This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4349734 Wear Sleeve is a component designed for use in heavy-duty truck engines. Its primary role is to provide a protective layer within the engine, ensuring smooth operation and longevity of the engine components it interfaces with. This part is integral to maintaining the efficiency and reliability of the engine, particularly under demanding operational conditions.

Purpose and Function

This Cummins part is positioned within the engine assembly where it interfaces with moving parts, such as pistons or connecting rods. It plays a role in reducing friction and wear between these components, which contributes to the overall functionality and efficiency of the engine. By providing a durable surface that can withstand high stress and temperatures, the wear sleeve helps in maintaining the precision fit and movement of engine parts, which is vital for optimal engine performance 1.

Key Features

The 4349734 is characterized by its robust material composition, typically made from high-grade alloys that offer superior resistance to wear and corrosion. Its design includes precise tolerances to ensure a snug fit within the engine assembly, which is crucial for minimizing friction and maximizing efficiency. Additionally, the wear sleeve may feature unique surface treatments or coatings that further enhance its durability and performance under extreme conditions.

Benefits

Incorporating the 4349734 into an engine assembly can lead to several advantages. These include improved engine longevity due to reduced wear on critical components, lower maintenance requirements as a result of its durable construction, and enhanced operational reliability under various driving conditions. The wear sleeve’s ability to maintain a precise fit and reduce friction also contributes to more efficient engine operation, potentially leading to better fuel economy and reduced emissions 2.

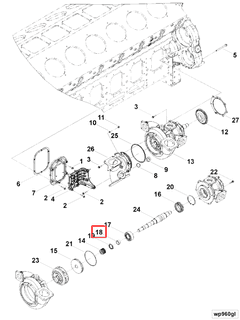

Installation and Compatibility

Proper installation of the 4349734 is crucial for ensuring its effectiveness and the overall health of the engine. Installation guidelines typically include cleaning the mating surfaces, inspecting for any damage or debris, and ensuring the wear sleeve is correctly aligned and seated. Compatibility with specific engine models is determined by the design and dimensions of the wear sleeve, ensuring it fits precisely within the engine assembly for optimal performance.

Maintenance and Troubleshooting

To ensure the 4349734 continues to perform at its best, regular maintenance is recommended. This includes periodic inspections for signs of wear or damage, cleaning to remove any contaminants that could accelerate wear, and applying the appropriate lubrication as specified by the manufacturer. Troubleshooting common issues, such as unusual noise or increased friction, may involve inspecting the wear sleeve for signs of wear, ensuring it is properly installed, and addressing any underlying issues that could affect its performance.

Common Failure Modes

The 4349734, like any engine component, can experience failure modes such as wear, corrosion, or deformation. These issues can arise from prolonged use, exposure to contaminants, or operational stresses beyond the component’s design limits. Understanding the causes behind these failure modes is important for preventing them and maintaining engine performance. Regular inspections and maintenance can help identify early signs of failure, allowing for timely intervention.

Replacement Procedures

Replacing a worn or damaged 4349734 involves several steps to ensure the engine continues to operate efficiently. The process includes safely accessing the wear sleeve within the engine assembly, removing the old component, inspecting the mating surfaces for any damage, and installing the new wear sleeve with attention to proper alignment and seating. Following manufacturer guidelines for tools, safety precautions, and installation procedures is important to ensure the replacement is successful and the engine’s performance is not compromised.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history of innovation and a commitment to quality, Cummins has established a strong reputation within the automotive industry. The company’s focus on customer satisfaction, combined with its extensive product offerings, makes it a preferred choice for heavy-duty applications, including the 4349734 Wear Sleeve.

Conclusion

The Cummins 4349734 Wear Sleeve plays a significant role in enhancing the durability, efficiency, and reliability of heavy-duty truck engines. Through its design, material composition, and precise fit within the engine assembly, this part contributes to reduced friction, wear, and maintenance requirements. Proper installation, regular maintenance, and understanding of common failure modes are essential for maximizing the performance and longevity of the engine. Cummins’ commitment to quality and innovation ensures that the 4349734 Wear Sleeve remains a vital component in the automotive industry.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.