4058969

Oil Piston Ring

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

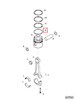

The Cummins Oil Piston Ring (Part #4058969) is designed to enhance the performance and efficiency of heavy-duty truck engines. It plays a significant role in maintaining optimal engine operation by controlling oil consumption and ensuring proper compression.

Basic Concepts of Oil Piston Rings

Oil piston rings are components in internal combustion engines that manage lubrication between the piston and the cylinder wall. They regulate the amount of oil that reaches the combustion chamber, contributing to engine efficiency and performance by reducing friction and wear on engine components 1.

Purpose and Role of the Cummins Oil Piston Ring

This Cummins part is engineered to control oil consumption within the engine. It maintains the correct oil film thickness on the cylinder walls, which is vital for reducing friction and wear. Additionally, it maintains compression by preventing excessive oil from entering the combustion chamber, which can lead to inefficient fuel burning and increased emissions 2.

Key Features of the Cummins Oil Piston Ring

The Oil Piston Ring is characterized by its precise design and material selection. It is made from high-quality materials that offer resistance to wear and corrosion. The ring features a specific profile and tension that allow it to effectively scrape excess oil from the cylinder walls while maintaining a seal to keep oil from entering the combustion chamber.

Benefits of Using Cummins Oil Piston Rings

Utilizing Cummins Oil Piston Rings can lead to improved engine efficiency due to better lubrication and reduced friction. They contribute to lower oil consumption, resulting in cost savings and less frequent oil changes. Furthermore, these rings can enhance the longevity of engine components by providing consistent and reliable performance 3.

Installation and Compatibility

When installing the Cummins Oil Piston Ring, it is important to follow manufacturer guidelines to ensure optimal performance. Proper installation involves careful handling to avoid damage to the ring and ensuring it is seated correctly within the piston groove. Specific requirements may include using the correct tools and lubricants to facilitate a smooth installation process.

Troubleshooting Common Issues

Common issues associated with oil piston rings may include excessive oil consumption or engine knocking. These problems can often be traced back to improper installation, wear, or damage to the rings. Troubleshooting steps may involve inspecting the rings for signs of wear, ensuring they are properly seated, and checking for any damage that may affect their performance.

Maintenance Tips

To ensure the long-term performance of the Cummins Oil Piston Ring, regular maintenance is recommended. This includes periodic inspections to check for wear or damage, and adhering to the manufacturer’s recommended service intervals for oil changes and engine inspections. Best practices for engine care, such as using the correct grade of oil and keeping the engine clean, can also contribute to the longevity of the piston rings.

Compatibility of Oil Piston Ring Part 4058969 with Cummins Engines

The Oil Piston Ring part 4058969, manufactured by Cummins, is designed to fit a variety of Cummins engines. Here is a breakdown of its compatibility with the listed engine models:

G855 Series

- G855

- G855 CM558

- GTA855 CM558 (CM2358)

N14 Series

- N14 CELECT PLUS

- N14 G

- N14 MECHANICAL

NH/NT 855 Series

- NH/NT 855

QSN14 Series

- QSN14 CM876 N103

- QSNT14 CM876 N102

V Series

- V28

- V903

- VTA903 CM2250 V105

Role of Part 4058969 Oil Piston Ring in Engine Systems

This part is an integral component in maintaining the efficiency and performance of various engine systems. Its primary function is to control oil consumption and ensure proper lubrication between the piston and the cylinder wall. This is essential for reducing friction and wear, which in turn enhances the longevity and reliability of the engine.

Interaction with Key Engine Components

Cylinder Block and Cylinder Head

The Oil Piston Ring works in conjunction with the cylinder block and cylinder head to create a sealed environment. This seal is vital for maintaining compression within the combustion chamber, ensuring that the air-fuel mixture is efficiently burned. The ring’s ability to control oil flow prevents excessive oil from entering the combustion chamber, which could lead to fouling of spark plugs and decreased engine performance.

Piston and Connecting Rod

Installed on the piston, the Oil Piston Ring interacts directly with the piston and connecting rod assembly. By managing oil lubrication, it reduces friction between the piston skirt and the cylinder wall. This not only improves engine efficiency but also reduces heat generation, which can be detrimental to the connecting rod and other moving parts.

Camshaft and Crankshaft

Although the Oil Piston Ring does not directly interface with the camshaft or crankshaft, its role in maintaining optimal engine lubrication indirectly supports these components. Proper lubrication ensures that the camshaft lobes and crankshaft journals operate smoothly, reducing the risk of wear and enhancing the overall performance and durability of the engine.

Contribution to Performance and Overhaul Kits

In performance kits and overhaul kits, the inclusion of high-quality Oil Piston Rings like part 4058969 is standard. These rings are designed to withstand higher operating pressures and temperatures, which are common in performance-tuned engines. They contribute to improved engine response, increased power output, and better fuel efficiency.

Role in Spare Parts and Onboard Spares

For engines equipped with onboard spares or those that require frequent maintenance, the Oil Piston Ring is a key component in spare parts kits. Its reliability and ease of replacement make it a staple in ensuring that engines can be quickly returned to operational status with minimal downtime.

Integration with Turbocharger and Plumbing

In turbocharged engines, the Oil Piston Ring plays an additional role in managing the increased stresses and temperatures generated by forced induction. Proper lubrication is essential to handle the additional load, ensuring that the turbocharger and its plumbing components operate within safe parameters.

Conclusion

The part 4058969 Oil Piston Ring is a fundamental component in the intricate network of an engine system. Its role in controlling oil consumption, ensuring proper lubrication, and maintaining seals within the combustion chamber directly contributes to the engine’s performance, durability, and overall efficiency.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.