This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

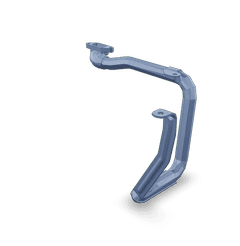

The Lubricating Oil Suction Tube, identified by Part #4993358, is a component manufactured by Cummins, a leading name in the automotive and heavy-duty truck industries. This part is integral to the lubrication system of heavy-duty trucks, ensuring that the engine operates smoothly and efficiently by facilitating the proper circulation of lubricating oil 1.

Basic Concepts

Lubrication is a fundamental principle in the operation of internal combustion engines. It involves the use of oil to reduce friction between moving parts, which helps to minimize wear and tear, dissipate heat, and remove contaminants 2. Maintaining proper oil levels and ensuring consistent oil flow are vital for the longevity and performance of the engine.

Function and Operation

The Lubricating Oil Suction Tube plays a specific role within the lubrication system. It is responsible for drawing oil from the sump, where the oil is stored, and delivering it to the oil pump. This process ensures a continuous supply of oil is available for circulation throughout the engine, supporting the lubrication of critical components 3.

Purpose of the Lubricating Oil Suction Tube

In the context of heavy-duty trucks, the Lubricating Oil Suction Tube contributes to the efficient circulation of oil and the overall lubrication of the engine. Its design and placement within the system are tailored to support the high demands of heavy-duty applications, ensuring that the engine remains well-lubricated under various operating conditions.

Key Features

The Lubricating Oil Suction Tube is designed with specific features that enhance its performance and durability. These include its material composition, which is selected for resistance to wear and corrosion, and its dimensions, which are optimized for efficient oil flow. Additionally, any unique characteristics of the tube, such as reinforced sections or specialized coatings, contribute to its effectiveness in the lubrication system.

Benefits

The advantages offered by the Lubricating Oil Suction Tube include improved oil flow, which supports consistent lubrication across the engine. It also helps reduce the risk of cavitation, a condition where vapor bubbles form in the oil due to low pressure, potentially leading to engine damage. Furthermore, by ensuring a steady supply of oil, the tube enhances engine protection against wear and damage, contributing to the overall reliability and performance of the vehicle.

Troubleshooting and Maintenance

Common issues related to the Lubricating Oil Suction Tube may include leaks, blockages, or damage. Regular inspection and maintenance are recommended to identify and address these problems promptly. Maintenance practices may involve checking for signs of wear or damage, ensuring connections are secure, and verifying that the tube is free from obstructions. These steps help ensure the optimal performance and longevity of the lubrication system.

Cummins Overview

Cummins Inc. is a well-established company with a significant presence in the automotive and heavy-duty truck industries. Founded with a commitment to innovation and quality, Cummins offers a wide range of products designed to meet the demands of various applications. The company’s reputation for reliability and performance is built on a history of delivering high-quality components and systems, including the Lubricating Oil Suction Tube.

Lubricating Oil Suction Tube (Part 4993358) Compatibility with Cummins Engines

The Cummins part number 4993358, which is a Lubricating Oil Suction Tube, is designed to fit seamlessly with several models of Cummins engines. This part is crucial for the proper functioning of the engine’s lubrication system, ensuring that oil is drawn efficiently from the oil pan to the oil pump.

QSB6.7 CM2250 and QSB6.7 CM2350 B105

The QSB6.7 CM2250 and QSB6.7 CM2350 B105 engines are part of the Cummins QSB series, known for their robust performance and reliability in various applications. The lubricating oil suction tube for these engines is engineered to match the specific design and requirements of these models, ensuring optimal oil flow and pressure. This compatibility is critical for maintaining engine health and performance, as any disruption in oil flow can lead to significant engine damage.

QSB6.7 CM850 (CM2850)

The QSB6.7 CM850, also referred to as CM2850, is another variant in the Cummins QSB series. This engine is designed for applications that require a balance of power and efficiency. The lubricating oil suction tube for the QSB6.7 CM850 is tailored to fit the unique architecture of this engine model, ensuring that the oil is drawn effectively from the oil pan to the oil pump. This part is essential for maintaining the engine’s lubrication system integrity, which is vital for its longevity and performance.

By ensuring that the lubricating oil suction tube is correctly matched with the specific engine model, users can maintain the engine’s performance and reliability, preventing potential issues related to inadequate oil flow.

Role of Part 4993358 Lubricating Oil Suction Tube in Engine Systems

The lubricating oil suction tube, identified by part number 4993358, is integral to the efficient operation of engine systems, particularly in the context of oil management and circulation. This component is designed to facilitate the smooth and consistent flow of oil from the oil pan to the engine’s lubrication system.

Interaction with the Oil Pan

The oil pan serves as the reservoir for the engine’s lubricating oil. It is essential for storing a sufficient volume of oil to ensure continuous lubrication of engine components. The lubricating oil suction tube connects to the oil pan, drawing oil from this reservoir. Its design and placement are optimized to minimize turbulence and ensure a steady flow of oil, which is vital for maintaining consistent oil pressure within the engine.

Ensuring Efficient Oil Circulation

Once the oil is drawn from the oil pan via the suction tube, it is transported to the engine’s lubrication system. This system includes various passages and channels designed to distribute oil to critical engine components such as bearings, pistons, and camshafts. The role of the suction tube in this process is to provide a reliable pathway for oil to travel from the pan to these distribution points, ensuring that all moving parts receive the lubrication they require to operate smoothly and efficiently.

Maintaining Oil Quality

In addition to facilitating oil flow, the lubricating oil suction tube plays a part in maintaining the quality of the oil. By efficiently drawing oil from the pan, it helps prevent the accumulation of contaminants and sludge at the bottom of the pan, which can occur if oil circulation is inadequate. This contributes to the overall cleanliness and effectiveness of the lubrication system, prolonging the life of the engine and enhancing its performance.

Integration with Engine Components

The effective integration of the lubricating oil suction tube with other engine components, such as the oil pump and filtration system, is essential for optimal engine operation. The tube’s design must complement these components to ensure that oil is not only drawn efficiently but also pumped and filtered effectively before being distributed throughout the engine. This seamless integration is key to maintaining the engine’s lubrication system’s integrity and performance.

Conclusion

The Lubricating Oil Suction Tube (Part #4993358) is a critical component in the lubrication system of Cummins engines, ensuring efficient oil circulation and maintaining engine health. Its design and compatibility with specific engine models, such as the QSB6.7 CM2250, QSB6.7 CM2350 B105, and QSB6.7 CM850, are essential for optimal engine performance and reliability. Regular maintenance and proper integration with other engine components are vital for the longevity and efficiency of the lubrication system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.