This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

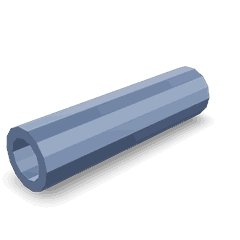

The Cummins 3968057 Wear Sleeve is a critical component in heavy-duty truck engines, designed to enhance engine efficiency and longevity. This article explores its purpose, features, benefits, installation process, maintenance, common failure modes, and compatibility with various Cummins engines.

Purpose and Function

This Cummins part is strategically placed within the engine to interface with moving parts. It provides a protective layer that minimizes friction and wear, ensuring the integrity of engine components and contributing to smooth operation and efficiency 1.

Key Features

The Wear Sleeve is engineered from materials that offer high resistance to wear and corrosion, ensuring durability under demanding conditions. Its precise design allows for optimal performance and protection of mating parts 2.

Benefits

Incorporating the 3968057 into an engine assembly leads to improved efficiency by reducing friction, potentially lowering fuel consumption. It also extends the lifespan of mating parts and the engine as a whole by reducing wear 3.

Installation Process

Proper installation of this part is essential for its effectiveness. The process includes preparing the engine compartment, aligning the sleeve, and securing it in place. Specific tools may be required, and following recommended procedures ensures optimal performance 4.

Maintenance and Troubleshooting

Regular maintenance of the Wear Sleeve is crucial for its longevity. Periodic inspections for wear or damage are recommended. Addressing signs of issues promptly can prevent more significant problems 5.

Common Failure Modes

Like any mechanical component, the Wear Sleeve is subject to failure modes such as excessive wear, cracking, or deformation. Understanding these can help in taking preventive measures. Regular inspections and maintenance can mitigate these risks 6.

Replacement Considerations

Compatibility with other engine components is key when considering replacement. Recommended replacement intervals depend on engine usage and conditions. For high-mileage engines, more frequent inspections may be advisable 7.

Cummins Overview

Cummins Inc. is renowned for its engine and power generation products, known for reliability and performance. Components like the 3968057 play a significant role in ensuring engine efficiency and durability across various sectors, including heavy-duty trucks 8.

Compatibility with Cummins Engines

The Wear Sleeve part number 3968057 is compatible with various Cummins engine models, including ISC CM2150, ISL CM2150, ISC CM554, ISL CM554, and ISL9 CM2150 SN. It ensures smooth operation and longevity by reducing wear on critical components 9.

Role in Engine Systems

This part is vital in maintaining the efficiency of engine systems, particularly in the cooler and torque converter oil systems. It acts as a protective barrier in the cooler system, ensuring smooth coolant flow and preventing leaks. In the torque converter oil system, it protects sensitive components from excessive wear, maintaining consistent oil flow and extending the lifespan of the torque converter 10.

Conclusion

The Cummins 3968057 Wear Sleeve is a crucial component for the efficient and reliable operation of heavy-duty truck engines. Its role in reducing friction, protecting engine components, and ensuring the smooth operation of critical systems underscores its importance in engine maintenance and performance.

-

Trzesniowski, M. (2023). The Complete Vehicle. Springer Nature.

↩ -

Bari, S. (2013). Diesel Engine Combustion, Emissions and Condition Monitoring. InTech.

↩ -

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

Goodnight, N., & Van Gelder, K. (2018). Automotive Braking Systems. Jones & Bartlett Learning.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for X13 CM2880 X138B. Bulletin Number 5613140.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for X13 CM2880 X138B. Bulletin Number 5613140.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for X13 CM2880 X138B. Bulletin Number 5613140.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for X13 CM2880 X138B. Bulletin Number 5613140.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for X13 CM2880 X138B. Bulletin Number 5613140.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for X13 CM2880 X138B. Bulletin Number 5613140.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.