This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

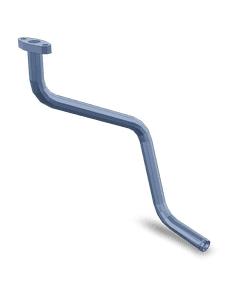

The Tur Oil Drain Tube (3967320) is a component designed by Cummins for use in heavy-duty trucks. Its purpose is to facilitate the efficient drainage of oil from the engine, which is a key aspect of regular maintenance. Cummins, a well-established manufacturer in the automotive industry, produces this part with a focus on durability and performance, ensuring that it meets the demanding requirements of heavy-duty applications 1.

Function and Operation

The Tur Oil Drain Tube operates as a conduit for oil drainage within the truck’s engine system. When it is time to change the oil, this tube allows for a controlled and efficient flow of oil out of the engine. Its design ensures that oil is directed away from the engine compartment, minimizing the risk of spills and contamination. The tube’s role is vital in maintaining the engine’s lubrication system, which is necessary for the engine’s operation and longevity 2.

Key Features

The Tur Oil Drain Tube is constructed from materials that are resistant to the high temperatures and pressures found within a truck engine. Its design includes features such as a secure fitting mechanism to ensure a tight seal with the engine’s oil pan. Additionally, the tube may have a reinforced structure to withstand the physical demands of heavy-duty use. These features contribute to the tube’s reliability and performance in facilitating efficient oil drainage 3.

Benefits of Using Tur Oil Drain Tube

Utilizing the Tur Oil Drain Tube offers several advantages. It contributes to improved engine performance by ensuring that old oil is effectively removed during maintenance, which helps in maintaining the engine’s lubrication system. The tube’s design also aids in prolonging the engine’s lifespan by facilitating regular and thorough oil changes. Furthermore, the ease of use provided by this tube can reduce maintenance time, thus enhancing overall truck efficiency.

Installation Process

Installing the Tur Oil Drain Tube requires following a series of steps to ensure a proper fit. Begin by ensuring the engine is cool and the oil has been allowed to settle. Then, locate the oil drain plug and position the tube to align with the plug’s opening. Secure the tube in place, ensuring a tight seal to prevent leaks. It is important to follow best practices, such as using the correct tools and checking for proper alignment, to ensure the tube is installed effectively.

Maintenance and Care

Regular maintenance of the Tur Oil Drain Tube is important to ensure its continued effectiveness. This includes checking for signs of wear or damage after each use and cleaning the tube to remove any oil residue. Addressing common issues, such as leaks or misalignment, promptly can help prolong the tube’s lifespan and maintain its performance.

Compatibility and Usage

The Tur Oil Drain Tube is designed for use with specific types of trucks and engines. To determine compatibility, it is necessary to consult the manufacturer’s guidelines or a professional technician. Understanding the specific requirements of your truck’s engine will ensure that the tube is suitable for your application.

Safety Considerations

When installing or maintaining the Tur Oil Drain Tube, it is important to adhere to safety practices. This includes wearing appropriate personal protective equipment, ensuring the engine is cool before beginning work, and following all manufacturer guidelines and safety protocols. Safety is paramount to prevent accidents and ensure the longevity of the component.

Cummins: Manufacturer Overview

Cummins Inc. is a leader in the design, manufacture, and distribution of diesel and natural gas engines, as well as related technologies. With a history of innovation and a commitment to quality, Cummins has established a reputation for producing reliable and high-performance components for the automotive industry. Their product range includes a variety of engine and powertrain components, designed to meet the needs of heavy-duty applications.

Tur Oil Drain Tube (Part 3967320) Compatibility with Cummins Engines

The Tur Oil Drain Tube, identified by the part number 3967320, is a crucial component designed to facilitate the drainage of lubricating oil from the turbocharger system. This part is engineered to ensure efficient and reliable oil management, which is vital for maintaining the performance and longevity of the turbocharger.

Compatibility with Specific Cummins Engines

The Tur Oil Drain Tube is compatible with several Cummins engine models, including:

- ISC CM850

- ISL9 CM2150 SN

- ISL9.5 CM2880 L138

Grouping by Engine Series

The compatibility of the Tur Oil Drain Tube can be grouped by the engine series for better understanding:

-

ISC Series: The ISC CM850 engine is part of the ISC series, which is known for its robust design and high performance. The Tur Oil Drain Tube ensures that the oil is effectively drained from the turbocharger, preventing oil accumulation that could lead to performance degradation.

-

ISL Series: The ISL9 CM2150 SN and ISL9.5 CM2880 L138 engines belong to the ISL series, which is designed for heavy-duty applications. The Tur Oil Drain Tube in these engines plays a critical role in maintaining the efficiency of the turbocharger by ensuring that the oil is properly drained and does not interfere with the turbocharger’s operation.

The Tur Oil Drain Tube is a critical component that ensures the efficient operation of the turbocharger system in these Cummins engines. Its compatibility with the ISC and ISL series highlights its importance in maintaining the performance and reliability of these engines.

Role of Part 3967320 Tur Oil Drain Tube in Engine Systems

The Part 3967320 Tur Oil Drain Tube is an essential component in the efficient operation of turbocharger systems within various engine setups. Its primary function is to facilitate the drainage of oil from the turbocharger, ensuring that excess oil does not accumulate and potentially cause performance issues.

Integration with Turbocharger Plumbing

In turbocharger systems, the oil drain tube is meticulously integrated into the turbocharger plumbing. This integration ensures that oil, which is used for lubricating the turbocharger’s moving parts, is efficiently circulated and drained. The tube connects to the oil return line, allowing used oil to flow back to the engine’s oil sump for recirculation or disposal. This process is vital for maintaining the turbocharger’s operational integrity and longevity.

Interaction with Turbocharger

The turbocharger relies on a steady supply of oil for lubrication, cooling, and, in some cases, actuation of variable geometry systems. The Tur Oil Drain Tube plays a significant role in this by ensuring that oil does not overfill the turbocharger housing. This balance is essential for preventing oil leakage and maintaining optimal turbocharger performance. The tube is designed to handle the specific oil flow rates and pressures associated with turbocharger operation, ensuring that the system remains efficient and reliable.

Overall System Efficiency

By effectively managing oil levels within the turbocharger, the Tur Oil Drain Tube contributes to the overall efficiency of the engine system. Proper oil drainage prevents issues such as oil coking, which can lead to turbocharger failure. Additionally, it helps in maintaining the correct oil temperature and viscosity, which are critical for the turbocharger’s moving parts to function smoothly.

Conclusion

In summary, the Part 3967320 Tur Oil Drain Tube is a key component in the turbocharger plumbing system, ensuring that oil is efficiently managed to support the turbocharger’s performance and durability. Its integration with turbocharger plumbing, interaction with the turbocharger, and contribution to overall system efficiency highlight its importance in maintaining the performance and reliability of heavy-duty engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.