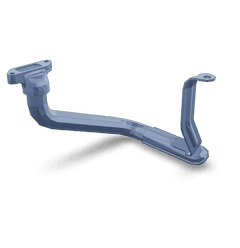

5274750

Lubricating Oil Suction Tube

Cummins®

IN STOCK

3 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Lubricating Oil Suction Pipe, identified by Part #5274750, is a component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industry. This pipe is integral to the engine lubrication system, facilitating the efficient circulation of oil to ensure the smooth operation and longevity of engine components.

Function and Operation

The Lubricating Oil Suction Pipe operates within the engine lubrication system by drawing oil from the sump and delivering it to the oil pump. This process is fundamental to maintaining a consistent supply of lubricant to critical engine parts, ensuring they function optimally under various operating conditions 1.

Purpose of the Lubricating Oil Suction Pipe

The specific role of the Lubricating Oil Suction Pipe (Part #5274750) in a truck’s operation is to maintain proper lubrication of engine components. By ensuring a steady flow of oil from the sump to the oil pump, it helps in reducing friction and wear between moving parts, contributing to the overall efficiency and durability of the engine 2.

Key Features

The Lubricating Oil Suction Pipe is constructed from high-quality materials designed to withstand the harsh conditions within an engine. Its design includes features such as reinforced connections and a smooth interior to enhance oil flow efficiency. Additionally, the pipe may incorporate unique characteristics like anti-corrosion coatings or specialized fittings to improve performance and durability.

Benefits

Utilizing the Lubricating Oil Suction Pipe in heavy-duty truck engines offers several benefits. These include improved lubrication efficiency, which leads to enhanced engine performance and prolonged engine life. The pipe’s design and material construction contribute to these advantages by ensuring a reliable and efficient oil supply to the engine’s critical components 3.

Installation Considerations

When installing the Lubricating Oil Suction Pipe, it is important to follow guidelines and best practices to ensure optimal performance. This includes proper fitting, sealing, and alignment of the pipe to prevent oil leaks and ensure efficient oil flow. Careful attention to these details during installation can significantly impact the engine’s lubrication system effectiveness.

Troubleshooting Common Issues

Common problems associated with the Lubricating Oil Suction Pipe may include oil leaks, blockages, or reduced oil flow. Troubleshooting these issues involves identifying the source of the problem, whether it be a faulty connection, debris in the pipe, or wear and tear. Recommended solutions may include tightening connections, cleaning the pipe, or replacing damaged sections to restore proper function.

Maintenance Tips

To ensure the longevity and efficiency of the Lubricating Oil Suction Pipe, regular maintenance is recommended. This includes inspecting the pipe for signs of wear or damage, cleaning it to remove any debris that may obstruct oil flow, and replacing it according to manufacturer guidelines or when signs of significant wear are observed. These practices help maintain the integrity of the engine lubrication system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, related technologies, and services. With a history of innovation and a strong reputation in the automotive and heavy-duty truck industry, Cummins is known for its commitment to quality, performance, and customer satisfaction. The company’s product range includes engines, filtration systems, and aftermarket parts, all designed to meet the demanding requirements of various applications.

Cummins Engine Compatibility with Lubricating Oil Suction Pipe Part 5274750

The Cummins Lubricating Oil Suction Pipe part number 5274750 is designed to fit a variety of Cummins engines, ensuring efficient oil flow and system integrity. Here is a detailed look at the compatibility of this part with various Cummins engines:

B6.7 Series

- B6.7 CM2350 B135B

- B6.7 CM2670 B153B

- B6.7 CM2670 B164C

- B6.7 G CMOH6.0 B125

The B6.7 series engines, including the B6.7 CM2350 B135B, B6.7 CM2670 B153B, B6.7 CM2670 B164C, and B6.7 G CMOH6.0 B125, are compatible with the part number 5274750. This ensures that the oil suction pipe fits seamlessly, maintaining the engine’s lubrication system efficiency.

ISB Series

- ISB CM2150

- ISB/ISD6.7 CM2150 SN

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

- ISB6.7 G CM2180 B118

The ISB series engines, including the ISB CM2150, ISB/ISD6.7 CM2150 SN, ISB6.7 CM2250, ISB6.7 CM2350 B101, and ISB6.7 G CM2180 B118, are also compatible with the 5274750 oil suction pipe. This compatibility ensures that the oil flow is maintained, which is crucial for the engine’s performance and longevity.

ISBE Series

- ISBE CM2150

- ISBE4 CM850

The ISBE series engines, such as the ISBE CM2150 and ISBE4 CM850, are designed to work with the 5274750 oil suction pipe. This compatibility is essential for maintaining the proper lubrication flow in these engines.

QSB Series

- QSB6.7 CM2250

- QSB6.7 CM2350 B105

- QSB6.7 CM850 (CM2850)

- QSB6.7 M CM2250

- QSB7 CM2880 B117

The QSB series engines, including the QSB6.7 CM2250, QSB6.7 CM2350 B105, QSB6.7 CM850 (CM2850), QSB6.7 M CM2250, and QSB7 CM2880 B117, are also compatible with the 5274750 oil suction pipe. This compatibility ensures that the oil suction pipe fits these engines, maintaining the necessary lubrication flow for optimal engine performance.

By ensuring compatibility with these various Cummins engines, the 5274750 oil suction pipe provides a reliable solution for maintaining the engine’s lubrication system.

Conclusion

The Lubricating Oil Suction Pipe (Part #5274750) by Cummins is a critical component in the engine lubrication system, ensuring the efficient circulation of oil to maintain engine performance and longevity. Its compatibility with a wide range of Cummins engines underscores its importance in the automotive and heavy-duty truck industry. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.