This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

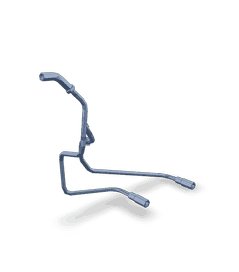

The Lubricating Oil Drain Tube (Part #5292368) by Cummins is a component designed for the maintenance of heavy-duty trucks. Its purpose is to facilitate the draining of used oil from the engine, which is a routine part of vehicle maintenance. The significance of this part lies in its role in ensuring that the engine operates efficiently and remains in good condition over time 1.

Function and Operation

The Lubricating Oil Drain Tube operates within the engine system by providing a pathway for used oil to exit the engine during an oil change. This process is vital for maintaining engine health, as it allows for the removal of contaminants and degraded oil that can accumulate over time. Regular oil changes are important for preserving engine performance and longevity, and the drain tube plays a role in this process by enabling a smooth and efficient oil drainage 2.

Key Features

This Cummins part is characterized by its durable construction and precise fit within the engine system. It is made from materials that are resistant to the corrosive effects of oil and the high temperatures within the engine compartment. The design of the tube ensures a secure connection to the engine, minimizing the risk of leaks. Additionally, the tube’s unique attributes contribute to its performance and longevity, making it a reliable component for heavy-duty applications 3.

Benefits of Using the Lubricating Oil Drain Tube

The Lubricating Oil Drain Tube offers several advantages. It provides efficient oil drainage, which reduces the time required for maintenance tasks. This efficiency can lead to decreased downtime for heavy-duty trucks, which is beneficial for fleet operations. Furthermore, the use of a well-designed drain tube contributes to overall engine efficiency and longevity by ensuring that oil changes are performed effectively.

Installation and Compatibility

Proper installation of the Lubricating Oil Drain Tube is important for its effective operation. Guidelines for installation include ensuring that the tube is correctly aligned with the engine’s oil pan and that all connections are secure. Specific requirements may vary depending on the engine model, and it is recommended to consult the manufacturer’s instructions for the most accurate information. A secure and effective fit within the engine system is crucial for the tube’s performance.

Maintenance and Troubleshooting

To ensure optimal performance of the Lubricating Oil Drain Tube, regular maintenance is necessary. This includes inspecting the tube for signs of wear or damage, such as cracks or corrosion, which could lead to leaks or blockages. Troubleshooting common issues may involve checking for proper alignment and ensuring that all connections are tight. Addressing these issues promptly can help maintain the efficiency of the oil drainage system.

Safety Considerations

When working with the Lubricating Oil Drain Tube, it is important to observe safety practices. This includes handling hot oil with care to avoid burns and using personal protective equipment, such as gloves and safety glasses. Additionally, ensuring that the work area is well-ventilated and that all tools are in good condition can contribute to a safe maintenance environment.

Environmental Impact

The disposal of used oil is an environmental consideration associated with the use of the Lubricating Oil Drain Tube. Responsible waste management practices involve recycling used oil whenever possible and disposing of it in accordance with local regulations. The tube’s role in facilitating efficient oil drainage can contribute to these practices by ensuring that oil changes are performed correctly and that used oil is collected for proper disposal.

Cummins: A Brief Overview

Cummins Inc. is a company with a history of manufacturing automotive components, including a range of parts for heavy-duty trucks. The company is known for its commitment to innovation and quality, which is reflected in the design and performance of its products. Cummins’ Lubricating Oil Drain Tube is part of a broader offering of components that are engineered to meet the demands of heavy-duty applications.

Cummins Engine Compatibility with Lubricating Oil Drain Tube Part 5292368

The Cummins part 5292368, a Lubricating Oil Drain Tube, is designed to fit seamlessly within a range of Cummins engine models. This part is integral to the maintenance and operational efficiency of these engines, ensuring that oil is properly drained and the system remains clean.

B6.7 CM2350 and B135B Engines

The B6.7 CM2350 and B135B engines are part of Cummins’ lineup that benefits from the use of the 5292368 drain tube. These engines are known for their robust performance and reliability, often used in heavy-duty applications. The lubricating oil drain tube is crucial in these engines for maintaining optimal oil levels and preventing contamination, which can lead to engine wear and reduced lifespan.

QSB6.7 M CM2250 Engines

Similarly, the QSB6.7 M CM2250 engines also utilize the 5292368 drain tube. This engine is another example of Cummins’ commitment to providing high-performance, durable engines for various applications. The drain tube in this engine model ensures that oil is efficiently drained, which is essential for maintaining engine health and performance.

The compatibility of the 5292368 drain tube across these engine models underscores its importance in the maintenance and operational protocols of Cummins engines. Ensuring that this part is correctly installed and maintained is vital for the longevity and efficiency of the engines.

Role of Part 5292368 Lubricating Oil Drain Tube in Engine Systems

The 5292368 lubricating oil drain tube is an essential component in maintaining the efficiency and longevity of engine systems. Its primary function is to facilitate the removal of used lubricating oil from the crankcase, ensuring that the engine operates with fresh oil that provides optimal lubrication and cooling.

Integration with the Crankcase

The crankcase is a vital part of the engine, housing the crankshaft and connecting rods. It is imperative that the crankcase maintains a clean environment free from contaminants and old oil. The 5292368 tube connects to the crankcase, allowing for the efficient drainage of oil during maintenance intervals. This process helps prevent the buildup of sludge and other impurities, which can adversely affect engine performance and lead to increased wear on moving parts.

Interaction with the Breather System

The breather system plays a significant role in regulating pressure within the crankcase. As the engine operates, gases and vapors are produced, which need to be expelled to maintain optimal pressure levels. The 5292368 tube works in conjunction with the breather system to ensure that the crankcase remains pressurized correctly. Proper pressure regulation is essential for the efficient operation of the piston rings and to prevent oil from being forced past the rings into the combustion chamber, which can lead to increased emissions and reduced engine efficiency.

Ensuring System Efficiency

By effectively draining used oil and interacting with the breather system, the 5292368 tube contributes to the overall efficiency of the engine system. Regular oil changes facilitated by this component help maintain the viscosity and lubricating properties of the oil, which are vital for reducing friction and wear on engine components. Additionally, the tube’s role in the breather system ensures that the crankcase operates under the correct pressure, which is essential for the proper functioning of the engine’s internal components.

Conclusion

The Lubricating Oil Drain Tube (Part #5292368) by Cummins is a critical component in the maintenance of heavy-duty trucks. Its role in facilitating efficient oil drainage, compatibility with various Cummins engine models, and contribution to engine system efficiency underscore its importance. Regular maintenance and proper installation of this part are essential for ensuring the longevity and performance of heavy-duty engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.