The Tur Oil Drain Tube, identified by part number 4900733 and manufactured by Cummins, is a component integral to the maintenance regimen of heavy-duty trucks. This tube facilitates the efficient drainage of oil from the engine, playing a role in the overall operation and maintenance of the vehicle. Cummins, a renowned name in the automotive and heavy-duty truck industry, ensures that this component meets high standards of quality and performance 1.

Function and Operation

The Tur Oil Drain Tube operates as a conduit within the truck’s engine system, specifically designed for the drainage of oil. During the oil change process, the tube allows for the swift and clean removal of used oil from the engine, ensuring that the drainage process is both efficient and thorough. This function is vital for maintaining the engine’s health, as regular oil changes are necessary to remove contaminants and ensure the lubrication system operates effectively 2.

Key Features

The Tur Oil Drain Tube is characterized by several key features that enhance its performance and durability. Its design is tailored to fit seamlessly within the engine system, ensuring a secure and leak-free connection. The materials used in its construction are selected for their strength and resistance to the high temperatures and pressures encountered within the engine environment. Additionally, the tube may feature unique attributes such as a reinforced structure to withstand the rigors of heavy-duty use or a specialized coating to resist corrosion 3.

Benefits of Using the Tur Oil Drain Tube

Incorporating the Tur Oil Drain Tube into a truck’s maintenance routine offers several advantages. It contributes to improved engine performance by ensuring that oil changes are conducted efficiently, thereby maintaining the engine’s lubrication system in optimal condition. The design of the tube also simplifies the maintenance process, making oil changes quicker and easier for technicians. Over time, the use of this tube can lead to potential cost savings by extending the engine’s lifespan and reducing the frequency of repairs related to oil system failures 4.

Installation and Compatibility

Proper installation of the Tur Oil Drain Tube is crucial for its effective operation. The process may require specific tools and adherence to manufacturer guidelines to ensure a secure fit and prevent leaks. Compatibility with various truck models and engine types is a significant consideration, as the tube must be designed to fit within the specific configuration of the engine it services. Detailed instructions and compatibility information are typically provided by the manufacturer to guide technicians in the selection and installation process 5.

Maintenance and Troubleshooting

Regular maintenance of the Tur Oil Drain Tube is recommended to ensure its longevity and optimal performance. This may include periodic inspections for signs of wear or damage, cleaning, and, if necessary, replacement of the tube. Common issues that may arise with the tube include leaks or blockages, which can often be addressed through routine maintenance checks and timely repairs. Troubleshooting tips and solutions are available to assist technicians in resolving any problems that may occur 6.

Safety Considerations

When working with the Tur Oil Drain Tube, it is important to observe safety guidelines and precautions. Handling hot oil requires careful attention to avoid burns, and ensuring the tube is properly sealed is crucial to prevent leaks that could pose a fire hazard or environmental risk. Technicians should follow safety protocols and use appropriate personal protective equipment when performing maintenance or repairs on the oil drainage system 7.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive and heavy-duty truck industry. The company’s commitment to excellence is evident in its wide range of products, which are designed to meet the demanding requirements of various applications. Cummins’ dedication to quality and innovation ensures that components like the Tur Oil Drain Tube are engineered to deliver superior performance and durability 8.

Role of the Tur Oil Drain Tube in Engine Systems

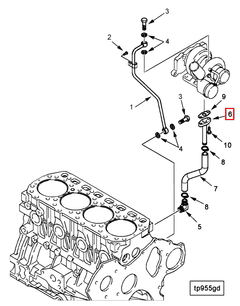

The Tur Oil Drain Tube is an essential component in the maintenance and operation of engine systems, particularly when integrated with plumbing and turbocharger components.

In the context of plumbing, the Tur Oil Drain Tube facilitates the efficient removal of used oil from the engine. This process is vital for maintaining the cleanliness and integrity of the oil system. By ensuring that old oil is effectively drained, the tube helps prevent contamination and buildup, which can otherwise lead to decreased engine performance and potential damage 9.

When considering the turbocharger, the Tur Oil Drain Tube plays a significant role in maintaining the turbocharger’s lubrication system. Turbochargers require a consistent supply of clean oil to function optimally. The drain tube ensures that any excess or contaminated oil is removed from the turbocharger’s oil passages, thereby maintaining the efficiency and longevity of the turbocharger. This is particularly important in high-performance engines where the turbocharger operates under extreme conditions 10.

Overall, the Tur Oil Drain Tube is a key component in ensuring that both the plumbing and turbocharger systems within an engine operate smoothly and efficiently. Its role in facilitating the drainage of used oil contributes to the overall maintenance and performance of the engine system.

Conclusion

The Tur Oil Drain Tube, part number 4900733, is a critical component in the maintenance and operation of heavy-duty truck engines. Its efficient design and durable construction ensure that oil changes are conducted smoothly, contributing to the engine’s overall health and performance. Regular maintenance and proper installation of this part are essential to maximize its benefits and ensure the longevity of the engine system.

-

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ -

Hilgers, M. (2023). Entire Vehicle: Second Edition. Springer Nature.

↩ -

Randall, M. (2015). Haynes Manual on Diesel Engines. Haynes Publishing.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISG12 G CMOH6.0 G111. Bulletin Number 4383874.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISG12 G CMOH6.0 G111. Bulletin Number 4383874.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISG12 G CMOH6.0 G111. Bulletin Number 4383874.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISG12 G CMOH6.0 G111. Bulletin Number 4383874.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISG12 G CMOH6.0 G111. Bulletin Number 4383874.

↩ -

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ -

Randall, M. (2015). Haynes Manual on Diesel Engines. Haynes Publishing.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.