This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Turbo Oil Drain Tube (Part #4967696) by Cummins is a component designed to facilitate the efficient drainage of oil from the turbocharger in heavy-duty truck engines. Manufactured by Cummins Inc., a leader in the automotive industry known for its commitment to innovation and quality, this part plays a significant role in maintaining the performance and longevity of turbochargers in demanding engine environments.

Basic Concepts

Turbocharging is a technology that increases an engine’s power output by forcing extra air into the combustion chamber. This process relies on the turbocharger, a device that uses exhaust gases to spin a turbine, which in turn drives a compressor to increase the air supply to the engine. Oil is vital in this system as it lubricates and cools the turbocharger’s moving parts, ensuring smooth operation and preventing overheating. The Turbo Oil Drain Tube is integral to this system, as it allows for the controlled drainage of oil from the turbocharger, maintaining optimal lubrication levels and preventing oil buildup that could lead to inefficiencies or damage 1.

Purpose and Function

The Turbo Oil Drain Tube serves a specific function within the engine’s lubrication system. It facilitates the drainage of oil from the turbocharger, ensuring that the oil level remains within the desired range. This drainage is crucial for maintaining the turbocharger’s efficiency, as it prevents oil from accumulating to a point where it could interfere with the turbocharger’s operation or lead to increased temperatures. By ensuring that oil is efficiently drained, the tube helps in maintaining the turbocharger’s performance and extends its operational life.

Key Features

The Turbo Oil Drain Tube is designed with several key features that enhance its performance and durability. It is constructed from high-quality materials resistant to the high temperatures and pressures found within a turbocharger environment. Its design ensures a secure fit within the engine’s oil system, minimizing the risk of leaks. Additionally, the tube may incorporate features such as reinforced connections or specialized coatings to further enhance its resistance to wear and corrosion, ensuring reliable operation over the engine’s lifespan.

Benefits

Incorporating the Turbo Oil Drain Tube into a truck’s engine system offers several advantages. It contributes to improved turbocharger efficiency by ensuring that the turbocharger operates within optimal lubrication conditions. This, in turn, can lead to enhanced overall engine performance, as the turbocharger is able to maintain its efficiency over a broader range of operating conditions. Furthermore, by facilitating the proper drainage of oil, the tube helps in extending the lifespan of the turbocharger and other related components, reducing the need for frequent maintenance or replacement.

Installation and Compatibility

Proper installation of the Turbo Oil Drain Tube is crucial for its effective operation. Installation procedures should follow manufacturer guidelines to ensure that the tube is securely fitted and properly aligned within the engine’s oil system. Compatibility with specific engine models is an important consideration, as the tube must be designed to fit the unique configurations of different turbochargers and engine layouts. Cummins provides detailed information on compatible engine models and any specific requirements for integrating the tube into various truck makes and models.

Maintenance and Troubleshooting

Routine maintenance of the Turbo Oil Drain Tube is relatively straightforward but important for ensuring its continued effective operation. Regular inspections for signs of wear, corrosion, or leaks are recommended, along with ensuring that all connections are secure and free from debris. Troubleshooting common issues, such as leaks or blockages, may involve checking for proper alignment and fit within the engine’s oil system, as well as inspecting for damage or deterioration of the tube itself. Addressing these issues promptly can help in maintaining the turbocharger’s efficiency and preventing more significant engine problems.

Common Failure Modes

Typical failure modes associated with the Turbo Oil Drain Tube include leaks, blockages, and material degradation. Leaks can occur due to improper installation, wear, or damage to the tube, leading to oil loss and potential turbocharger damage. Blockages may result from debris or sludge accumulation within the tube, impeding oil flow and affecting turbocharger lubrication. Material degradation, caused by exposure to high temperatures and pressures, can weaken the tube, increasing the risk of failure. Understanding these failure modes and their potential causes can aid in preventing issues and ensuring the turbocharger’s reliable operation.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history spanning over a century, Cummins is renowned for its innovation, quality, and commitment to customer satisfaction. The company’s extensive product portfolio serves various industries, from automotive to industrial and power generation, demonstrating its versatility and expertise in power technology. Cummins’ dedication to advancing technology and improving efficiency is evident in its products, including the Turbo Oil Drain Tube, which exemplifies the company’s focus on enhancing engine performance and reliability.

Compatibility

The Turbo Oil Drain Tube (4967696) is compatible with several Cummins engine models, including the V903 engine series, which is known for its robust performance and reliability. This part is essential for the V903 engines, as it helps prevent oil accumulation within the turbocharger, which can lead to overheating and potential damage. The V903 engines are typically used in heavy-duty applications, where the efficiency and longevity of the turbocharger are paramount.

Role in Engine Systems

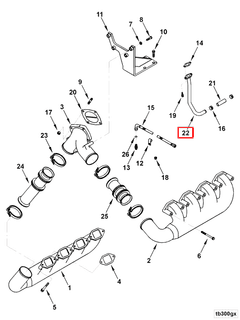

The Turbo Oil Drain Tube, part 4967696, is integral to the efficient operation and maintenance of engine systems, particularly in configurations involving turbochargers. This component facilitates the drainage of oil from the turbocharger, ensuring that the lubrication system remains effective and that oil does not accumulate to problematic levels.

In the context of a turbocharger arrangement, the Turbo Oil Drain Tube is positioned to connect the turbocharger with the oil return system of the engine. Its primary function is to allow excess oil, which has been used for lubricating the turbocharger’s moving parts, to be efficiently returned to the engine’s oil sump. This process is essential for maintaining the correct oil level within the turbocharger and preventing oil starvation or over-lubrication, both of which can adversely affect performance and longevity.

When considering the turbocharger mounting, the Turbo Oil Drain Tube must be correctly aligned and secured. Proper installation ensures that oil drainage occurs without leaks, which could lead to oil contamination or loss. The tube’s connection points are typically designed to match the specific contours and requirements of the turbocharger and its mounting brackets, facilitating a secure and leak-proof fit.

Overall, the Turbo Oil Drain Tube plays a significant role in the maintenance and operational integrity of turbocharged engine systems. Its correct installation and function are essential for the sustained performance and reliability of the turbocharger and the engine as a whole.

Conclusion

The Turbo Oil Drain Tube (Part #4967696) by Cummins is a critical component in the maintenance and operation of turbocharged engine systems. Its role in facilitating the efficient drainage of oil from the turbocharger ensures optimal lubrication conditions, enhances engine performance, and extends the lifespan of the turbocharger. Proper installation, maintenance, and understanding of common failure modes are essential for maximizing the benefits of this part.

-

Reif, Konrad, ed. Brakes Brake Control and Driver Assistance Systems Function Regulation and Components. Springer, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.