This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

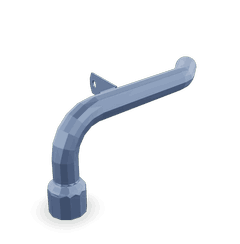

The Lubricating Oil Drain Tube, identified by Cummins Part #3925524, is a component integral to the maintenance regimen of heavy-duty trucks. Manufactured by Cummins Inc., a leader in the automotive industry, this part facilitates the efficient drainage of used oil from the engine, ensuring that the lubrication system operates within optimal parameters. Proper maintenance of the lubrication system is vital for the longevity and performance of heavy-duty engines, making the Lubricating Oil Drain Tube a significant element in routine maintenance procedures 1.

Function and Operation

The Lubricating Oil Drain Tube operates by providing a conduit for the removal of used oil from the engine’s lubrication system. During maintenance, the tube allows for the controlled and efficient drainage of oil, which is a necessary step in preserving engine health. By enabling the straightforward removal of old oil, the tube plays a role in facilitating the replacement with fresh lubricant, which is crucial for reducing friction, wear, and maintaining engine efficiency 2.

Key Features

The Lubricating Oil Drain Tube is designed with specific features that enhance its performance and durability. It is constructed from materials that resist corrosion and wear, ensuring longevity even in the demanding environments typical of heavy-duty applications. The tube’s threading specifications are tailored to fit securely within the engine’s oil pan, preventing leaks and ensuring a tight seal. Additionally, the design may incorporate features such as a built-in gasket or O-ring to further enhance the seal and prevent oil leakage during operation 3.

Benefits

The advantages of using the Lubricating Oil Drain Tube include efficient oil drainage, which reduces the time required for maintenance procedures. This efficiency contributes to minimizing downtime for heavy-duty trucks, which is beneficial for fleet operations. Moreover, by ensuring that the engine is properly lubricated with fresh oil, the tube plays a role in promoting engine longevity and performance. Proper lubrication management is key to reducing friction and wear within the engine, leading to more reliable operation over time 4.

Installation and Usage

Correct installation of the Lubricating Oil Drain Tube is vital for its optimal performance. The process involves ensuring that the tube is properly aligned with the oil pan’s drain plug opening, followed by securing it in place according to the manufacturer’s specifications. It is important to follow best practices, such as using the appropriate torque settings for tightening, to prevent over-tightening, which could damage the tube or the oil pan. Safety considerations, including wearing protective gear and ensuring the engine is cool before beginning work, should be observed throughout the installation process 5.

Maintenance and Troubleshooting

Maintaining the Lubricating Oil Drain Tube involves regular inspection for signs of wear, corrosion, or damage. Cleaning the tube and its surrounding area can prevent the accumulation of debris that might obstruct oil flow or cause leaks. Troubleshooting common issues, such as leaks or blockages, may involve checking the tube’s seal, ensuring it is properly seated, and replacing any worn gaskets or O-rings as necessary. Regular maintenance of the tube contributes to the overall efficiency and reliability of the engine’s lubrication system 6.

Safety Considerations

When handling and working with the Lubricating Oil Drain Tube, it is important to observe safety protocols to prevent accidents. This includes ensuring that the engine is turned off and has sufficiently cooled before beginning any maintenance work. Wearing appropriate personal protective equipment, such as gloves and safety glasses, is recommended to protect against hot oil and other potential hazards. Additionally, working in a well-ventilated area and disposing of used oil according to environmental regulations are crucial safety practices 7.

Environmental Impact

The disposal and recycling of used lubricating oil drained through the Lubricating Oil Drain Tube are important environmental considerations. Responsible waste management practices, such as recycling used oil and disposing of oil filters according to local regulations, help minimize the environmental impact of heavy-duty truck maintenance. Cummins and other industry leaders advocate for the recycling of used oil to reduce waste and promote sustainability in the automotive sector 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is committed to innovation, quality, and customer satisfaction. The company’s product portfolio includes a wide range of engines and components for on-highway, off-highway, and stationary applications, demonstrating its versatility and expertise in the automotive industry. Cummins’ commitment to quality and innovation is evident in its comprehensive range of parts and services designed to enhance the performance, efficiency, and reliability of heavy-duty engines 9.

