This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

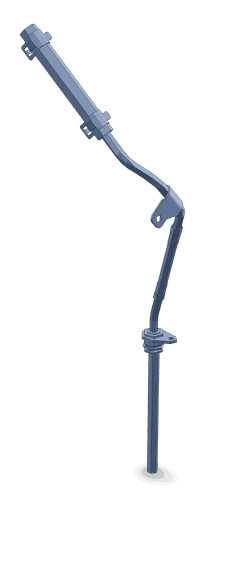

The Lubricating Oil Drain Tube, part number 4378171, is a component designed for use in heavy-duty trucks, specifically engineered to facilitate the efficient drainage of lubricating oil from the engine. This Cummins part is integral to the maintenance and operation of heavy-duty vehicles, ensuring that oil changes are conducted smoothly and effectively. Cummins Inc., a renowned manufacturer in the automotive industry, produces this drain tube. Known for its commitment to innovation and quality, Cummins provides a range of products designed to enhance the performance and reliability of vehicles 1.

Function and Operation

The Lubricating Oil Drain Tube functions within the engine system by providing a conduit for the safe and efficient drainage of used lubricating oil. During an oil change, the tube allows for the controlled release of oil from the engine, minimizing the risk of spills and ensuring that the process is both quick and clean. Its design facilitates easy access for maintenance personnel, streamlining the oil change procedure and contributing to the overall efficiency of engine maintenance routines 2.

Key Features

The Lubricating Oil Drain Tube boasts several key features that enhance its performance and durability. Constructed from high-quality materials, the tube is designed to withstand the rigors of heavy-duty use. Its precise engineering ensures a secure fit within the engine system, while its smooth interior surface facilitates the unimpeded flow of oil during drainage. Additionally, the tube’s design incorporates features that prevent leaks and ensure a tight seal, further contributing to its reliability and ease of use 3.

Benefits of Using the Lubricating Oil Drain Tube

Utilizing the Lubricating Oil Drain Tube offers several advantages. By ensuring efficient oil drainage, the tube contributes to improved engine longevity, as regular and thorough oil changes are vital for maintaining engine health. Its design also enhances the ease of maintenance, allowing for quicker and cleaner oil changes. Furthermore, the tube’s reliability in harsh operating conditions makes it a valuable component for heavy-duty trucks, where durability and performance are paramount.

Installation and Compatibility

Proper installation of the Lubricating Oil Drain Tube is crucial for its effective operation. Guidelines for installation should be followed to ensure a secure and leak-free fit within the engine system. The tube is compatible with various Cummins engine models, and its design allows for integration with other relevant truck makes and models, making it a versatile component for fleet maintenance.

Maintenance and Care

Regular maintenance and inspection of the Lubricating Oil Drain Tube are recommended to ensure optimal performance. Maintenance personnel should check for signs of wear and tear, such as cracks or deformations, and address any issues promptly to prevent leaks or blockages. Following the manufacturer’s guidelines for maintenance and care will help extend the tube’s lifespan and ensure reliable operation.

Troubleshooting Common Issues

Common problems associated with the Lubricating Oil Drain Tube may include leaks or blockages. These issues can often be resolved through routine maintenance and inspection. In the case of leaks, ensuring a tight seal and checking for damage to the tube or its connections may resolve the issue. Blockages can be addressed by cleaning the tube and ensuring that debris does not obstruct the oil flow.

Safety Considerations

When handling and working with the Lubricating Oil Drain Tube, it is important to observe safety guidelines. This includes taking precautions during installation, maintenance, and oil change procedures to avoid injury and ensure the safe and effective use of the component. Following manufacturer recommendations and safety protocols will help maintain a safe working environment.

Environmental Impact

The use and disposal of the Lubricating Oil Drain Tube should be considered in the context of environmental impact. Recycling options for the tube and proper waste management practices are important for minimizing its environmental footprint. Cummins and other manufacturers encourage the responsible disposal of automotive components to protect the environment.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins serves customers in approximately 190 countries and territories through a network of more than 600 company-owned and independent distributor facilities and more than 7,200 dealer locations. The company’s product range includes engines for on-highway, off-highway, and power generation applications, demonstrating its versatility and expertise in the automotive industry.

Compatibility

The Lubricating Oil Drain Tube part number 4378171 is designed to fit seamlessly within various engine configurations, ensuring efficient oil drainage and maintenance. This part is engineered to meet the specific requirements of different engine models, facilitating optimal engine performance and longevity.

ISV (Nissan) Engines

For ISV (Nissan) engines, the 4378171 oil drain tube is meticulously crafted to integrate with the engine’s design. It ensures that oil is effectively drained from the engine’s sump, preventing sludge buildup and maintaining the engine’s lubrication system integrity. The compatibility of this part with ISV engines underscores Cummins’ commitment to providing high-quality components that enhance engine reliability and efficiency.

Role of Part 4378171 Lubricating Oil Drain Tube in Engine Systems

The lubricating oil drain tube, identified by part number 4378171, is an integral component in the maintenance and operation of engine systems. It facilitates the efficient drainage of used lubricating oil from the crankcase, ensuring that the engine operates within optimal parameters.

Integration with the Crankcase

In engine systems, the crankcase serves as a reservoir for lubricating oil, which is essential for reducing friction between moving parts. The lubricating oil drain tube is strategically positioned to connect with the crankcase, allowing for the seamless removal of oil during maintenance procedures. This connection ensures that oil can be drained quickly and completely, minimizing the risk of contamination and facilitating the replacement with fresh lubricant.

Interaction with the Crankcase Breather

The crankcase breather system plays a significant role in maintaining the integrity of the crankcase by allowing pressure to equalize and preventing the buildup of harmful gases. The lubricating oil drain tube works in conjunction with the crankcase breather to ensure that the crankcase environment remains clean and free from excess pressure. By efficiently draining used oil, the tube helps to reduce the likelihood of oil vapors entering the breather system, which could otherwise lead to decreased efficiency and potential damage to the engine.

Overall System Arrangement

In the overall arrangement of engine components, the lubricating oil drain tube is designed to integrate seamlessly with both the crankcase and the crankcase breather system. This integration ensures that the engine can maintain optimal performance by facilitating regular oil changes and preventing the accumulation of contaminants. The tube’s placement and design are engineered to support the efficient operation of these interconnected systems, contributing to the longevity and reliability of the engine.

Conclusion

The Lubricating Oil Drain Tube, part number 4378171, plays a crucial role in the maintenance and operation of heavy-duty truck engines. Its design and features ensure efficient oil drainage, contributing to engine longevity and reliability. Proper installation, maintenance, and adherence to safety guidelines are essential for maximizing the benefits of this Cummins part. Additionally, considering the environmental impact of its use and disposal is important for responsible automotive component management.

-

Sobey, Ed. A Field Guide to Automotive Technology. Chicago Review Press, 2009.

↩ -

Majewski, Addy, and Hannu Jaskelainen. Diesel Emissions and Their Control: Second Edition. SAE International, 2023.

↩ -

Parikyan, Tigran Ed. Advances in Engine and Powertrain Research and Technology. Springer Nature, 2022.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.