This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3929106 Oil Seal is a vital component in the efficient operation of commercial trucks. It maintains the integrity of the engine or transmission system by preventing lubricant leakage and blocking contaminants. Understanding its function and significance is essential for maintaining the performance and longevity of truck systems.

Basic Concepts of Oil Seals

An oil seal, also known as a rotary shaft seal, is a mechanical device used in machinery to prevent lubricant leakage and keep out contaminants. It creates a barrier between the rotating shaft and the stationary housing, which is crucial for maintaining lubrication within the system and protecting internal components from dirt and debris 1.

Purpose of the Cummins 3929106 Oil Seal

The Cummins 3929106 Oil Seal is positioned within the engine or transmission of a truck. Its function is to maintain system integrity by ensuring that lubricants remain within the system and contaminants are kept out. This seal plays a role in preserving the efficiency and reliability of the truck’s engine or transmission 2.

Key Features

The Cummins 3929106 Oil Seal is characterized by its material composition, typically made from durable elastomers, and its design elements, which include a lip that contacts the shaft to create a seal. These features contribute to its performance and durability, allowing it to withstand the operational stresses within a truck’s engine or transmission 3.

Benefits

The use of the Cummins 3929106 Oil Seal offers several advantages, including improved efficiency of the engine or transmission, extended lifespan of components due to better lubrication management, and reduced maintenance requirements by minimizing the risk of lubricant loss and contamination 4.

Installation Considerations

Proper installation of the Cummins 3929106 Oil Seal is vital for its effectiveness. This process may require specific tools and techniques to ensure a secure and effective fit. Attention to detail during installation helps prevent future issues related to seal failure 5.

Troubleshooting Common Issues

Common problems with oil seals, such as leaks or wear, can arise due to various factors including improper installation, excessive wear, or contamination. Troubleshooting these issues involves a systematic approach to diagnose the root cause and apply the appropriate corrective measures 6.

Maintenance Tips

To prolong the life of the Cummins 3929106 Oil Seal, routine maintenance practices are recommended. These include regular inspection intervals to check for signs of wear or damage, cleaning procedures to remove any contaminants that may affect the seal’s performance, and following replacement guidelines to ensure the seal remains effective over time 7.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality and reliability, which is reflected in its wide range of products, including the 3929106 Oil Seal 8.

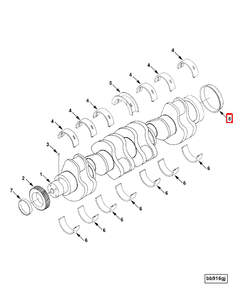

Components of Cummins Oil Seal Kit 3929106

The Cummins Oil Seal Kit 3929106 is a comprehensive assembly designed to facilitate the replacement and maintenance of oil seals in various engine applications. This kit includes critical components that work together to ensure the effective sealing of oil within the engine, preventing leaks and maintaining optimal performance.

Wear Sleeve (3925532)

The wear sleeve is a crucial component in the oil seal kit. It is designed to provide a smooth surface for the oil seal to ride against. This reduces friction and wear on the seal, extending its lifespan and ensuring a tight seal is maintained. The wear sleeve is typically made from a durable material that can withstand the high temperatures and pressures within an engine environment.

Oil Seal (3927871)

The oil seal itself is the primary component responsible for preventing oil leakage from the engine. It is positioned between moving parts and stationary components, creating a barrier that keeps oil contained within the engine. The oil seal is usually made from materials like rubber or synthetic compounds that can flex and conform to the surfaces they contact, ensuring a consistent seal even under dynamic conditions.

These components, when assembled correctly, form a reliable system that maintains the integrity of the engine’s lubrication system. The wear sleeve supports the oil seal, allowing it to function efficiently, while the oil seal performs the critical task of containing oil within the engine. Together, they ensure that the engine operates smoothly and efficiently, with minimal risk of oil leaks.

Conclusion

The Cummins 3929106 Oil Seal plays a significant role in the maintenance and efficiency of commercial truck engines and transmissions. Understanding its function, proper installation, and maintenance can lead to improved performance and longevity of the vehicle’s systems. Cummins’ commitment to quality is evident in the design and reliability of this part, making it a crucial component for truck operators and maintenance professionals.

-

Crolla, David. Crolla Encyclopedia. Wiley, 2015.

↩ -

Hu, Haoran, Simon J Baseley, and Xubin Song. Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International, 2021.

↩ -

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines. McGraw-Hill, 2008.

↩ -

Asef, Pedram, Sanjeevikumar Padmanaban, and Andrew Lapthorn. Modern Automotive Electrical Systems. Wiley, 2022.

↩ -

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines. McGraw-Hill, 2008.

↩ -

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines. McGraw-Hill, 2008.

↩ -

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines. McGraw-Hill, 2008.

↩ -

Hu, Haoran, Simon J Baseley, and Xubin Song. Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International, 2021.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.