This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

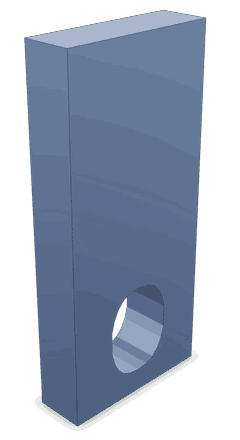

The Oil Suction Connection Spacer (Part #4333883) from Cummins is a component designed to enhance the efficiency of commercial truck engines. This spacer is integral to the lubrication system, ensuring proper oil suction from the oil pan to the engine, which is essential for maintaining engine performance and longevity 1.

Basic Concepts

The Oil Suction Connection Spacer operates within the lubrication system of a truck engine by creating a seal between the oil pan and the suction connection. This allows for the smooth and consistent flow of oil, ensuring that the engine receives a steady supply of lubricant. This lubrication is necessary for reducing friction and wear on moving parts 2.

Purpose and Function

This Cummins part facilitates the suction of oil from the oil pan to the engine, ensuring that the oil pump can draw oil efficiently. It provides a secure connection and seal, helping to prevent oil leaks and ensuring that the engine operates within optimal lubrication parameters.

Key Features

The Oil Suction Connection Spacer is typically made from durable materials to withstand the harsh conditions within an engine environment. Its design ensures a tight seal and efficient oil flow. Unique attributes such as anti-corrosion coatings or enhanced sealing mechanisms contribute to its performance and longevity.

Benefits

The advantages of the Oil Suction Connection Spacer include improved engine lubrication, which leads to reduced friction and wear on engine components. This can enhance the durability of the engine and potentially contribute to overall engine efficiency. Additionally, by ensuring a consistent oil supply, the spacer helps maintain engine performance and reliability over time.

Installation and Maintenance

Proper installation of the Oil Suction Connection Spacer involves ensuring it is correctly positioned between the oil pan and the suction connection. It is important to follow manufacturer guidelines to achieve a secure fit and seal. Recommended maintenance practices include regular inspection for signs of wear or damage, and replacement if necessary, to ensure optimal performance and longevity of the component.

Troubleshooting

Common issues with the Oil Suction Connection Spacer include oil leaks or inefficient oil suction. These problems can often be addressed by inspecting the spacer for damage or wear, ensuring it is properly installed, and replacing it if necessary. Regular maintenance and timely replacement can help prevent these issues and ensure the continued efficient operation of the engine’s lubrication system.

Manufacturer - Cummins

Cummins Inc. is renowned in the automotive industry for its high-quality engine components. With a strong reputation for reliability and performance, Cummins has a history of innovation and commitment to producing components that meet the demanding requirements of commercial truck engines. The company’s dedication to quality and customer satisfaction is reflected in its wide range of engine parts, including the Oil Suction Connection Spacer.

Application in K19 Engines

In the K19 engine series, the Oil Suction Connection Spacer (Part #4333883) plays a pivotal role in maintaining the integrity of the oil delivery system. The K19 engines, known for their robust design and reliability, benefit from this spacer by ensuring that the oil suction connection is precisely positioned. This precision is crucial for the engine’s performance and longevity, as it helps in maintaining consistent oil pressure and flow, which are essential for the engine’s smooth operation.

Grouping with Other Cummins Engines

The Oil Suction Connection Spacer (Part #4333883) is also compatible with other Cummins engine models that share similar design parameters and lubrication system requirements. These engines often include various configurations and power outputs, but they all rely on the same fundamental principles of oil delivery and pressure management. By using the same spacer part, Cummins ensures that these engines can maintain optimal performance and reliability.

Role of Part 4333883 Oil Suction Connection Spacer in Engine Systems

The Oil Suction Connection Spacer (Part #4333883) is an essential component in the lubrication system of various engine setups. It functions as an intermediary piece that ensures proper alignment and secure connection between the lubricating oil suction mounting and the lubricating oil tube.

When integrated into the system, the spacer allows for the efficient transfer of oil from the oil pan to other parts of the engine that require lubrication. It is positioned between the oil pan and the oil pan adapter kit, providing a stable and leak-proof connection. This setup is vital for maintaining the integrity of the oil suction process, ensuring that oil is consistently and reliably drawn from the oil pan.

Furthermore, the spacer plays a role in accommodating any discrepancies in dimensions between the oil pan and the oil tube suction mounting. This adaptability helps in reducing the risk of oil leaks, which could otherwise lead to inefficient lubrication and potential engine damage.

Conclusion

In summary, the Oil Suction Connection Spacer (Part #4333883) is a key element in the lubrication pathway, facilitating a seamless and secure connection that supports the overall efficiency and reliability of the engine’s oil circulation system. Its role in ensuring proper oil suction and preventing leaks is crucial for the maintenance of engine performance and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.