This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

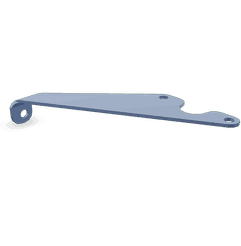

The Oil Tube Bracket 3933597, manufactured by Cummins, is a component designed to support the efficient operation of commercial truck engines. This bracket plays a role in the lubrication system by ensuring the secure attachment and proper routing of oil tubes. Cummins, a well-established name in the commercial truck industry, is known for producing reliable and high-quality engine components.

Purpose and Function

The Oil Tube Bracket 3933597 is integral to the lubrication system of a truck engine. It facilitates the secure attachment and precise routing of oil tubes, which are responsible for delivering lubricant to various engine components. By maintaining the correct positioning of these tubes, the bracket helps ensure that oil is distributed efficiently throughout the engine, contributing to optimal performance and longevity of the engine parts 1.

Key Features

The Oil Tube Bracket 3933597 is designed with several key features that enhance its functionality and durability. Constructed from high-quality materials, this bracket offers excellent corrosion resistance, making it suitable for use in harsh operating environments. Its robust design ensures it can withstand the vibrations and stresses associated with commercial truck engines. Additionally, the bracket is engineered to be compatible with various Cummins engine models, ensuring a seamless fit and function 2.

Benefits

Utilizing the Oil Tube Bracket 3933597 provides several advantages. The secure attachment and proper routing of oil tubes contribute to enhanced engine performance by ensuring consistent lubrication. This, in turn, helps maintain engine reliability and reduces the risk of wear and tear on critical components. Furthermore, the bracket’s design simplifies maintenance procedures, allowing for easier access and inspection of the oil tubes 3.

Installation

Proper installation of the Oil Tube Bracket 3933597 is vital for its effective function. The installation process involves several steps to ensure correct positioning and secure fastening. First, the engine compartment should be accessed, and the existing oil tubes should be inspected for any damage. The bracket should then be positioned according to the manufacturer’s guidelines, ensuring it aligns correctly with the oil tube pathways. Once in place, the bracket should be fastened securely using the provided hardware, taking care to avoid over-tightening, which could damage the bracket or the oil tubes.

Maintenance and Troubleshooting

Routine inspection and maintenance of the Oil Tube Bracket 3933597 are recommended to ensure its continued reliable performance. Regular checks should include verifying the tightness of the fastening hardware and inspecting the bracket for any signs of corrosion or damage. Common issues that may arise include loose connections or corrosion, which can be addressed by re-tightening the hardware or applying a corrosion-resistant coating. If significant damage is detected, replacement of the bracket may be necessary.

Safety Considerations

When working with the Oil Tube Bracket 3933597, several safety precautions should be observed. Proper handling of the bracket is important to avoid injury or damage to the component. Additionally, ensuring that the engine is turned off and cooled before beginning any maintenance or installation procedures is crucial. Following the manufacturer’s guidelines for installation and maintenance will help ensure safe and effective use of the bracket.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation for innovation, quality, and reliability in the commercial truck industry. The company’s product range includes a variety of engine types and components, all designed to meet the demanding requirements of commercial applications. Cummins’ commitment to excellence is reflected in its extensive lineup of durable and high-performing engine parts, including the Oil Tube Bracket 3933597.

Cummins Oil Tube Bracket 3933597 Compatibility

The Cummins Oil Tube Bracket part number 3933597 is designed to fit seamlessly with various engine models, ensuring proper alignment and functionality of the oil tube system. This bracket is essential for maintaining the integrity of the oil flow within the engine, preventing leaks, and ensuring optimal engine performance.

Engine Compatibility

-

6B5.9 Series

- The 3933597 Oil Tube Bracket is specifically engineered to fit the 6B5.9 engine series. This bracket ensures that the oil tube is securely fastened, allowing for efficient oil circulation and reducing the risk of oil leaks.

-

Other Cummins Engines

- While the primary focus is on the 6B5.9 series, the 3933597 Oil Tube Bracket may also be compatible with other Cummins engine models. It is crucial to verify the compatibility with the specific engine model to ensure a proper fit and function.

Installation and Functionality

-

Secure Mounting

- The bracket is designed to provide a secure mounting point for the oil tube, ensuring that it remains in place under various operating conditions. This is critical for maintaining the engine’s lubrication system integrity.

-

Prevents Leaks

- By securing the oil tube, the bracket helps prevent leaks that could lead to oil loss and potential engine damage. Proper installation of this bracket is essential for maintaining engine health.

-

Ease of Maintenance

- The design of the 3933597 Oil Tube Bracket allows for easy access during maintenance, making it simpler to inspect and service the oil tube system without extensive disassembly.

Role of Part 3933597 Oil Tube Bracket in Engine Systems

The 3933597 Oil Tube Bracket is an integral component in the assembly and maintenance of engine systems, particularly in ensuring the secure and efficient routing of oil tubes. This bracket plays a role in the following engine components:

Fuel System Integration

In fuel-injected engines, the Oil Tube Bracket aids in the precise placement and support of oil tubes that run adjacent to fuel lines. This ensures that oil tubes do not interfere with fuel lines, maintaining the integrity of the fuel delivery system. The bracket’s secure mounting points prevent oil tube displacement, which could otherwise lead to fuel system inefficiencies or even failures.

Filter Assembly Support

The Oil Tube Bracket is also essential in supporting oil filters within the engine bay. By providing a stable attachment point for oil tubes leading to and from the filter, it ensures that the filter receives a consistent oil flow. This consistent flow is vital for the filter’s effectiveness in removing contaminants from the oil, thereby prolonging engine life and maintaining optimal performance.

Enhanced Engine Lubrication

By securely holding oil tubes in place, the bracket contributes to a more reliable lubrication system. This is particularly important in high-performance engines where oil pressure and flow must be meticulously managed to prevent engine wear and damage. The bracket’s role in maintaining tube alignment and integrity helps ensure that oil reaches all lubricated components efficiently.

Facilitation of Maintenance

The Oil Tube Bracket simplifies engine maintenance by allowing for easier access to oil tubes and filters. Mechanics can quickly disconnect and reconnect oil tubes during service intervals, reducing downtime and making routine maintenance more straightforward. This accessibility is particularly beneficial during oil changes or when diagnosing oil system issues.

Conclusion

The 3933597 Oil Tube Bracket is a key component in the engine’s oil system, supporting fuel system integration, filter assembly, enhanced lubrication, and facilitating maintenance. Its role in securing oil tubes ensures the engine operates smoothly and efficiently.

-

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill, 2018.

↩ -

Hilgers, Michael and Achenbach, Wilfried. Vocational Vehicles and Applications. Springer Vieweg, 2021.

↩ -

Zhan, Quansheng, Eben, Shengbo, and Deng, Li Kun. Automotive Heating Ventilation and Air Conditioning. Jones Bartlett Learning, 2018.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.