This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

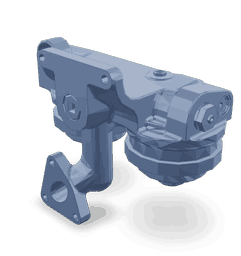

The Lubricating Oil Filter Head 4970125 is a component designed to facilitate the filtration of engine oil in heavy-duty trucks. This part is integral to the engine lubrication system, ensuring that the oil circulating through the engine remains clean and free from contaminants. Cummins, a well-established manufacturer in the heavy-duty truck industry, produces this filter head, leveraging its expertise to deliver reliable and efficient components for truck engines 3.

Basic Concepts of Lubricating Oil Filter Heads

A Lubricating Oil Filter Head is an essential element within the engine lubrication system. Its primary function is to house the oil filter and enable the flow of oil through the filtration process. By filtering out impurities and contaminants from the engine oil, it helps maintain the engine’s performance and longevity. Clean oil ensures that engine components operate smoothly, reducing wear and tear and enhancing overall engine efficiency 4.

Purpose of the 4970125 Lubricating Oil Filter Head

The 4970125 Lubricating Oil Filter Head plays a specific role in the operation of a truck by facilitating the filtration of contaminants from the engine oil. This process is vital for maintaining the engine’s health, as clean oil is essential for lubricating moving parts, cooling the engine, and carrying away debris. The filter head ensures that the oil filter is securely in place and that oil flows efficiently through the system, contributing to the engine’s reliable performance 1.

Key Features

The 4970125 Lubricating Oil Filter Head is designed with several key features that enhance its performance. It is constructed from durable materials to withstand the high pressures and temperatures of the engine environment. The design includes precise fittings and seals to ensure a secure connection to the engine and the oil filter. Additionally, it may feature unique attributes such as anti-drainback valves to prevent oil loss when the engine is turned off, ensuring that the engine is lubricated immediately upon startup 2.

Benefits

Using the 4970125 Lubricating Oil Filter Head offers several benefits. It contributes to improved engine efficiency by ensuring that the oil remains clean and free from contaminants. This cleanliness helps reduce friction between moving parts, leading to smoother operation and potentially lower fuel consumption. Moreover, by maintaining the quality of the engine oil, this filter head aids in prolonging the engine’s life, offering reliable performance under various operating conditions 3.

Installation Process

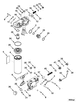

Installing the 4970125 Lubricating Oil Filter Head requires careful attention to ensure a secure fit. The process involves removing the old filter head, if present, and cleaning the mounting surface. The new filter head should be aligned with the engine’s fittings and secured according to the manufacturer’s instructions. Tools such as wrenches may be required to tighten connections properly. Following best practices during installation, such as applying a light coat of oil to seals, can help ensure a leak-free connection 1.

Maintenance Tips

Regular maintenance of the 4970125 Lubricating Oil Filter Head is crucial for ensuring optimal performance. This includes inspecting the filter head for signs of wear or damage during routine oil changes and replacing it according to the manufacturer’s recommendations. Cleaning the mounting surface and checking connections for leaks can also help maintain the efficiency of the lubrication system. Adhering to these maintenance practices can contribute to the longevity and reliability of the engine 4.

Troubleshooting Common Issues

Common issues with the 4970125 Lubricating Oil Filter Head may include leaks or reduced filtration efficiency. Leaks can often be traced to improper installation or worn seals, while reduced efficiency might indicate a clogged filter or contamination within the system. Troubleshooting steps may involve inspecting the filter head and connections for damage, ensuring the filter is correctly installed, and replacing the filter or filter head if necessary. Regular maintenance can help prevent many of these issues 2.

Cummins Lubricating Oil Filter Head 4970125 Compatibility

The Cummins Lubricating Oil Filter Head, part number 4970125, is a critical component in the maintenance and operation of several Cummins engine models. This part is designed to ensure the proper filtration of lubricating oil, which is essential for the longevity and efficiency of the engine.

K19 Engines

The K19 engine series benefits from the use of the 4970125 oil filter head. This part is engineered to fit seamlessly into the K19’s oil system, providing a reliable seal and ensuring that contaminants are effectively filtered out of the oil. The compatibility of this part with the K19 engine ensures that the engine operates smoothly and efficiently 3.

QSK19 Engines

Similarly, the QSK19 engine series is another beneficiary of the 4970125 oil filter head. This part is designed to integrate with the QSK19’s oil system, offering a robust and dependable solution for oil filtration. The use of this oil filter head in the QSK19 engine helps maintain optimal engine performance and extends the engine’s service life 4.

CM850 Engines

The CM850 engine also utilizes the 4970125 oil filter head. This part is specifically designed to fit the CM850’s oil system, ensuring that the engine’s oil remains clean and free of contaminants. The compatibility of this oil filter head with the CM850 engine is crucial for maintaining the engine’s efficiency and reliability 1.

MCRS Engines

Lastly, the MCRS engine series is another application for the 4970125 oil filter head. This part is engineered to fit the MCRS’s oil system, providing a secure and effective filtration solution. The use of this oil filter head in the MCRS engine helps to ensure that the engine operates at peak performance and durability 2.

By ensuring that the 4970125 oil filter head is used in these engines, maintenance personnel can be confident that the oil system is protected, leading to improved engine performance and longevity.

Role of Part 4970125 Lubricating Oil Filter Head in Engine Systems

The 4970125 Lubricating Oil Filter Head is an integral component in the maintenance and efficiency of engine systems. It is specifically designed to interface with the lubricating oil filter, ensuring that the oil circulating within the engine is clean and free from contaminants.

This component facilitates the connection between the engine’s lubrication system and the oil filter. As oil is pumped from the sump, it passes through the 4970125 head into the filter where impurities are trapped. The clean oil then continues its journey through the engine, providing necessary lubrication to moving parts, reducing friction, and preventing wear.

In addition to its primary function, the 4970125 head also plays a role in maintaining the pressure within the lubrication system. It is equipped with a pressure relief valve that opens if the pressure within the filter becomes too high, preventing damage to the filter or the lubrication system.

Furthermore, the 4970125 head is designed with an anti-drainback valve. This valve ensures that oil does not drain back into the sump when the engine is turned off, which helps to maintain oil pressure and provides immediate lubrication when the engine is restarted.

In summary, the 4970125 Lubricating Oil Filter Head is a key component in the efficient operation of an engine’s lubrication system. It ensures that the oil remains clean, maintains system pressure, and provides immediate lubrication upon engine start-up 3.

Conclusion

The 4970125 Lubricating Oil Filter Head by Cummins is a vital component in the maintenance and efficiency of heavy-duty truck engines. Its role in ensuring clean oil circulation, maintaining system pressure, and providing immediate lubrication upon engine start-up underscores its importance in engine systems. Regular maintenance and proper installation are essential to maximize the benefits of this part, contributing to the longevity and reliable performance of the engine 4.

-

Sean Bennett, Ian Andrew Norman, Heavy Duty Truck Systems Fifth Edition, Delmar Cengage Learning, 2011.

↩ ↩ ↩ -

Michael Hilgers and Wilfried Achenbach, Vocational Vehicles and Applications, Springer Vieweg, 2021.

↩ ↩ ↩ -

Saiful Bari, Diesel Engine Combustion, Emissions and Condition Monitoring, InTech, 2013.

↩ ↩ ↩ ↩ -

Richard D. Atkins, An Introduction to Engine Testing and Development, SAE International, 2009.

↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.