4916288

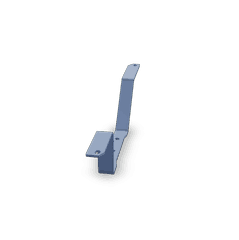

Oil Tube Bracket

Cummins®

AVAILABLE

4 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4916288 Oil Tube Bracket is a component designed to support and secure oil tubes within the engine system of commercial trucks. Its role is significant in maintaining the integrity and efficiency of the oil circulation system, which is vital for the overall operation and longevity of the truck.

Basic Concepts of Oil Tube Brackets

An oil tube bracket serves as a mounting point for oil tubes, ensuring they remain in the correct position and orientation. This bracket plays a role in the engine system by facilitating the secure attachment of oil tubes, which are responsible for transporting oil to various engine components. Proper installation and maintenance of the oil tube bracket contribute to the engine’s performance and reliability by ensuring consistent oil flow and pressure 1.

Purpose of the 4916288 Oil Tube Bracket

The 4916288 Oil Tube Bracket is specifically designed to hold oil tubes in place, ensuring they do not shift or become dislodged during operation. This bracket plays a role in maintaining proper oil flow by securing the tubes, which is crucial for lubricating engine parts, cooling the engine, and ensuring optimal performance. Its function is integral to the engine’s lubrication system, directly impacting the truck’s efficiency and durability 2.

Key Features

The 4916288 Oil Tube Bracket is characterized by its robust design and the use of high-quality materials, which contribute to its durability and performance. It is engineered to withstand the vibrations and stresses associated with heavy-duty truck operations. The bracket’s design allows for easy attachment and detachment of oil tubes, facilitating maintenance and replacement procedures.

Benefits of Using the 4916288 Oil Tube Bracket

Utilizing the 4916288 Oil Tube Bracket offers several advantages, including enhanced engine performance due to secure oil tube placement, increased durability thanks to its sturdy construction, and simplified maintenance processes. The bracket’s design ensures that oil tubes remain in optimal positions, contributing to consistent oil flow and pressure throughout the engine system 3.

Installation Process

Installing the 4916288 Oil Tube Bracket involves several steps to ensure proper setup. First, the engine compartment should be accessed, and the area around the oil tubes should be cleared of any obstructions. The bracket should then be positioned according to the manufacturer’s guidelines, ensuring it is aligned correctly with the oil tubes. Secure the bracket using the provided fasteners, making sure they are tightened to the specified torque settings. Finally, verify the installation by checking for proper oil tube alignment and secure attachment.

Troubleshooting Common Issues

Common issues with oil tube brackets include signs of wear, leaks, and improper installation. Wear can be identified by inspecting the bracket for cracks or deformations, while leaks may indicate a loose connection or damaged oil tube. Improper installation can lead to oil tube misalignment or insufficient securing, affecting oil flow. Addressing these issues involves inspecting the bracket and oil tubes for damage, ensuring all fasteners are tightened correctly, and replacing any worn or damaged components.

Maintenance Tips

Regular maintenance of the 4916288 Oil Tube Bracket is crucial for ensuring its longevity and optimal performance. This includes periodic inspections for signs of wear or damage, cleaning the bracket and surrounding areas to prevent debris accumulation, and verifying the secure attachment of oil tubes. Adhering to recommended inspection intervals and performing routine checks can help identify potential issues before they lead to more significant problems.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s commitment to excellence is reflected in its wide range of products, including the 4916288 Oil Tube Bracket, which is designed to meet the demanding requirements of heavy-duty truck applications.

Oil Tube Bracket 4916288 Compatibility with Cummins Engines

The Oil Tube Bracket part number 4916288, manufactured by Cummins, is designed to fit a variety of Cummins engines. This bracket plays a crucial role in securing the oil tubes, ensuring they remain in place and function correctly. Below is a detailed description of the compatibility of this part with specific Cummins engine models.

GTA38 G CMEICS G116C

The Oil Tube Bracket 4916288 is compatible with the GTA38 G CMEICS G116C engine. This bracket is engineered to fit the specific design and layout of this engine, ensuring that the oil tubes are securely fastened and positioned correctly.

K38, K50, QSK38 CM2150 MCRS, QSK38 CM850 MCRS

The Oil Tube Bracket 4916288 is also suitable for the K38, K50, QSK38 CM2150 MCRS, and QSK38 CM850 MCRS engines. These engines share similar design characteristics, which allows the bracket to be used across these models. The bracket’s design accommodates the specific requirements of these engines, ensuring proper oil tube alignment and stability.

QSK50 CM2150 K107, QSK50 CM2150 MCRS, QSK50 CM2350 K108

For the QSK50 CM2150 K107, QSK50 CM2150 MCRS, and QSK50 CM2350 K108 engines, the Oil Tube Bracket 4916288 is also a perfect fit. These engines, while part of the QSK50 series, have slight variations in their design. The bracket is versatile enough to adapt to these differences, providing a reliable solution for securing the oil tubes in all three models.

This compatibility ensures that the Oil Tube Bracket 4916288 can be used across a range of Cummins engines, providing a consistent and reliable solution for maintaining the integrity of the oil system.

Part 4916288 Oil Tube Bracket Component Usage

The part 4916288 Oil Tube Bracket is an essential component in the Lub Oil Plumbing system, specifically designed to secure and support the Oil Suction Tube. This bracket ensures the tube remains in the correct position and orientation, facilitating efficient Lubricating Oil Suction from the Oil Pan.

In the context of the Oil Suction Mounting system, the Oil Tube Bracket plays a significant role. It provides a stable mounting point for the Oil Suction Tube, which is vital for maintaining the integrity of the oil flow path. This stability is important for consistent oil suction, which in turn supports the overall lubrication needs of the engine.

Additionally, the Oil Tube Bracket interfaces with the Oil Suction Tube Mounting components. By securing the tube, it helps in reducing vibrations and potential wear on the connections, which can otherwise lead to oil leaks or inefficient oil circulation.

Overall, the integration of the Oil Tube Bracket within these systems enhances the reliability and performance of the Lub Oil Plumbing, ensuring that the engine receives a steady supply of lubricating oil. This component is integral to maintaining the operational efficiency of the engine’s lubrication system.

Conclusion

The Cummins 4916288 Oil Tube Bracket is a critical component in the maintenance and efficiency of the oil circulation system in commercial trucks. Its robust design, compatibility with various Cummins engines, and role in securing oil tubes contribute to the overall performance and longevity of the truck. Regular maintenance and proper installation are essential to ensure the bracket’s effectiveness and the engine’s optimal operation.

-

Van Gelder, K. T. (2018). Fundamentals of Automotive Technology Principles and Practice. Jones Bartlett Learning.

↩ -

Stiesch, G. (2003). Modeling Engine Spray and Combustion Processes. Springer Verlag.

↩ -

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.