5289815

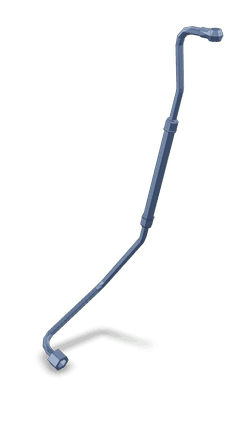

Turbo Oil Supply Tube

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Turbo Oil Supply Tube, identified by Part #5289815, is a component manufactured by Cummins, a well-established name in the automotive industry. This part is integral to the operation of heavy-duty truck engines, particularly those equipped with turbochargers. Its role in the lubrication system ensures the efficient and reliable performance of the turbocharger, contributing to the overall functionality and longevity of the engine.

Basic Concepts and Functionality

The Turbo Oil Supply Tube operates within the lubrication system of turbocharged engines. Its primary function is to deliver oil to the turbocharger, ensuring that all moving parts within the turbocharger are adequately lubricated. This lubrication is vital for reducing friction, dissipating heat, and preventing wear on the turbocharger components. The tube interacts with the engine’s oil supply system, drawing oil from the sump and directing it to the turbocharger. This process is continuous while the engine is running, highlighting the tube’s role in maintaining the turbocharger’s operational integrity 1.

Purpose and Role in Truck Operation

In the context of heavy-duty trucks, the Turbo Oil Supply Tube plays a significant role in maintaining turbocharger performance and longevity. By ensuring a consistent supply of oil to the turbocharger, the tube helps to maintain optimal operating conditions. This consistent lubrication is key to preventing overheating, reducing wear, and ensuring that the turbocharger can operate efficiently under the demanding conditions typical of heavy-duty truck use. The tube’s role in this system is fundamental to the truck’s overall performance, contributing to both engine efficiency and reliability 2.

Key Features

The Turbo Oil Supply Tube is designed with several key features that enhance its performance and durability. It is typically made from high-quality materials that can withstand the high temperatures and pressures present in the engine compartment. The design of the tube includes precise fittings and connections to ensure a secure and leak-free installation. Additionally, the tube may incorporate features such as reinforced sections to prevent kinking or damage, ensuring a reliable oil supply to the turbocharger 3.

Benefits

The advantages provided by the Turbo Oil Supply Tube are significant. Improved engine efficiency is one of the primary benefits, as proper lubrication of the turbocharger leads to reduced friction and heat, allowing the engine to operate more smoothly and with greater fuel efficiency. Reduced wear on turbocharger components is another key benefit, as consistent lubrication prevents the premature degradation of parts, extending the turbocharger’s lifespan. Enhanced overall reliability of the truck’s powertrain is also a notable advantage, as the tube’s role in maintaining turbocharger performance contributes to the engine’s durability and performance under heavy-duty conditions 4.

Installation and Compatibility

Proper installation of the Turbo Oil Supply Tube is crucial for ensuring its effectiveness and the overall performance of the turbocharger. Installation procedures may vary slightly depending on the specific truck model and engine configuration, but generally involve connecting the tube to the engine’s oil supply system and securing it in place within the engine compartment. It is important to follow manufacturer guidelines to ensure compatibility and proper function. Specific requirements or considerations may include ensuring the correct orientation of the tube, using the appropriate fasteners, and verifying that all connections are secure and leak-free.

Troubleshooting and Maintenance

Common issues that may arise with the Turbo Oil Supply Tube include leaks, blockages, or damage to the tube itself. Diagnostic procedures for identifying problems may involve visual inspection for leaks or damage, checking oil pressure to ensure consistent flow, and monitoring turbocharger performance for signs of inadequate lubrication. Recommended maintenance practices include regular inspection of the tube and connections for signs of wear or damage, ensuring that all fittings are secure, and replacing the tube if any issues are detected. These practices help to ensure optimal performance and longevity of the turbocharger and the engine as a whole.

Cummins Overview

Cummins Inc. is a globally recognized leader in the design, manufacture, and distribution of diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the automotive industry. The company’s commitment to manufacturing high-quality components for heavy-duty trucks is evident in its extensive range of products, including the Turbo Oil Supply Tube. Cummins’ focus on engineering excellence and customer satisfaction underscores its position as a trusted provider of automotive components.

Conclusion

The Turbo Oil Supply Tube (5289815) is a vital component in the lubrication system of turbocharged engines, ensuring the efficient and reliable operation of the turbocharger. Its role in reducing friction, dissipating heat, and preventing wear on turbocharger components contributes significantly to the overall performance and longevity of heavy-duty truck engines. Proper installation, maintenance, and troubleshooting are essential for maximizing the benefits of this Cummins part.

-

Schuetz, T. (2016). Aerodynamics of Road Vehicles: Fifth Edition. SAE International.

↩ -

Smil, V. (2010). The History and Impact of Diesel Engines and Gas Turbines. The MIT Press.

↩ -

Minaker, B. P. (2019). Fundamentals of Vehicle Dynamics and Modelling. John Wiley Sons.

↩ -

Gilles, T. (2020). Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.