This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

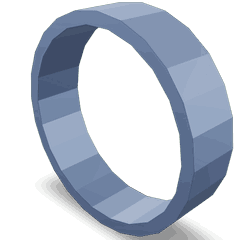

The Cummins 4003402 Wear Sleeve is a component designed to enhance the operation of commercial trucks. Its purpose is to provide a durable and reliable solution for wear and friction within the engine or transmission system. The significance of this part lies in its ability to contribute to the overall efficiency and longevity of the truck’s engine or transmission 1.

Purpose and Function

The 4003402 Wear Sleeve plays a role in the operation of a truck by reducing friction and wear on moving parts within the engine or transmission system. It is typically placed in areas where components experience high levels of friction and stress. By doing so, it helps maintain the functionality and durability of the truck, ensuring smooth operation and reducing the likelihood of premature wear or failure 2.

Key Features

The Cummins 4003402 Wear Sleeve is characterized by its material composition, which is designed to withstand high levels of friction and stress. It is crafted from durable materials that offer resistance to wear and corrosion. The design of the wear sleeve includes features that enhance its performance, such as precise dimensions to ensure a proper fit and optimal function within the engine or transmission system 3.

Benefits

Using the 4003402 Wear Sleeve can lead to improved engine or transmission performance. It contributes to increased durability by reducing wear on critical components. Additionally, the wear sleeve can offer potential cost savings over time by extending the lifespan of the engine or transmission and reducing the frequency of repairs or replacements.

Installation Process

Proper installation of the 4003402 Wear Sleeve involves several steps to ensure optimal performance and longevity. It is recommended to use the appropriate tools and equipment for a secure and precise fit. Following manufacturer guidelines and procedures during installation is crucial to achieve the best results and ensure the wear sleeve functions as intended within the engine or transmission system.

Troubleshooting and Maintenance

To troubleshoot common issues related to the 4003402 Wear Sleeve, it is important to conduct regular inspections and maintenance. This includes checking for signs of wear, damage, or improper fit. Recommended maintenance practices may involve cleaning the wear sleeve and surrounding components, as well as lubricating moving parts to reduce friction and enhance performance. Adhering to these practices can help prolong the lifespan of the wear sleeve and ensure continued reliable operation.

Compatibility and Application

The 4003402 Wear Sleeve is compatible with various truck models and engine types, making it a versatile component for different applications. It is suitable for use in a range of operating environments and conditions, providing reliable performance and durability across diverse settings.

Performance Metrics

Performance metrics associated with the 4003402 Wear Sleeve include expected lifespan, efficiency gains, and adherence to industry standards or certifications. These metrics provide valuable insights into the wear sleeve’s effectiveness in enhancing engine or transmission performance and durability.

Customer Reviews and Feedback

Customer reviews and feedback on the 4003402 Wear Sleeve offer real-world experiences and insights from users in the field. These testimonials can provide valuable information on the wear sleeve’s performance, durability, and overall satisfaction among commercial truck operators.

Cummins Overview

Cummins Inc. is a renowned manufacturer in the commercial truck industry, known for its history of innovation, quality products, and strong reputation. The company offers a wide range of engine and component solutions designed to meet the demanding needs of commercial truck operators, ensuring reliable performance and durability in various operating conditions.

Cummins Wear Sleeve 4003402 Compatibility

The Cummins Wear Sleeve part number 4003402 is designed to fit a variety of engine models, providing essential wear protection and longevity to critical components. Below is a detailed overview of its compatibility with specific engine types.

K19 Series Engines

The Wear Sleeve 4003402 is compatible with the following K19 series engines:

- QSK19 CM850 MCRS

- QSK50 CM2150 K107

- QSK50 CM2150 MCRS

- QSK60 CM850 MCRS

- QSK95 CM2350 K111

- QSK95 CM2350 K113

Application Insights

- QSK19 CM850 MCRS and QSK60 CM850 MCRS: These engines benefit from the Wear Sleeve in maintaining optimal performance and reducing wear in high-stress areas.

- QSK50 CM2150 Models: The Wear Sleeve 4003402 is crucial for the longevity of the K107 and MCRS variants, ensuring smooth operation and minimizing maintenance needs.

- QSK95 CM2350 Models: For the K111 and K113 variants, this wear sleeve plays a significant role in protecting the engine from excessive wear, thereby extending the engine’s operational life.

By ensuring that the Wear Sleeve 4003402 is correctly installed, operators can expect enhanced durability and reliability of their engines.

Role of Part 4003402 Wear Sleeve in Engine Systems

The 4003402 Wear Sleeve is an integral component in various engine systems, contributing to their efficient operation and longevity.

In the cooler system, the Wear Sleeve ensures smooth operation by reducing friction between moving parts, thereby enhancing the cooler’s efficiency in maintaining optimal engine temperatures.

Within the engine oil system, it plays a significant role in protecting the oil passages from wear and tear, ensuring consistent oil flow and pressure, which is essential for engine lubrication and cooling.

In the cooling system gasket kit, the Wear Sleeve is used to seal and protect the connections between different components, preventing leaks and ensuring the system’s integrity.

The housing components, including the thermostat and plumbing, benefit from the Wear Sleeve by maintaining a tight fit and reducing the risk of wear-induced failures.

In the thermostat housing, the Wear Sleeve helps in maintaining the precise temperature control necessary for efficient engine operation.

For the pump systems, such as the water pump and the water top-level assembly pump, the Wear Sleeve is vital in ensuring that the pump components operate smoothly, reducing the likelihood of premature wear and enhancing the pump’s efficiency in circulating water through the engine.

Overall, the 4003402 Wear Sleeve is a key component in enhancing the durability and performance of various engine systems by providing necessary protection against wear and ensuring smooth operation of moving parts.

Conclusion

The Cummins 4003402 Wear Sleeve is a critical component for enhancing the durability and performance of commercial truck engines. Its role in reducing friction and wear on moving parts contributes to the overall efficiency and longevity of the engine or transmission system. Proper installation, regular maintenance, and adherence to manufacturer guidelines are essential for maximizing the benefits of this Cummins part. With its compatibility across various engine models and positive customer feedback, the 4003402 Wear Sleeve stands as a reliable solution for wear protection in demanding operating conditions.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.