This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

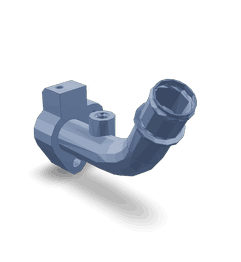

The 5254013 Oil Drain Tube Connection, manufactured by Cummins, is a component designed for use in commercial truck maintenance and operation. Cummins, a well-established name in the industry, produces a range of parts and systems that contribute to the efficiency and reliability of commercial vehicles. This Cummins part is part of this extensive lineup, playing a significant role in the maintenance routines of trucks, particularly in the oil change process.

Basic Concepts of Oil Drain Tube Connection

An Oil Drain Tube Connection is a component that facilitates the draining of oil from an engine. It is typically located at the bottom of the engine’s oil pan and is connected to the oil pan via a threaded fitting. When it is time to change the oil, the connection is unscrewed, allowing the old oil to be drained out of the engine. This process is a fundamental part of engine maintenance, as it ensures that the engine is running on clean oil, which is vital for its performance and longevity 1.

Purpose of the 5254013 Oil Drain Tube Connection

The 5254013 Oil Drain Tube Connection serves a specific function within the operation of a truck. It is designed to provide a secure and efficient means of draining oil from the engine during maintenance routines. By ensuring a reliable connection, it helps in maintaining the integrity of the oil change process, which is crucial for the overall health of the engine. Its design and construction are tailored to withstand the pressures and conditions within the engine compartment, ensuring that it performs its function effectively over time 2.

Key Features

The 5254013 Oil Drain Tube Connection boasts several key features that enhance its performance and durability. It is constructed from high-quality materials that are resistant to corrosion and wear, ensuring longevity even in harsh operating conditions. The design includes a threaded connection that provides a secure fit to the oil pan, minimizing the risk of leaks. Additionally, it may feature unique attributes such as a gasket or O-ring to further ensure a tight seal, contributing to its overall effectiveness in the oil change process.

Benefits

Utilizing the 5254013 Oil Drain Tube Connection offers several benefits. Its design contributes to improved efficiency in oil changes, reducing the time and effort required for maintenance. The durability of the connection means that it can withstand repeated use without degradation, potentially leading to cost savings over time by reducing the need for frequent replacements. Furthermore, its reliable performance helps in maintaining the engine’s efficiency and longevity, contributing to the overall operational effectiveness of the truck.

Installation Process

Installing the 5254013 Oil Drain Tube Connection requires following a series of steps to ensure a secure fit. Begin by ensuring the engine is cool and the oil has been drained. Clean the area around the oil pan to remove any debris. Apply a light coating of oil to the threads of the connection to facilitate installation and prevent seizing. Carefully thread the connection into the oil pan, using a wrench to tighten it securely. It is important to avoid over-tightening, which could damage the threads. Once installed, check for any signs of leaks before refilling the engine with oil.

Troubleshooting Common Issues

Common issues with the 5254013 Oil Drain Tube Connection may include leaks or difficulty in draining. If a leak is detected, it may be necessary to re-tighten the connection or replace the gasket or O-ring. Difficulty in draining could indicate a blockage within the tube, which may require cleaning or replacement of the connection. Regular inspection and maintenance can help identify and address these issues before they lead to more significant problems.

Maintenance Tips

To ensure the longevity and optimal performance of the 5254013 Oil Drain Tube Connection, regular maintenance is recommended. This includes inspecting the connection for signs of wear or damage before each oil change. Cleaning the area around the connection can prevent debris from interfering with the seal. Additionally, checking the tightness of the connection after each use can help maintain a secure fit and prevent leaks.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s extensive product range and commitment to customer satisfaction have made it a preferred choice for commercial vehicle operators and maintenance professionals.

Engine Compatibility with Oil Drain Tube Connection Part 5254013

The Oil Drain Tube Connection part 5254013, manufactured by Cummins, is designed to fit seamlessly with the QSC9 CM2250 and QSL9 CM2250 engines. This part is integral to the engine’s oil management system, ensuring that oil is efficiently drained from the engine’s sump.

For the QSC9 CM2250 and QSL9 CM2250 engines, the Oil Drain Tube Connection part 5254013 is engineered to provide a secure and reliable connection between the oil drain tube and the engine’s oil pan. This connection is crucial for maintaining the engine’s lubrication system, as it allows for the controlled drainage of used oil, facilitating regular maintenance and ensuring the engine operates smoothly.

The design of the part ensures compatibility with both the QSC9 CM2250 and QSL9 CM2250 engines, making it a versatile component that can be used across these engine models. This compatibility is achieved through precise engineering and adherence to Cummins’ stringent quality standards, ensuring that the part fits perfectly and functions optimally within the engine’s design parameters.

By using the Oil Drain Tube Connection part 5254013, engine operators can benefit from a reliable and efficient oil drainage system, contributing to the overall performance and longevity of the QSC9 CM2250 and QSL9 CM2250 engines.

Role of Part 5254013 Oil Drain Tube Connection in Engine Systems

The Part 5254013 Oil Drain Tube Connection is integral to the efficient functioning of several engine systems, particularly in the context of auxiliary pump plumbing and oil drain connections.

Integration with Auxiliary Pump Plumbing

In systems where an auxiliary pump is employed, the Oil Drain Tube Connection ensures a seamless interface between the primary oil system and the auxiliary pump. This connection facilitates the return flow of oil from the auxiliary pump back into the main oil reservoir, maintaining a balanced oil circulation. It is designed to handle the increased oil flow rates and pressures associated with auxiliary pump operations, ensuring that the oil system remains efficient and reliable.

Function in Oil Drain Systems

The Oil Drain Tube Connection plays a significant role in the oil drain system by providing a secure and leak-proof connection point for the oil drain tube. This is essential for the periodic draining of oil from the engine, a maintenance procedure that is vital for the longevity and performance of the engine. The connection ensures that the oil is efficiently channeled away from the engine, preventing any potential contamination or spillage.

Enhanced System Reliability

By integrating the Oil Drain Tube Connection into these systems, engineers and mechanics can enhance the overall reliability of the engine. The connection is designed to withstand the operational stresses and environmental conditions typical in engine compartments, ensuring that the oil management systems function without interruption.

Maintenance and Serviceability

The design of the Oil Drain Tube Connection also considers ease of maintenance and serviceability. It allows for quick and straightforward disconnection and reconnection of the oil drain tube, facilitating routine maintenance tasks and reducing downtime. This feature is particularly beneficial in high-demand applications where rapid turnaround times are essential.

Conclusion

In summary, the Part 5254013 Oil Drain Tube Connection is a key component in maintaining the integrity and efficiency of auxiliary pump plumbing and oil drain systems within engine applications. Its robust design and reliable performance make it an indispensable part of modern engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.