This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

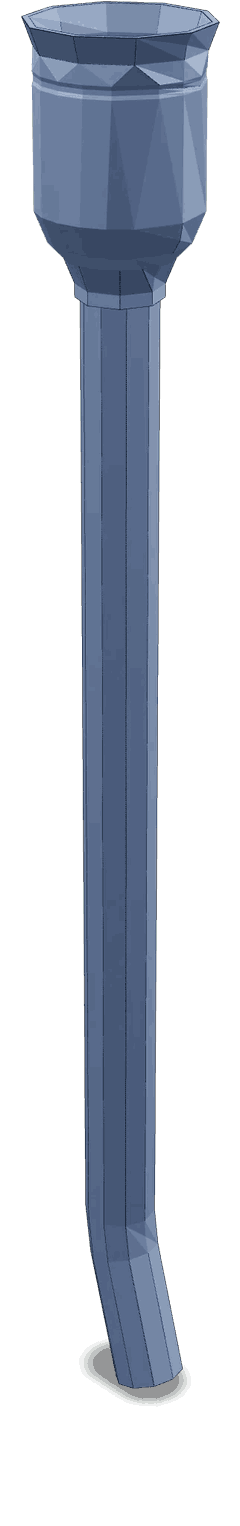

The Cummins 4924572 Oil Gauge Tube is a component designed for use in heavy-duty trucks. Its purpose is to facilitate the accurate measurement of oil levels within the engine, which is significant for maintaining optimal engine performance and longevity. This component is part of Cummins Inc.’s range of automotive parts, known for their reliability and quality 1.

Basic Concepts of Oil Gauge Tubes

An oil gauge tube is a component that allows for the measurement of oil levels within an engine. It functions by providing a pathway for oil to travel from the engine’s oil pan to the oil gauge, where the level can be read. This measurement is important for ensuring that the engine has the appropriate amount of lubrication, which is necessary for reducing friction and wear on moving parts 2.

Purpose of the Cummins 4924572 Oil Gauge Tube

The Cummins 4924572 Oil Gauge Tube plays a role in the operation of a truck by aiding in the accurate measurement of oil levels. This is achieved through its design, which allows oil to flow freely from the oil pan to the gauge. Accurate oil level readings are important for maintaining engine performance, as both low and high oil levels can lead to engine damage 3.

Key Features

The Cummins 4924572 Oil Gauge Tube is characterized by several key features that enhance its functionality. Its design is tailored to fit specific truck models, ensuring a precise fit and function. The materials used in its construction are chosen for their durability and resistance to the harsh conditions found in heavy-duty truck engines. Additionally, any unique attributes, such as reinforced sections or specialized coatings, contribute to its overall effectiveness 4.

Benefits of Using the Cummins 4924572 Oil Gauge Tube

Utilizing the Cummins 4924572 Oil Gauge Tube offers several advantages. It provides improved accuracy in oil level readings, which is vital for maintaining engine health. Its durability ensures long-term use, even in demanding environments. Furthermore, its reliability in providing consistent oil level measurements contributes to the overall efficiency and performance of the engine 5.

Installation and Compatibility

Proper installation of the Cummins 4924572 Oil Gauge Tube is important for ensuring its effectiveness. Guidelines for installation include verifying compatibility with the specific truck model to ensure a proper fit. Attention to any specific requirements or considerations during installation will help maintain the integrity of the oil gauge system 6.

Maintenance and Troubleshooting

To ensure the optimal performance of the Cummins 4924572 Oil Gauge Tube, regular maintenance is recommended. This includes checking for any signs of wear or damage and ensuring that the tube is securely in place. Troubleshooting common issues, such as inaccurate readings or leaks, may involve inspecting the tube for blockages or damage and addressing these issues promptly 7.

Cummins Overview

Cummins Inc. is a well-established manufacturer in the automotive industry, with a history of producing high-quality components. The company’s reputation is built on its commitment to innovation, quality, and customer satisfaction. Cummins components, including the 4924572 Oil Gauge Tube, are designed with these principles in mind, ensuring they meet the high standards expected in the industry 8.

Conclusion

The Cummins 4924572 Oil Gauge Tube is a vital component in the maintenance and operation of heavy-duty truck engines. Its accurate measurement of oil levels ensures optimal engine performance and longevity. With its durable construction and reliable functionality, this Cummins part is a testament to the company’s commitment to quality and innovation in automotive engineering.

-

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩ -

Gifford, C. (2014). Cars Encyclopedia. DK Publishing.

↩ -

Smil, V. (2010). The History and Impact of Diesel Engines and Gas Turbines. The MIT Press.

↩ -

Reif, K. (Ed.). (2014). Diesel Engine Management Systems and Components. Springer Vieweg.

↩ -

Barton, D. C., & Fieldhouse, J. D. (2009).

↩ -

Gifford, C. (2014).

↩ -

Reif, K. (Ed.). (2014).

↩ -

Smil, V. (2010).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.