This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

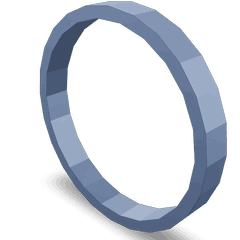

The 4324107 Wear Sleeve, a component manufactured by Cummins, is specifically designed for use in commercial trucks. This part plays a role in the mechanical system of trucks by providing necessary support and protection to other components. Cummins Inc. is renowned for its quality and innovation in the automotive industry 1.

Basic Concepts of Wear Sleeves

Wear sleeves are components used in various types of machinery to protect and support other parts that undergo significant wear and tear. They contribute to the longevity and efficiency of mechanical components by reducing friction and wear, thereby enhancing the overall performance and lifespan of the machinery 2.

Purpose of the 4324107 Wear Sleeve

This Cummins part is positioned within the truck’s mechanical system to support and protect specific components from wear. Its placement and function are integral to maintaining the efficiency and reliability of the truck’s operation. By providing a barrier against wear, it helps in maintaining the optimal performance of the associated components.

Key Features

The 4324107 is characterized by its robust material composition and design elements that enhance its performance and durability. It is crafted from materials that offer high resistance to wear and corrosion, ensuring it can withstand the demanding conditions within a commercial truck’s engine. Its design includes features that facilitate easy installation and integration with other components.

Benefits of Using the 4324107 Wear Sleeve

Incorporating this part into a truck’s mechanical system offers several advantages. These include improved engine performance due to reduced friction, lower maintenance costs as a result of extended component lifespan, and enhanced reliability of the truck’s operation. The wear sleeve contributes to the overall efficiency and durability of the truck’s engine.

Installation Process

Installing the 4324107 requires following a specific procedure to ensure proper integration with the truck’s mechanical system. The process involves preparing the area for installation, using the appropriate tools to fit the wear sleeve, and verifying that it is securely in place. Detailed instructions and any necessary tools should be referenced for a successful installation.

Maintenance and Care

Regular maintenance and care of the 4324107 are important for ensuring its optimal performance and longevity. This includes periodic inspections for signs of wear or damage, cleaning the area around the wear sleeve to prevent debris accumulation, and following manufacturer recommendations for any necessary replacements or repairs.

Troubleshooting Common Issues

Common issues associated with wear sleeves may include signs of wear, improper fit, or damage. Troubleshooting these problems involves identifying the specific issue, assessing the condition of the wear sleeve and surrounding components, and taking appropriate action to address the problem. This may include replacement of the wear sleeve or adjustment of other components.

Cummins: Manufacturer Overview

Cummins Inc. is a leading manufacturer in the automotive industry, with a history of innovation and commitment to quality. The company is recognized for its expertise in manufacturing components that enhance the performance and reliability of commercial vehicles. Cummins’ reputation is built on its dedication to producing high-quality, durable parts that meet the demanding requirements of the industry 3.

Role of Part 4324107 Wear Sleeve in Engine Systems

The 4324107 is an integral component in maintaining the efficiency and longevity of various engine systems. Its application spans across multiple components, each playing a significant role in the overall performance of the engine.

Filter Systems

In filter systems, the Wear Sleeve ensures a secure and smooth connection between the filter housing and the engine block. This connection is vital for the proper filtration of contaminants from the lubricating oil, thereby preserving the engine’s internal components from wear and tear.

Lubricating Oil Systems

Within lubricating oil systems, the Wear Sleeve facilitates the consistent flow of oil to critical engine parts. It acts as a buffer, reducing friction between moving parts and enhancing the lubrication process. This is particularly important in high-stress areas where oil flow must be maintained under varying engine loads.

Gasket Kits

When incorporated into gasket kits, the Wear Sleeve provides an additional layer of protection against leaks. It ensures that the gaskets seal effectively, preventing oil loss and maintaining the engine’s operational integrity.

Lubricating Oil Filter Kits

In lubricating oil filter kits, the Wear Sleeve plays a role in the efficient replacement and installation of filters. It ensures that the filter is properly aligned and sealed, which is essential for the effective removal of impurities from the oil.

Oil Cooler Repair Kits

For oil cooler repair kits, the Wear Sleeve is used to maintain the structural integrity of the oil cooler connections. It helps in dissipating heat effectively, which is crucial for maintaining optimal oil temperature and engine performance.

Service Kits

In comprehensive service kits, the Wear Sleeve is often included to address potential wear issues in various engine components. Its use in service kits underscores its importance in routine maintenance and overhaul procedures.

Tube Kits

Finally, in tube kits, the Wear Sleeve is employed to protect and reinforce tubing connections. This is particularly important in high-pressure systems where tubing integrity is paramount to safe and efficient engine operation.

Conclusion

Overall, the 4324107 is a versatile component that enhances the functionality and reliability of various engine systems. Its application in different components demonstrates its significance in maintaining engine health and performance.

-

Automotive Braking Systems CDX Master Automotive Technician Series, Nicholas Goodnight and Kirk VanGelder, Jones Bartlett Learning, 2019.

↩ -

Crolla Encyclopedia, David Crolla, Wiley, 2015.

↩ -

Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles, Andrew Brown Jr, National Academy of Sciences, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.