Cummins Lubricating Oil Drain Tube (Part 3925524) Compatibility

The Cummins Lubricating Oil Drain Tube, identified by part number 3925524, is designed to fit a variety of Cummins engines. This part is integral to the oil management system, facilitating the efficient drainage of used oil from the engine’s sump. Below is a detailed look at its compatibility with specific Cummins engine models:

6C8.3 and C8.3 G Engines

The 6C8.3 and C8.3 G engines are part of Cummins’ lineup of medium-duty diesel engines. These engines are known for their robust performance and reliability, often used in various industrial and commercial applications. The lubricating oil drain tube is specifically engineered to fit these engines, ensuring that the oil is effectively drained and replaced during maintenance cycles.

ISC CM554 and ISC CM850 Engines

The ISC CM554 and ISC CM850 engines are part of Cummins’ heavy-duty diesel engine series. These engines are designed for high-performance applications, including heavy trucks and industrial machinery. The lubricating oil drain tube is a critical component for these engines, providing a reliable means to remove used oil and maintain optimal engine health.

ISL CM554 and ISL9 CM2150 SN Engines

The ISL CM554 and ISL9 CM2150 SN engines are also part of Cummins’ heavy-duty diesel engine family. These engines are renowned for their power and efficiency, often used in the most demanding applications. The lubricating oil drain tube is essential for these engines, ensuring that the oil is effectively drained and replaced, which is crucial for maintaining engine performance and longevity.

In summary, the Cummins Lubricating Oil Drain Tube (Part 3925524) is compatible with a range of Cummins engines, including the 6C8.3, C8.3 G, ISC CM554, ISC CM850, ISL CM554, and ISL9 CM2150 SN models. This part plays a vital role in the oil management system of these engines, ensuring efficient oil drainage and contributing to overall engine reliability and performance.

Role of Part 3925524 Lubricating Oil Drain Tube in Engine Systems

The lubricating oil drain tube, part number 3925524, is an essential component in the maintenance and operation of engine systems. It facilitates the efficient draining of used lubricating oil from the engine, ensuring that the oil change process is smooth and effective.

Integration with Key Engine Components

Cylinder Block

The cylinder block houses the engine’s cylinders, pistons, and other critical components. The lubricating oil drain tube is typically attached near the bottom of the cylinder block, allowing for the straightforward removal of old oil. This placement ensures that the oil, which has circulated through the engine and collected contaminants, can be easily drained away, maintaining the engine’s performance and longevity.

Oil Fill and Cover

The oil fill and cover components are responsible for housing the engine’s oil supply. After the old oil is drained via the lubricating oil drain tube, fresh oil is added through the oil fill port. The cover ensures that the oil remains contained within the system. The efficient draining process facilitated by the drain tube ensures that the new oil added will be free from contaminants, optimizing lubrication and reducing wear on engine parts.

Arrangement and Mounting

The arrangement and mounting of the lubricating oil drain tube are designed to align with the engine’s overall structure. Proper mounting ensures that the tube is securely in place, preventing leaks and ensuring that the oil drains completely. This integration is vital for maintaining the engine’s structural integrity and operational efficiency.

Alternator

While the alternator is not directly connected to the oil drain process, its proximity to the cylinder block and other engine components means that the efficient operation of the lubricating oil drain tube indirectly supports the alternator’s function. By ensuring that the engine runs smoothly with proper lubrication, the alternator can operate more efficiently, contributing to the overall performance of the engine system.

In summary, the lubricating oil drain tube, part number 3925524, plays a significant role in the maintenance and efficiency of engine systems by ensuring that old, contaminated oil is effectively removed, allowing for the introduction of fresh lubricants that keep the engine running smoothly.

Conclusion

The Lubricating Oil Drain Tube, part number 3925524, is a critical component in the maintenance and operation of heavy-duty engines. Its role in facilitating the efficient drainage of used oil ensures that engines remain lubricated with fresh oil, reducing friction, wear, and promoting longevity. Proper installation, maintenance, and adherence to safety protocols are essential for maximizing the benefits of this part. Additionally, responsible environmental practices in the disposal and recycling of used oil contribute to sustainability in the automotive sector. Cummins Inc.’s commitment to quality and innovation is reflected in the design and functionality of this part, ensuring that it meets the demanding requirements of heavy-duty applications.

-

Crolla, David. Crolla Encyclopedia. Wiley, 2015.

↩ -

Hilgers, Michael. The Diesel Engine Second Edition. Springer Nature, 2023.

↩ -

Pulkrabek, Willard W. Engineering Fundamentals of the Internal Combustion Engine. Pearson Education, 2014.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 4367221, 2023.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 4367221, 2023.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 4367221, 2023.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 4367221, 2023.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 4367221, 2023.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 4367221, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.