provides structural support to the connection, enhancing its durability.

-

Cylinder Block: Connected to the cylinder block, the Oil Filler Connection plays a role in directing oil to the various lubrication points within the block. This ensures that critical moving parts, such as pistons and bearings, receive adequate lubrication.

-

Hand Hole: Often located near a hand hole, the Oil Filler Connection allows mechanics easy access for maintenance tasks. The hand hole provides a convenient entry point for inspections and adjustments, enhancing the overall serviceability of the engine.

By seamlessly integrating with these components, the 3924595 Oil Filler Connection contributes to the efficient operation and maintenance of the engine’s lubrication system.

Conclusion

The Cummins 3924595 Oil Filler Connection is an essential component for maintaining the lubrication system in heavy-duty truck engines. Its design and features ensure efficient oil addition, maintenance of proper oil levels, and overall engine performance. Proper installation, maintenance, and adherence to safety guidelines are crucial for maximizing the benefits of this component.

-

{ title : Diesel Mechanics, First Edition , author : Frank Sander , publisher : Global Media , date : 2007 }

↩ -

{ title : Modern Diesel Technology Light Duty Diesels , author : Sean Bennett , publisher : Cengage Learning , date : 2012 }

↩ -

{ title : Diesel Engines , author : A. J. Wharton , publisher : Butterworth-Heinemann Ltd , date : 1991 }

↩ -

{ engine : B4.0 CM2620 B154B , title : Service Manual (5579476) }

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.