This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

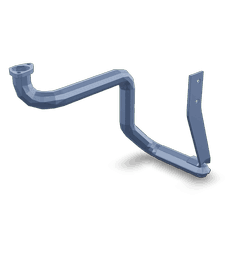

The Oil Suction Connection 3931979 by Cummins is a component designed for use in heavy-duty trucks. Its purpose is to facilitate the efficient suction of oil from the oil pan to the engine’s lubrication system. This part plays a role in ensuring that the engine receives a consistent supply of oil, which is vital for its operation and longevity.

Basic Concepts of Oil Suction Connection

An oil suction connection is a component within the lubrication system of a truck engine that allows for the drawing of oil from the oil pan. This process is fundamental to the lubrication system, as it ensures that oil is circulated throughout the engine to reduce friction between moving parts, cool the engine, and remove contaminants. The proper functioning of the oil suction connection is important for maintaining engine health, as it directly affects the efficiency and reliability of the lubrication process 1.

Purpose and Role in Truck Operation

The 3931979 Oil Suction Connection serves a specific purpose within the truck’s lubrication system by enabling the efficient transfer of oil from the oil pan to the engine. This part contributes to the engine’s operation by ensuring that oil is consistently circulated, which helps in reducing wear on engine components, maintaining optimal operating temperatures, and enhancing the overall performance and durability of the engine 2.

Key Features

The 3931979 Oil Suction Connection is characterized by several key features that enhance its performance and durability. These include a robust design that is resistant to the high pressures and temperatures within the engine compartment, the use of high-quality materials that ensure longevity and reliability, and unique attributes such as precise engineering to ensure a secure fit and efficient oil flow. These features collectively contribute to the part’s ability to perform under demanding conditions.

Benefits

Utilizing the 3931979 Oil Suction Connection offers several benefits. It contributes to improved engine lubrication by ensuring a consistent and efficient oil flow, which is vital for reducing engine wear and maintaining performance. The part’s durable construction and precise design also enhance engine durability, potentially contributing to fuel efficiency by ensuring that the engine operates smoothly and efficiently 3. Additionally, the reliable performance of this component can lead to reduced maintenance costs over time.

Installation and Compatibility

Proper installation of the 3931979 Oil Suction Connection is important for ensuring its effective operation. Guidelines for installation include following manufacturer recommendations for torque settings and ensuring a secure fit to prevent oil leaks. This part is designed to be compatible with various Cummins engine models, ensuring that it can be integrated into different truck systems without issues.

Troubleshooting and Maintenance

Common issues associated with oil suction connections may include oil leaks or inefficient oil flow, which can be addressed through regular inspection and maintenance. Troubleshooting steps may involve checking for proper installation, ensuring there are no obstructions in the oil path, and verifying that all connections are secure. Maintenance tips to ensure the longevity and optimal performance of the 3931979 Oil Suction Connection include regular inspection for wear or damage, cleaning the area around the connection to prevent contamination, and following the manufacturer’s recommendations for maintenance intervals.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel engines and related technologies. With a history of innovation and a commitment to quality, Cummins has established itself as a trusted name in the automotive industry. The company’s product range includes engines, filtration systems, and other components designed to meet the demanding requirements of heavy-duty applications. Cummins’ dedication to innovation and quality is evident in its continuous efforts to improve product performance, efficiency, and reliability.

Cummins Engine Part 3931979: Oil Suction Connection

The Cummins part 3931979, identified as an Oil Suction Connection, is a component in the lubrication system of certain Cummins engines. This part is designed to facilitate the flow of oil from the oil pan to the oil pump, ensuring that the engine receives a consistent and adequate supply of lubrication.

Compatibility with Cummins Engines

The Oil Suction Connection part 3931979 is compatible with the following Cummins engine models:

- 6C8.3

- QSC8.3 CM554

- QSC8.3 CM850 (CM2850)

Grouping of Compatible Engines

The engines listed above can be grouped based on their series and configurations. The 6C8.3 is a standalone model, while the QSC8.3 CM554 and QSC8.3 CM850 (CM2850) are part of the QSC8.3 series. The QSC8.3 CM850 (CM2850) is essentially a higher displacement variant of the QSC8.3 CM554, offering increased power output.

Installation and Function

The installation of the Oil Suction Connection part 3931979 is crucial for maintaining the integrity of the engine’s lubrication system. This part is typically located at the bottom of the engine, where it connects to the oil pan. It ensures that oil is drawn efficiently into the oil pump, which then distributes it throughout the engine to lubricate moving parts, reduce friction, and dissipate heat.

Proper installation and maintenance of this component are essential to prevent oil starvation, which can lead to engine failure. Regular inspection and replacement of the Oil Suction Connection, as per the manufacturer’s recommendations, are advised to ensure optimal engine performance and longevity.

Role of Part 3931979 Oil Suction Connection in Engine Systems

The part 3931979 Oil Suction Connection is an integral component in the lubrication system of an engine, facilitating the efficient circulation of oil to various engine parts. This component is strategically positioned to interface with the oil pan and the oil pump.

Interaction with the Oil Pan

The oil pan serves as the reservoir for the engine’s lubrication system, holding a significant volume of oil. The 3931979 Oil Suction Connection is designed to fit securely into the oil pan, creating a sealed pathway for oil to be drawn from the pan. This connection ensures that the oil is suctioned efficiently, minimizing the risk of air ingestion which could lead to cavitation in the oil pump.

Connection to the Oil Pump

Once the oil is suctioned from the oil pan via the 3931979 Oil Suction Connection, it is directed towards the oil pump. The oil pump is responsible for pressurizing the oil and distributing it throughout the engine to lubricate moving parts, reduce friction, and dissipate heat. The secure fitting of the 3931979 Oil Suction Connection to the oil pump inlet ensures a consistent flow of oil, which is essential for maintaining optimal engine performance and longevity.

Ensuring System Integrity

The 3931979 Oil Suction Connection plays a significant role in maintaining the integrity of the lubrication system. By providing a reliable connection between the oil pan and the oil pump, it helps to ensure that the engine receives a steady supply of oil. This consistent lubrication is vital for the protection of engine components such as bearings, pistons, and camshafts, which are subject to high levels of stress and friction during operation.

Conclusion

In summary, the 3931979 Oil Suction Connection is a key component in the engine’s lubrication system, facilitating the efficient transfer of oil from the oil pan to the oil pump. Its proper installation and maintenance are essential for the overall health and performance of the engine.

-

Hilgers, M. (2023). Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature.

↩ -

Hilgers, M. (2022). Transmissions and Drivetrain Design. Springer Vieweg.

↩ -

Berns, K., Dressler, K., Fleischmann, P., Grges, D., Kalmar, R., Sauer, B., Stephan, N., Teutsch, R., & Thul, M. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.