This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

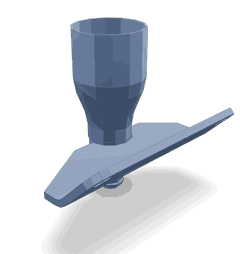

The Cummins 3971506 Oil Filler Neck Tube is a component designed for use in heavy-duty truck engines. It facilitates the addition of oil to the engine’s lubrication system, ensuring that the engine receives the necessary lubrication for optimal performance and longevity 1.

Basic Concepts of Oil Filler Neck Tubes

An Oil Filler Neck Tube is a conduit through which oil is added to the engine’s lubrication system. It provides a secure and convenient pathway for oil to reach the engine’s internal components, contributing to the overall performance and durability of the engine 2.

Purpose and Role in Truck Operation

This Cummins part serves as the entry point for oil into the engine’s lubrication system. It ensures that the engine maintains the correct oil level, which is necessary for reducing friction between moving parts, cooling the engine, and cleaning internal components 3.

Key Features

The 3971506 is constructed from durable materials that are resistant to the high temperatures and pressures found within an engine environment. Its design includes features such as a secure fitting mechanism to prevent oil leaks and a cap that can be easily removed for oil addition 4.

Benefits

Using this part offers several benefits. It contributes to improved engine performance by ensuring consistent oil levels, which are vital for engine health. The design of the tube allows for ease of use during oil changes, reducing the time and effort required for maintenance.

Installation Process

Installing the Oil Filler Neck Tube requires careful attention to ensure a secure and effective fit. Preparatory steps include cleaning the installation area and ensuring that all old gaskets or seals are removed. The necessary tools for installation may include a torque wrench for tightening the tube to the specified torque. Following the manufacturer’s guidelines for installation is recommended to ensure proper fitment and function.

Maintenance Tips

To maintain the 3971506, regular inspection for signs of wear or damage is advised. Cleaning the area around the tube can prevent debris from entering the engine during oil changes. If any leaks or damage are detected, considering replacement of the tube is recommended to maintain the integrity of the engine’s lubrication system.

Troubleshooting Common Issues

Common problems with the Oil Filler Neck Tube may include leaks or blockages. Troubleshooting steps can involve checking for proper installation, ensuring that all seals are intact, and cleaning the tube and surrounding area to remove any obstructions. Addressing these issues promptly can help maintain the efficiency of the engine’s lubrication system.

Compatibility

This part is designed to fit seamlessly with several engine models, including QSB5.9 and CM550 engines. This compatibility ensures that the oil filling process is efficient and secure, contributing to the overall maintenance and longevity of the engine.

Role in Engine Systems

The 3971506 plays a role in the engine’s lubrication system by serving as the primary conduit for introducing oil into the engine. It interfaces directly with the oil fill port, ensuring a seamless connection for oil replenishment.

Conclusion

The Cummins 3971506 Oil Filler Neck Tube is a vital component in the maintenance and operation of heavy-duty truck engines. Its design and features contribute to the engine’s performance and durability by ensuring proper lubrication. Regular maintenance and prompt troubleshooting of common issues are essential for the longevity of the engine’s lubrication system.

-

Hilgers, Michael. Entire Vehicle: Second Edition. Springer Nature, 2023.

↩ -

Bell, Joseph A. Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning, 2014.

↩ -

Reif, Konrad Ed. Gasoline Engine Management Systems and Components. Springer Vieweg, 2015.

↩ -

Wharton, A. J. Diesel Engines. Butterworth-Heinemann Ltd, 1991.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.