This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 5291655 Oil Filler Tube is a component designed for use in heavy-duty trucks. It facilitates the addition of oil to the engine, ensuring proper lubrication for efficient and reliable operation.

Purpose and Function

This Cummins part plays a role in the lubrication system by allowing for the addition of oil. It ensures that the engine maintains optimal lubrication levels, which is necessary for reducing friction between moving parts, dissipating heat, and preventing wear and tear 1.

Key Features

The 5291655 is constructed with high-quality materials that enhance its durability and performance. It is designed to withstand the rigors of heavy-duty truck operation. The tube features a robust construction that ensures it can handle the pressure and temperature variations within the engine compartment 2. Additionally, its design may include features such as a secure fitting mechanism to prevent leaks and ensure a tight seal during operation.

Benefits

Using this part offers several advantages. It contributes to improved engine performance by ensuring consistent and adequate lubrication. The design of the tube makes it easy to use during oil changes, reducing the time and effort required for maintenance. Furthermore, by maintaining proper lubrication levels, the tube helps enhance the overall reliability and longevity of the truck’s engine 3.

Installation and Usage

Proper installation of the 5291655 involves several steps. First, ensure that the engine is cool and the oil has been drained. Then, locate the oil filler neck on the engine and align the tube with the fitting. Secure the tube in place using the provided fasteners, ensuring a tight seal. During routine maintenance, such as oil changes, simply unscrew the tube to add new oil, following the manufacturer’s recommendations for the type and quantity of oil to use.

Troubleshooting and Maintenance

Common issues with the Oil Filler Tube may include leaks or difficulty in securing the tube during installation. To address leaks, inspect the tube and fitting for any damage or misalignment. Ensure that all fasteners are tightened properly. Regular maintenance involves checking the tube for signs of wear or corrosion and replacing it if necessary to prevent potential issues.

Safety Considerations

When working with the 5291655, it is important to follow safety guidelines. Always allow the engine to cool before attempting any maintenance to avoid burns from hot oil or engine components. Ensure that the tube is properly sealed to prevent oil leaks, which can create a hazardous condition. Use caution when handling tools and equipment to avoid injury.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins serves customers in approximately 190 countries and territories through a network of company-owned and independent distributor facilities and dealerships. The company is committed to delivering reliable and efficient power solutions across various industries, including transportation, construction, and power generation.

Compatibility

The 5291655 is designed to fit seamlessly with several engine models, ensuring optimal engine performance and maintenance. This part is integral to the engine’s oil system, facilitating the addition of oil and providing a clear view of the oil level.

Compatible Engines

- QSB3.3 CM2250 EC

- QSB6.7 CM2350 EC

- QSC6.7 CM2350 EC

These engines, part of the Cummins QSB and QSC series, are known for their robust design and reliability in various applications, from industrial to marine use. The Oil Filler Tube is engineered to match the specific design and requirements of these engines, ensuring a precise fit and function.

Engine Grouping

The 5291655 is compatible with the following engine groups:

-

QSB Series

- QSB3.3 CM2250 EC

- QSB6.7 CM2350 EC

-

QSC Series

- QSC6.7 CM2350 EC

These groupings are based on the engine’s architecture and the shared design elements that allow the Oil Filler Tube to fit and function correctly across the specified models.

Role in Engine Systems

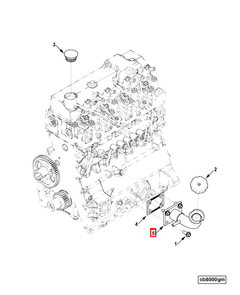

The 5291655 is an essential component in the arrangement of various engine systems, facilitating the smooth operation and maintenance of these systems.

Integration with Oil Fill System

The Oil Filler Tube is strategically positioned to interface with the oil fill system. It serves as the primary conduit for adding lubricant to the engine. This tube is connected to the oil tank and the engine’s lubrication system, ensuring that the oil reaches the necessary components without leakage or contamination.

Functionality in Engine Arrangement

In the engine arrangement, the Oil Filler Tube works in conjunction with several key components:

- Oil Tank: The tube extends from the oil tank, allowing for easy access during oil changes or top-ups.

- Dipstick Tube: Often integrated or adjacent to the Oil Filler Tube, the dipstick tube allows for oil level checks, ensuring the engine is adequately lubricated.

- Crankcase: The tube directs oil into the crankcase, where it is distributed to critical moving parts such as the crankshaft, camshaft, and pistons.

- Lubrication System: The Oil Filler Tube is a vital link in the lubrication system, ensuring that oil is efficiently circulated to reduce friction and wear on engine components.

Operational Synergy

The efficient design of the Oil Filler Tube enhances the overall synergy of the engine systems. It allows for quick and clean oil additions, minimizing downtime during maintenance. The tube’s secure fit prevents oil spills and ensures that the lubrication system operates within optimal parameters, contributing to the engine’s longevity and performance 4.

Conclusion

The Cummins 5291655 Oil Filler Tube is a critical component for maintaining the lubrication system in heavy-duty trucks. Its robust design, ease of use, and compatibility with various engine models make it an essential part for ensuring the efficient and reliable operation of truck engines. Proper installation, regular maintenance, and adherence to safety guidelines are key to maximizing the benefits of this part.

-

Quansheng Zhan, Shengbo Eben, Li Kun Deng. Automotive Heating Ventilation and Air Conditioning. Jones Bartlett Learning, 2018.

↩ -

Tom Denton and Hayley Pells. Automotive Technician Training, Second Edition. Routledge, 2022.

↩ -

Konrad Reif. Diesel Engine Management Systems and Components. Springer, 2014.

↩ -

Thomas Schuetz. Aerodynamics of Road Vehicles: Fifth Edition. SAE International, 2016.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.