This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Lubricating Oil Drain Tube 3924871, manufactured by Cummins, is a critical component for maintaining heavy-duty trucks. Cummins, a prominent figure in the automotive industry, offers a variety of components that enhance the efficiency and reliability of heavy-duty vehicles. This part is essential for facilitating the drainage of lubricating oil during maintenance routines, contributing to the overall health and performance of the truck’s engine 1.

Basic Concepts of Lubricating Oil Drain Tubes

A lubricating oil drain tube is a vital component within the engine system, designed to allow for the removal of used oil during maintenance. Regular oil changes are crucial for engine health, as they help remove contaminants and ensure smooth operation. The drain tube provides a safe and efficient pathway for oil to exit the engine, playing a significant role in this process 2.

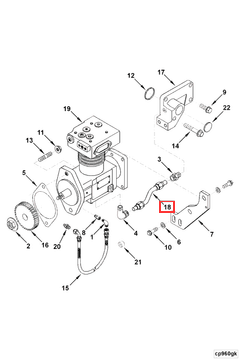

Role of the 3924871 Lubricating Oil Drain Tube in Truck Operation

The 3924871 Lubricating Oil Drain Tube is integral to the operation of a truck, especially during maintenance procedures. It is designed to fit seamlessly into the truck’s engine system, allowing for efficient oil drainage. This ensures that the maintenance process is straightforward and minimizes the risk of spills or contamination 3.

Key Features of the 3924871 Lubricating Oil Drain Tube

The 3924871 Lubricating Oil Drain Tube is characterized by its robust design and high-quality materials. It is engineered to withstand the pressures and temperatures associated with heavy-duty truck engines. The tube’s design includes features that enhance its performance and durability, ensuring reliable operation under various conditions 4.

Benefits of Using the 3924871 Lubricating Oil Drain Tube

Utilizing the 3924871 Lubricating Oil Drain Tube offers several advantages. It contributes to improved engine longevity by ensuring that oil changes are conducted efficiently. The tube’s design also makes maintenance procedures easier, reducing the time and effort required for oil changes. Additionally, its reliable performance under different operating conditions ensures that trucks remain in optimal condition 5.

Installation and Usage Guidelines

To ensure the optimal functionality and safety of the 3924871 Lubricating Oil Drain Tube, it is important to follow proper installation and usage guidelines. This includes ensuring that the tube is correctly positioned within the engine system and that all connections are secure. Regular inspections should also be conducted to verify that the tube remains in good condition 6.

Troubleshooting Common Issues

Frequent problems associated with lubricating oil drain tubes can include leaks or blockages. To address these issues, it is recommended to inspect the tube and its connections for any signs of wear or damage. Cleaning the tube and ensuring that it is free from obstructions can also help resolve common problems 7.

Maintenance Tips

To prolong the service life of the 3924871 Lubricating Oil Drain Tube and ensure consistent performance, regular maintenance is advised. This includes cleaning the tube to remove any buildup and inspecting it for signs of wear or damage. Following these routines can help maintain the tube’s efficiency and reliability 8.

About Cummins

Cummins Inc. is a leader in the automotive industry, known for its innovative products and commitment to quality. The company offers a wide range of components for heavy-duty trucks, including engines, filtration systems, and aftermarket parts. Cummins’ dedication to innovation and excellence has established it as a trusted name in the industry 9.

Conclusion

The 3924871 Lubricating Oil Drain Tube by Cummins is a vital component for the maintenance and operation of heavy-duty trucks. Its robust design, ease of use, and reliable performance make it an essential part of the engine system. Regular maintenance and proper usage of this part ensure the longevity and efficiency of the truck’s engine, contributing to the overall performance and reliability of the vehicle.

-

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

Stiesch, G. (2003). Modeling Engine Spray and Combustion Processes. Springer Verlag.

↩ -

Kluczyk, B. (2008). How to Rebuild Any Automotive Engine. CarTech.

↩ -

Hilgers, M. (2023). Entire Vehicle: Second Edition. Springer Nature.

↩ -

Cummins Inc. (n.d.). Owners Manual for QSF2.8 CM2880 F108, Bulletin Number 4332748.

↩ -

Cummins Inc. (n.d.). Owners Manual for QSF2.8 CM2880 F108, Bulletin Number 4332748.

↩ -

Cummins Inc. (n.d.). Owners Manual for QSF2.8 CM2880 F108, Bulletin Number 4332748.

↩ -

Cummins Inc. (n.d.). Owners Manual for QSF2.8 CM2880 F108, Bulletin Number 4332748.

↩ -

Cummins Inc. (n.d.). Owners Manual for QSF2.8 CM2880 F108, Bulletin Number 4332748.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.