5266064

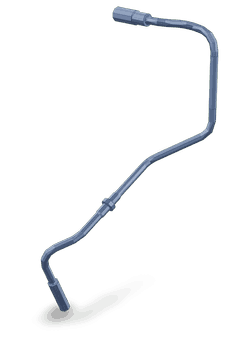

Lubricating Oil Drain Tube

Cummins®

DISCONTINUED

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Lubricating Oil Drain Tube (Part #5266064) by Cummins is a component designed for the maintenance of commercial trucks. It facilitates the draining of used oil from the engine, which is a routine part of vehicle maintenance. This tube ensures that the process of oil change is efficient and straightforward, contributing to the overall upkeep and performance of the truck.

Basic Concepts of Lubricating Oil Drain Tubes

Lubricating oil drain tubes are integral to the engine system, primarily responsible for the removal of used oil. Regular oil changes are important for maintaining engine health, as they remove contaminants and degraded oil that can impair engine performance. The drain tube plays a role in this process by providing a pathway for the oil to exit the engine, ensuring that the process is clean and efficient 1.

Purpose and Function

The Lubricating Oil Drain Tube serves a specific role in the operation of a truck. It aids in the efficient draining of used oil, which is important for maintaining engine lubrication and optimal performance. By ensuring that old oil is removed effectively, the tube helps in maintaining the engine’s efficiency and longevity 2.

Key Features

The design and construction of the Lubricating Oil Drain Tube (Part #5266064) include several features that enhance its functionality. These may encompass specific material compositions for durability, precise threading specifications for secure fitting, and unique design elements that facilitate easy installation and removal.

Benefits

Using the Cummins Lubricating Oil Drain Tube offers several advantages. These include contributing to improved engine longevity through efficient oil changes, simplifying maintenance procedures, and providing reliability under various operating conditions. The tube’s design and construction are tailored to meet the demanding requirements of commercial truck engines 3.

Installation Process

Installing the Lubricating Oil Drain Tube requires following a specific procedure to ensure proper fitting and function. This process may involve using certain tools and observing safety precautions to prevent damage to the engine or injury to the installer.

Troubleshooting Common Issues

Common issues with lubricating oil drain tubes can include leaks, blockages, and threading problems. Addressing these issues effectively requires understanding the symptoms and applying practical solutions, such as tightening connections, clearing blockages, or replacing damaged components.

Maintenance Tips

Regular maintenance of the Lubricating Oil Drain Tube is important for its longevity and optimal performance. This may involve cleaning the tube, inspecting it for wear or damage, and knowing when to consider replacement to prevent potential issues during oil changes.

Cummins: A Brief Overview

Cummins Inc. is a well-established company in the automotive industry, known for its wide range of products and commitment to innovation. The company provides high-quality components for commercial vehicles, including the Lubricating Oil Drain Tube, reflecting its dedication to enhancing vehicle performance and reliability.

Role of Part 5266064 Lubricating Oil Drain Tube in Engine Systems

This part is an essential component in the efficient operation of various engine systems. It is specifically designed to facilitate the draining of lubricating oil from the crankcase, ensuring that the oil can be regularly replaced or checked without causing contamination or spillage.

Integration with the Crankcase

In the crankcase, this Cummins part plays a significant role in maintaining the integrity of the lubrication system. By providing a controlled pathway for oil to exit the crankcase, it helps in preventing oil buildup which could lead to increased pressure and potential leaks. This is particularly important in high-performance engines where oil management is key to engine longevity and performance.

Function within the Long Block

When considering the long block—which includes the cylinder block, crankshaft, pistons, and other essential components—the lubricating oil drain tube ensures that the oil change process is streamlined. This is vital for maintaining the lubrication of moving parts, reducing friction, and enhancing the overall efficiency of the engine. Regular oil changes facilitated by the drain tube help in removing contaminants that accumulate over time, thus protecting the long block components from wear and tear.

Interaction with the Breather System

The breather system is designed to allow air to escape from the crankcase as the pistons move up and down. The lubricating oil drain tube works in conjunction with the breather to maintain a balanced pressure environment within the crankcase. This interaction ensures that the breather system functions optimally, allowing for the safe release of gases without the risk of oil being forced out, which could lead to oil loss and potential environmental hazards.

Conclusion

In summary, the 5266064 Lubricating Oil Drain Tube is a vital component that enhances the functionality and maintenance of engine systems by ensuring efficient oil drainage, supporting the breather system, and contributing to the overall health of the crankcase and long block.

-

Robinson, A., & Livesey, A. (2006). The Repair of Vehicle Bodies Fifth Edition. Elsevier.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2019). Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.