4917967

Lubricating Oil Transfer Tube

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Lubricating Oil Transfer Tube 4917967 by Cummins is designed to facilitate the efficient transfer of lubricating oil within the lubrication system of commercial trucks. This part ensures that engine components receive the necessary lubrication to operate smoothly and efficiently, thereby maintaining the overall health and performance of the engine 1.

Function and Operation

This Cummins part operates by channeling lubricating oil from the oil reservoir to various engine components that require lubrication, including bearings, pistons, and other moving components. The tube ensures a consistent flow of oil, which helps to reduce friction and wear on these parts. By maintaining adequate lubrication, the tube contributes to the smooth operation and longevity of the engine 2.

Key Features

The Lubricating Oil Transfer Tube 4917967 is constructed from durable materials that can withstand the high temperatures and pressures within the engine compartment. It features precise connection types that ensure a secure fit within the lubrication system. The design includes elements that enhance its durability and efficiency, such as reinforced sections to prevent leaks and ensure a steady flow of oil 3.

Benefits

The advantages provided by the Lubricating Oil Transfer Tube include improved lubrication efficiency, which leads to reduced wear on engine components. This results in enhanced overall engine performance and longevity. By ensuring that oil is distributed effectively throughout the engine, the tube helps to maintain optimal operating conditions and supports the engine’s reliability.

Installation Process

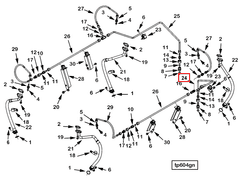

Installing the Lubricating Oil Transfer Tube 4917967 involves several steps to ensure proper integration into the truck’s lubrication system. The process requires specific tools and equipment, and it is recommended to follow manufacturer guidelines for the best results. Key steps include preparing the installation area, connecting the tube to the oil reservoir and engine components, and verifying the connections for leaks or irregularities.

Maintenance and Troubleshooting

To ensure the Lubricating Oil Transfer Tube operates at peak performance, regular maintenance is necessary. This includes inspecting the tube for signs of wear or damage, cleaning it as needed, and addressing any issues such as leaks or blockages promptly. Common troubleshooting techniques involve checking connection points for tightness, ensuring the tube is free from obstructions, and replacing the tube if it shows signs of significant wear or damage.

Safety Considerations

When working with the Lubricating Oil Transfer Tube, it is important to follow safety precautions and guidelines. This includes proper handling procedures to avoid injury, identifying potential hazards such as hot surfaces or moving parts, and having emergency response protocols in place for accidents or spills. Ensuring a safe working environment is paramount when performing maintenance or installation tasks.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its high-quality engine and component offerings. With a rich history of innovation and excellence, Cummins has established a strong reputation for producing reliable and efficient products. The company’s commitment to quality and performance is evident in its wide range of offerings, designed to meet the demanding needs of commercial truck operators.

Cummins Engine Compatibility with Lubricating Oil Transfer Tube (Part 4917967)

The Cummins Lubricating Oil Transfer Tube, part number 4917967, is designed to ensure efficient oil transfer within specific Cummins engine models. This part is integral to maintaining the engine’s lubrication system, which is critical for the longevity and performance of the engine.

QSK60 CM500 and QSK60 CM850 MCRS

The part 4917967 is compatible with the QSK60 CM500 and QSK60 CM850 MCRS engines. These engines are part of Cummins’ QSK60 series, known for their robust design and high performance in various industrial applications. The lubricating oil transfer tube is engineered to fit seamlessly within the architecture of these engines, ensuring that oil is effectively circulated to all necessary components.

Integration and Functionality

In these engines, the lubricating oil transfer tube plays a crucial role in maintaining the oil flow between different parts of the engine. Proper installation and functionality of this part are essential to prevent oil starvation, which can lead to increased friction, overheating, and potential engine failure. The design of the tube ensures that it can withstand the high pressures and temperatures typical of these industrial engines.

Installation Considerations

When installing the lubricating oil transfer tube in the QSK60 CM500 and QSK60 CM850 MCRS engines, it is important to follow the manufacturer’s guidelines to ensure a secure fit. This includes proper alignment and securing of the tube to prevent leaks and maintain the integrity of the engine’s lubrication system. Regular maintenance checks should also be performed to ensure the tube remains in good condition and continues to function as intended.

Role of Part 4917967 Lubricating Oil Transfer Tube in Engine Systems

The 4917967 Lubricating Oil Transfer Tube is an essential component in the efficient operation of engine systems, particularly in the context of plumbing and turbocharger oil management.

In the plumbing system of an engine, this transfer tube facilitates the smooth and consistent flow of lubricating oil from the oil reservoir to various engine components that require lubrication. Its design ensures minimal resistance and efficient oil delivery, which is vital for maintaining the operational integrity of moving parts within the engine. The tube’s placement and connection points are strategically chosen to optimize oil flow and reduce the risk of leaks, thereby enhancing the overall reliability of the engine’s lubrication system.

When it comes to turbocharger oil systems, the 4917967 Lubricating Oil Transfer Tube plays a significant role in ensuring that the turbocharger receives a steady supply of oil. Turbochargers operate under extreme conditions, and consistent lubrication is necessary to prevent wear and tear on the turbocharger’s bearings and other moving parts. The transfer tube is engineered to handle the high pressures and temperatures associated with turbocharger oil systems, ensuring that oil is delivered efficiently even under demanding operating conditions.

Additionally, the tube’s integration into the engine’s oil circulation system allows for effective oil scavenging, which is particularly important in turbocharged engines. This process helps in removing excess oil that may accumulate in the turbocharger, preventing oil starvation and ensuring that the turbocharger operates within its optimal performance range.

In summary, the 4917967 Lubricating Oil Transfer Tube is a key component in maintaining the lubrication needs of both the engine’s general plumbing system and the specialized requirements of turbocharger oil systems. Its reliable performance contributes to the longevity and efficiency of the engine as a whole.

Conclusion

The Lubricating Oil Transfer Tube 4917967 by Cummins is a vital component in the lubrication system of commercial trucks. Its role in ensuring efficient oil transfer and maintaining engine health cannot be overstated. Proper installation, regular maintenance, and adherence to safety guidelines are essential to maximize the benefits of this part and ensure the longevity and performance of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.