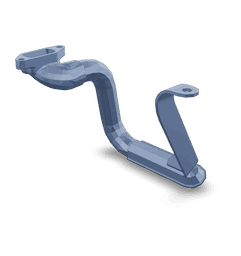

3959097

Lubricating Oil Suction Tube

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Lubricating Oil Suction Tube, identified by Part #3959097, is a component manufactured by Cummins, a renowned name in the automotive industry. This tube is integral to the lubrication system of heavy-duty trucks, ensuring the efficient circulation of oil within the engine 2.

Function and Operation

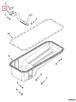

The Lubricating Oil Suction Tube operates by drawing oil from the oil pan and directing it towards the engine’s lubrication system. This process is vital for maintaining adequate oil levels and ensuring consistent oil circulation, which is necessary for the engine’s moving parts to function smoothly and efficiently 1.

Purpose of the Lubricating Oil Suction Tube

In the operation of a truck, the Lubricating Oil Suction Tube plays a specific role by facilitating the continuous flow of oil to critical engine components. This contributes to the overall performance and longevity of the engine by reducing friction and wear on moving parts 3.

Key Features

The Lubricating Oil Suction Tube is characterized by its robust material composition and design elements tailored for durability and efficiency. Its construction ensures it can withstand the high pressures and temperatures within the engine compartment, while its design optimizes oil flow 4.

Benefits

The advantages of the Lubricating Oil Suction Tube include enhanced engine lubrication, which leads to reduced wear on engine components. Additionally, its durable construction contributes to the overall longevity of the engine. Improved lubrication can also play a role in maintaining engine efficiency, potentially contributing to better fuel economy 1.

Installation and Compatibility

Proper installation of the Lubricating Oil Suction Tube is crucial for its effective operation. It is designed to meet specific requirements to ensure compatibility with various truck models. Attention to manufacturer guidelines during installation helps maintain the integrity of the lubrication system 2.

Maintenance and Troubleshooting

Routine maintenance of the Lubricating Oil Suction Tube involves checking for signs of wear or damage and ensuring there are no leaks or blockages in the oil flow path. Troubleshooting common issues, such as leaks or reduced oil flow, may involve inspecting connections and the tube itself for any signs of damage or obstruction 3.

Cummins Overview

Cummins Inc. is a leader in the automotive industry, known for its high-quality components for heavy-duty trucks. With a rich history and a strong reputation, Cummins is committed to innovation and excellence in engine technology, providing reliable and efficient solutions for the transportation sector 4.

Lubricating Oil Suction Tube (Part 3959097) Compatibility with Cummins Engines

The Cummins part 3959097, a lubricating oil suction tube, is designed to fit a variety of Cummins engines, ensuring efficient oil flow and maintaining engine performance. This part is compatible with several engine models, grouped primarily by their series and displacement.

ISB Series Engines

- ISB CM2150

- ISB CM850

- ISB/ISD6.7 CM2150 SN

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

The ISB series engines, ranging from 6.7 liters to 8.9 liters, benefit from the precise fit of the lubricating oil suction tube. This part ensures that the oil is drawn effectively from the sump, maintaining the necessary lubrication for engine components.

ISBE Series Engines

- ISBE CM800

The ISBE series, known for its high-performance and reliability, also integrates the lubricating oil suction tube seamlessly. This ensures that the engine operates smoothly, with consistent oil pressure and flow.

QSB Series Engines

- QSB5.9 CM850

- QSB6.7 CM2250

- QSB6.7 CM850 (CM2850)

- QSB6.7 M CM2250

The QSB series engines, with displacements ranging from 5.9 liters to 6.7 liters, are designed to handle demanding applications. The lubricating oil suction tube is critical in these engines, ensuring that oil is delivered to the moving parts under all operating conditions, enhancing durability and performance.

The lubricating oil suction tube (part 3959097) is engineered to fit these diverse engines, providing a reliable and efficient oil flow system that is essential for maintaining engine health and longevity.

Role of Part 3959097 Lubricating Oil Suction Tube in Engine Systems

The Lubricating Oil Suction Tube, part 3959097, is integral to the efficient operation of engine systems by facilitating the smooth and consistent flow of oil from the oil pan to the engine’s lubrication system. This component is designed to draw oil from the oil pan, where it is stored, and direct it towards the oil pump.

Once the oil is within the suction tube, it is transported to the oil pump, which pressurizes the oil before distributing it throughout the engine. This ensures that all moving parts, such as the crankshaft, camshaft, and pistons, receive the necessary lubrication to reduce friction and wear.

The consistent flow of oil is essential for maintaining the engine’s performance and longevity. The suction tube’s design allows it to effectively handle the oil, even when the engine is operating at high speeds or under varying load conditions. This reliability in oil delivery helps in stabilizing engine temperature and enhancing overall efficiency.

In summary, part 3959097 plays a significant role in the lubrication process by ensuring a steady supply of oil from the oil pan to the engine’s critical components, thereby supporting the engine’s smooth operation and durability.

Conclusion

The Lubricating Oil Suction Tube, part 3959097, is a critical component in the lubrication system of heavy-duty trucks, ensuring efficient oil circulation and engine performance. Its robust design and compatibility with various Cummins engines make it a reliable choice for maintaining engine health and longevity.

-

Automotive Lubricants Reference Book, Arthur J Caines, Roger F Haycock and John E Hillier, SAE International, 2004

↩ ↩ -

Automotive Braking Systems CDX Master Automotive Technician Series, Nicholas Goodnight and Kirk VanGelder, Jones Bartlett Learning, 2019

↩ ↩ -

Diesel Engine Combustion, Emissions and Condition Monitoring, Saiful Bari, InTech, 2013

↩ ↩ -

High Speed Off-Road Vehicles, Bruce Maclaurin, Wiley, 2018

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.